Automatic box falling device and operation method thereof

A box-dropping and automatic technology, applied in packaging and other directions, can solve problems such as a large amount of manpower, low work efficiency, and insufficient hygiene guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

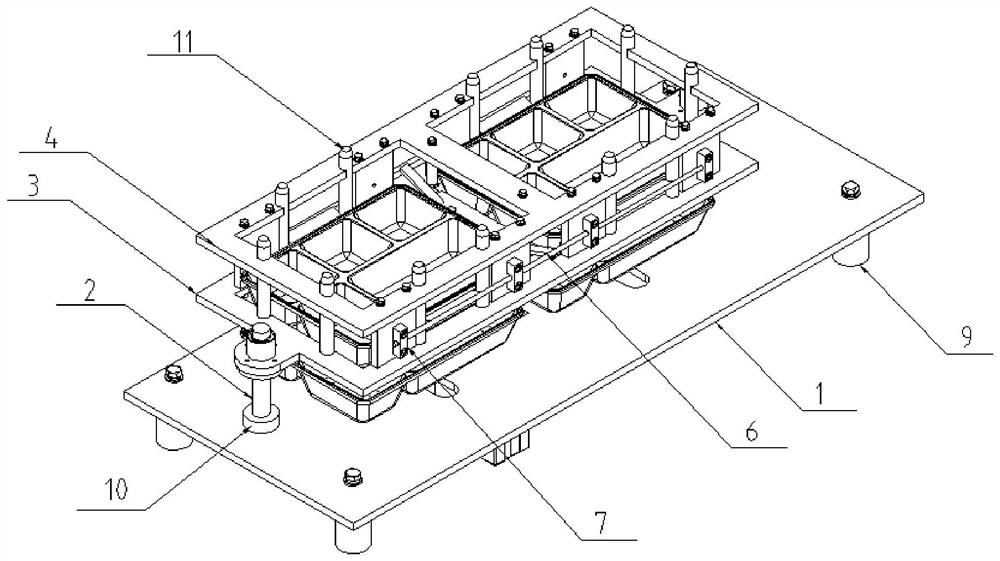

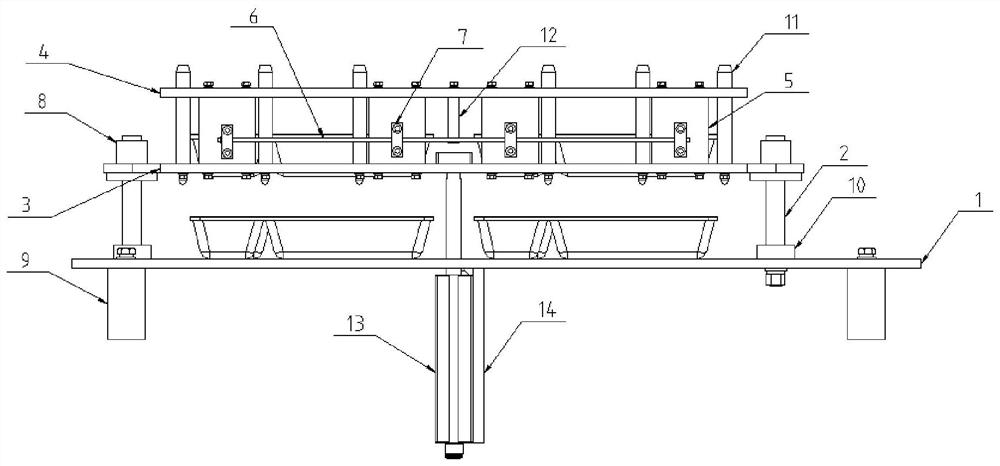

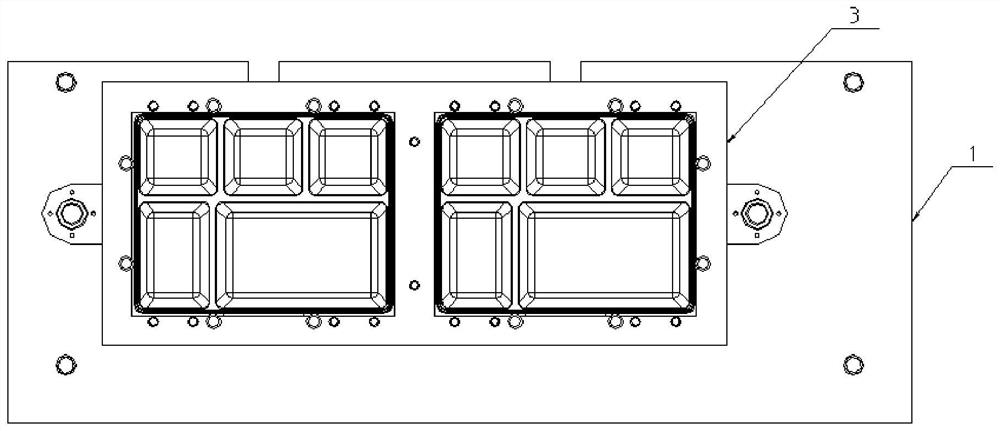

[0032] Please refer to figure 1 , figure 2 , image 3 and Figure 4 The schematic structural view of the first embodiment of an automatic box dropping device provided by the present application is shown, including: a bottom plate 1 arranged horizontally and a guide assembly arranged on the bottom plate 1;

[0033] The guide assembly includes: a first guide plate 3 and a second guide plate 4 arranged in parallel; the first guide plate 3 and the second guide plate 4 are correspondingly provided with at least two lunch box accommodating parts; Both sides of the lead-in plate 3 are affixed to the base plate 1 through the guide post 2 respectively; the top of the guide post 2 is provided with a linear bearing 8; the second guide plate 4 is located above the first lead-in plate 3, And it is affixed to the first lead-in plate 3 through the support blocks 5 evenly arranged; the second lead-in plate 4 is affixed with two symmetrically arranged lead-in swing shafts 6; the lead-in sw...

Embodiment 2

[0059] An operation method of an automatic box drop device, based on the above-mentioned automatic box drop device, comprising:

[0060] Step S1, the operator first puts the stacked lunch boxes into the lunch box accommodating part of the device;

[0061] Step S2, start the cylinder, its piston rod moves upwards, and drives the push block to move upward until the push block pushes the fixed end of the lead-in pendulum shaft, and the lead-in pendulum shaft moves, so that the lunch box at the bottom falls on the bottom plate, and the rest of the lunch boxes are lifted up ;

[0062] Step S3, the piston rod of the cylinder continues to extend to its maximum extension distance, so that the bottom of the remaining lunch boxes is higher than the top of the lunch boxes on the bottom plate, and the lunch boxes on the bottom plate are pushed away by the slider;

[0063] Step S4, the piston rod of the cylinder shrinks, so that a lunch box at the bottom of the lunch box accommodating par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com