Hairbrush strip and using method

A brush strip and conveying unit technology, applied in the field of logistics, can solve problems such as damage to items and missing parts, and achieve the effect of reducing jams and ensuring normal flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

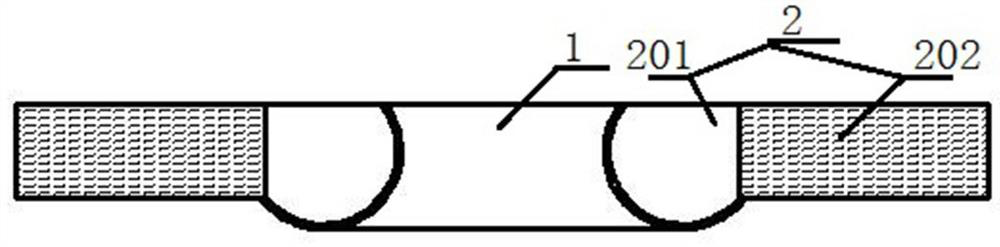

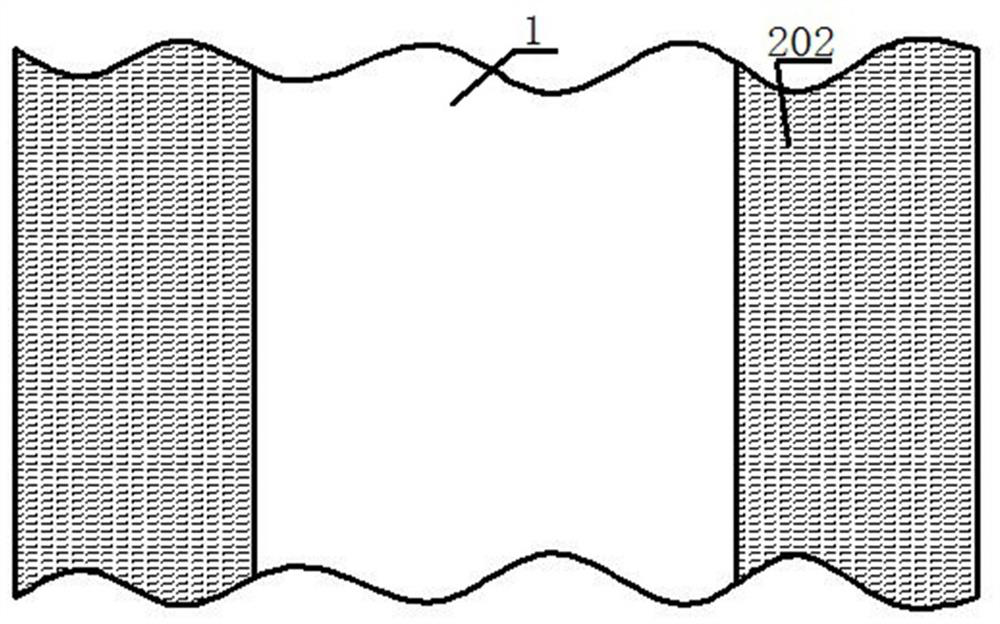

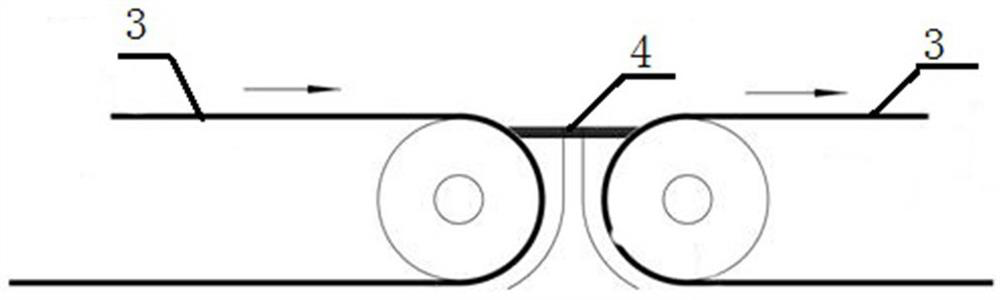

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a brush strip is used in the traditional conveyor line of the logistics industry, and is installed in the gap between the conveyor belts 3 of the two conveyor units in the conveyor line. A support frame is provided in the middle of the gap, including a fixed part 1 And the brush part 2; wherein:

[0021] Both sides of the fixed part 1 are provided with card slots, the brush part 2 includes a fixed rod 201 and bristles 202, one end of the bristles 202 is fixedly connected to the fixed rod 201, and the fixed rod 201 is placed in the card groove and fixed Part 1 is fixedly connected.

[0022] Preferably, the slots are arranged along the length direction of the fixing part 1 ; the length direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com