Reinforcing steel bar thread rolling device with automatic discharging function

An automatic feeding and distributing device technology, which is applied in the direction of feeding devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low efficiency and low safety of steel bar thread rolling machines, achieve novel and efficient device functions, and improve efficiency , The effect of simple processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

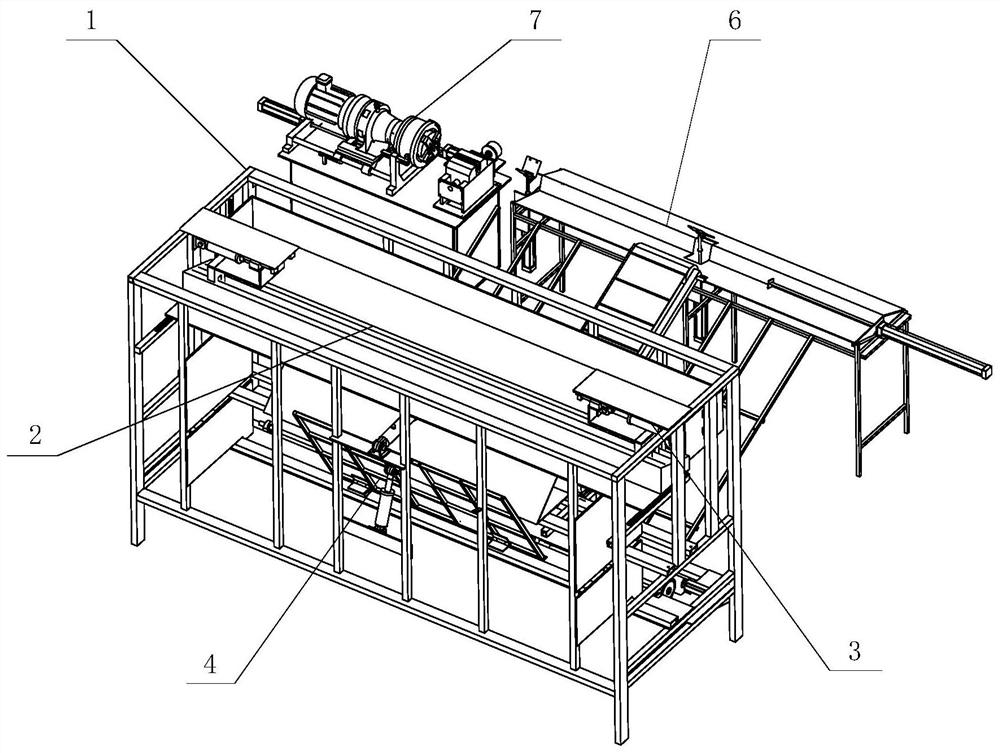

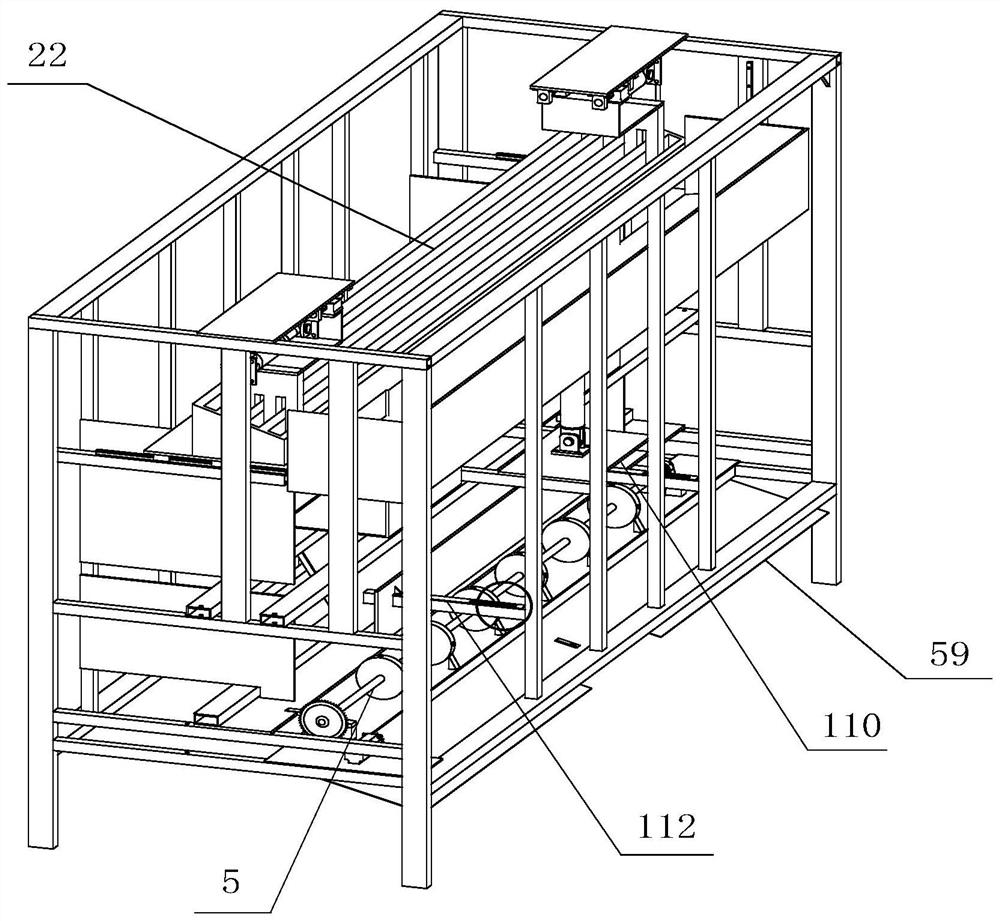

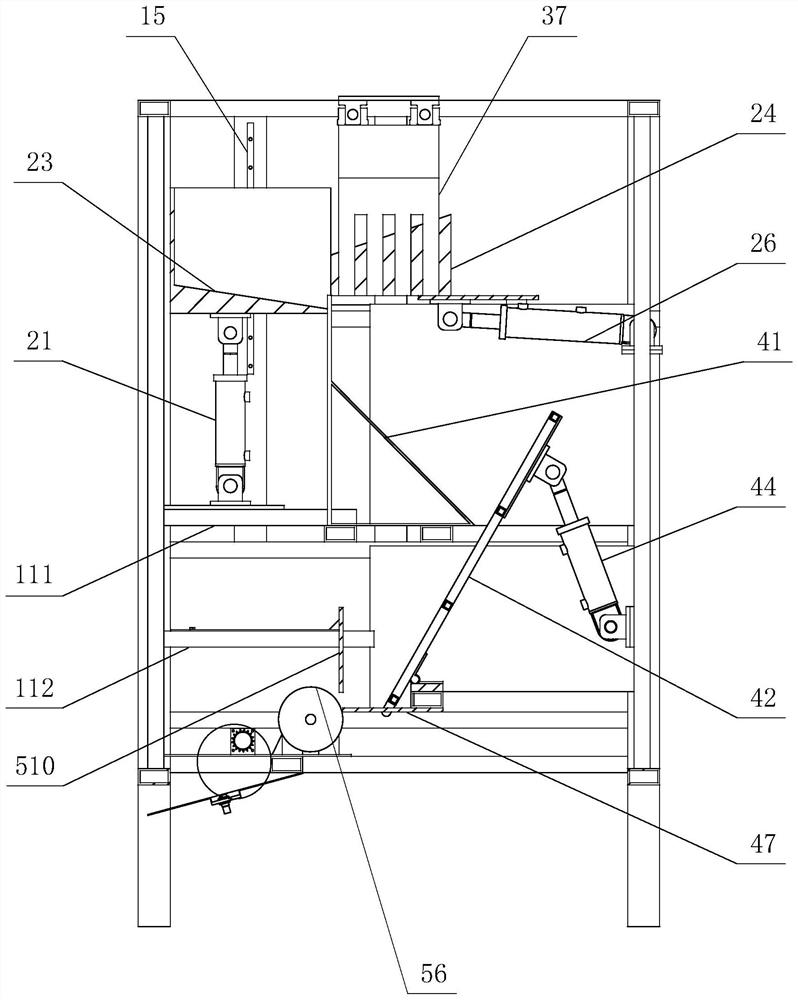

[0045] The invention provides a steel bar thread rolling device with automatic feeding function, such as Figure 1 ~ Figure 3 As shown, it includes a box body 1, a primary feeding device 2, a pushing device 3, a secondary feeding device 4, a magnetic feeding device 5, a feeding device 6 and an automatic thread rolling device 7, and the box body 1 is square steel The frame structure composed of steel plates, the primary material distribution device 2 is set on the top of the box body 1, and the material distribution box 24 in the primary material distribution device 2 is fixed in the middle of the top of the box body 1, and the right side of the material distribution box 24 The side is provided with a charging box 23, and the charging box 23 is slid on the vertical gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com