Demountable microtube array heat transfer performance tester

A heat transfer performance and test device technology, applied in the field of heat transfer, can solve the problems of non-reusable test device, increase test cost, and difficult processing, etc., achieve the effect of convenient disassembly and assembly, easy disassembly and assembly, and guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

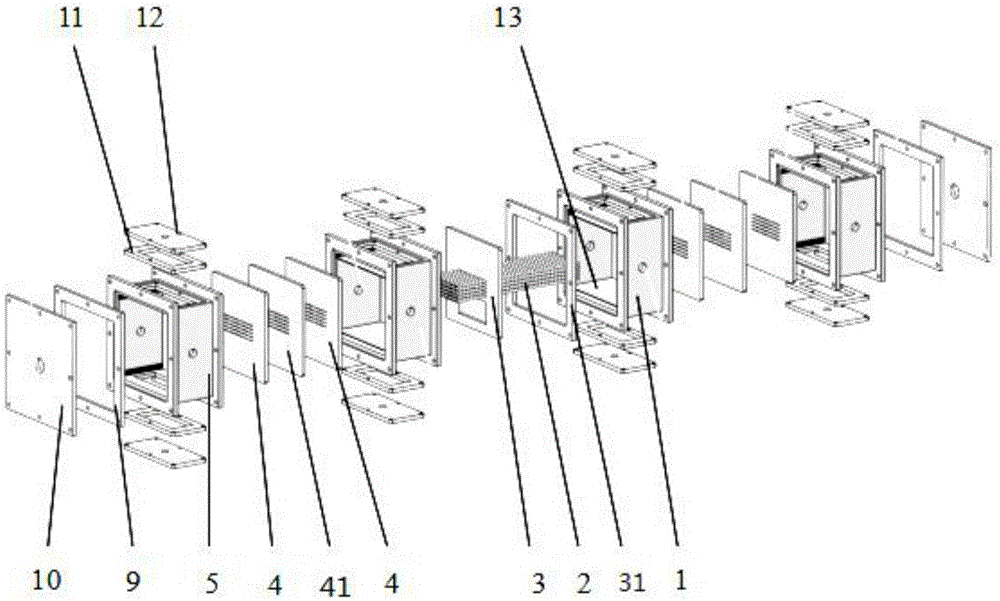

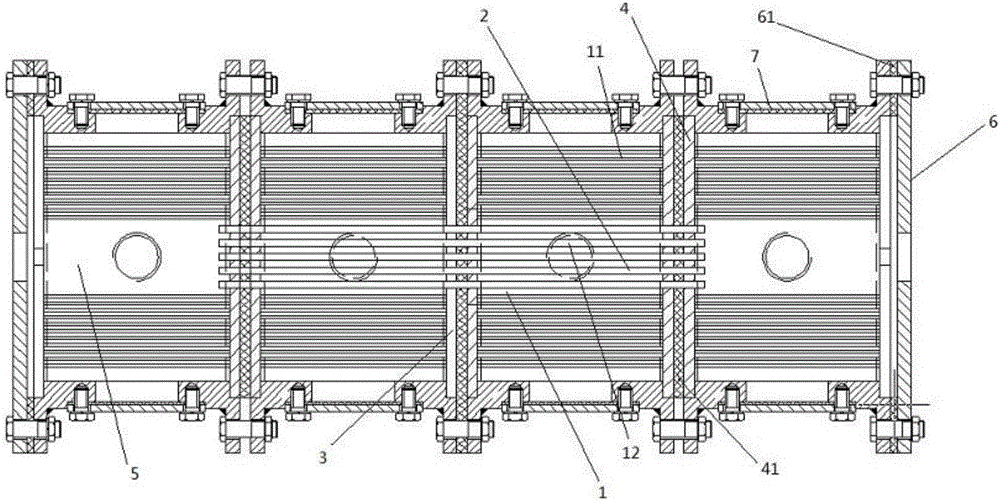

[0049] Embodiment 1: Structure and principle of micropipe array heat transfer performance test device of the present invention

[0050] Such as figure 1 , figure 2 As shown, the micropipe array heat transfer performance test device of the present invention is divided into a tube side and a shell side, wherein the shell side is mainly composed of a plurality of cylinder sections 1 connected to each other, and an end cylinder section 5 is respectively arranged at both ends of the shell side, The outer end of the end cylinder section 5 is sealed by the end cover 6, and the end cylinder section 5 communicates with the heat exchange tube 2 that is sheathed in the shell side to form a tube side.

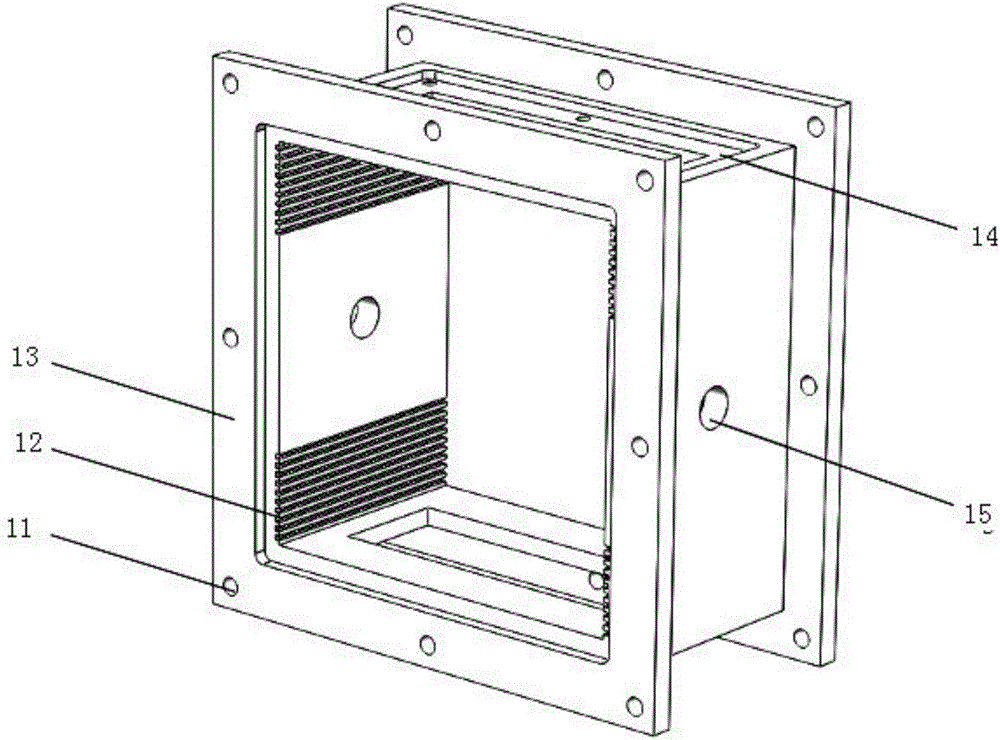

[0051] The cylindrical section 1 and the end cylindrical section 5 in the shell side have the same shape and structure, and are rectangular tubes, such as image 3 , The two ends of the barrel section are provided with flanges 13 with the same shape as the barrel section, and the barrel...

Embodiment 2

[0057] Embodiment 2: Design and processing of the main components of the micropipe array heat transfer performance test device

[0058] According to different experimental requirements, the size of the cylinder section also has different requirements. The specific determination steps are as follows:

[0059] The size of the barrel joint includes the side length and axial length of the barrel joint. The specification of heat exchange tubes (inner diameter and outer diameter), heat transfer area and volume flow rate of tube-side fluid are taken as the initial conditions for the design of the tube section.

[0060] First, according to the formula:

[0061]

[0062] and the formula:

[0063]

[0064] To determine the number and length of heat exchange tubes. (where n s - the number of heat exchange tubes; V - the volume flow rate of the tube side fluid; d i ―the inner diameter of the heat exchange tube; u i ―The flow rate of the fluid in the heat exchange tube; L—the l...

Embodiment 3

[0077] Embodiment 3: the assembly example of micropipe array heat transfer performance testing device of the present invention

[0078] The micropipe array heat transfer performance test device of the present invention is made up of four tube joints, will be as Figure 13 The test device composed of four equal-length barrel joints shown is one of the installation examples, and the specifications of the barrel joints are as follows: Figure 14 , 15 shown. Among them, the middle two shell-side cylinder sections 2 and 6 are connected to form the shell-side, and the shell-side is provided with a heat exchange tube 4; the two end cylinder sections 10 and 21 on both sides are used as the tube-side tube boxes of the test device for heat exchange. The inlet and outlet of the pipe extend into the barrel sections on both sides respectively, forming a tube path together with the end barrel sections.

[0079] During installation, the two cylinder sections 2 and 6 are firstly connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com