A device and method for detecting pits on the surface of a plate

A detection device and plate technology, which is applied to measurement devices, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as unqualified products, inability to accurately find pits, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

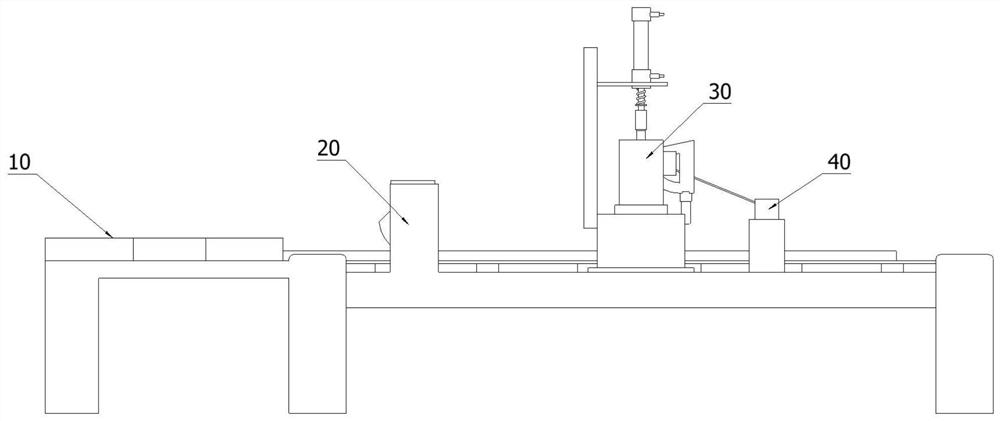

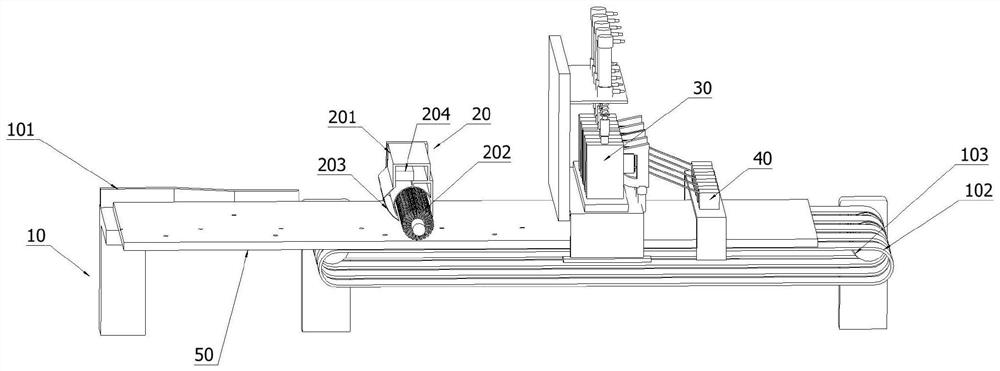

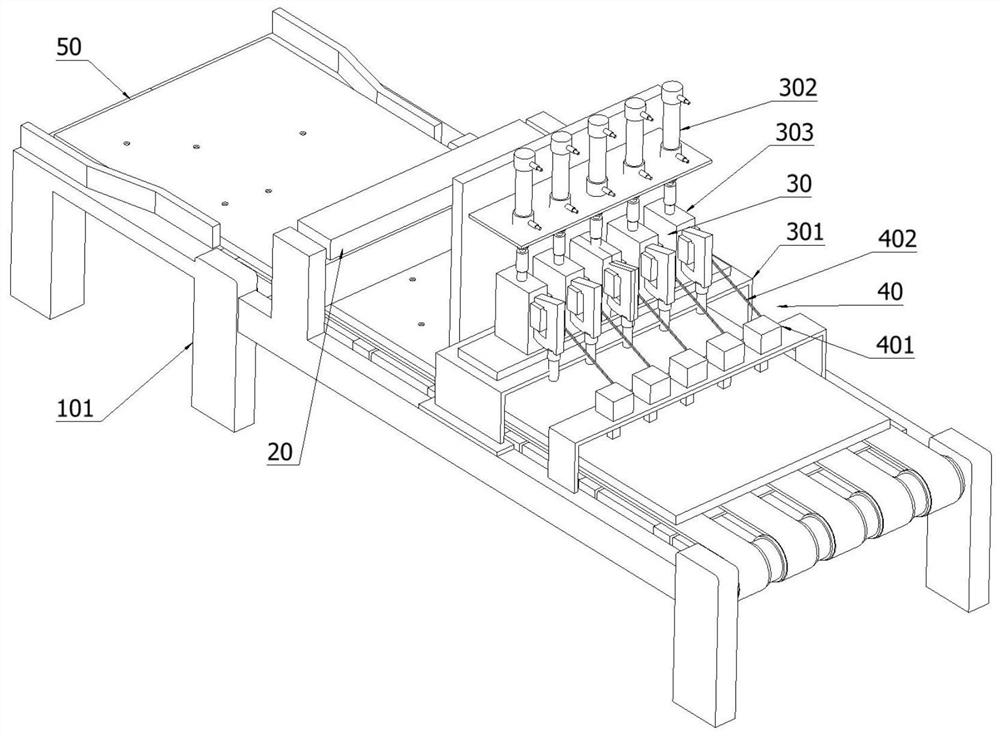

[0045] Such as figure 1 , 3 , 4, 5, and 6, this embodiment discloses a device for detecting pits on the surface of a plate 50, including: a body 10, a positioning device 30, the body 10 is arranged on a plane, and the body 10 includes: a transport frame 101, a rotating shaft 103 1. Conveyor belt 102, conveying frame 101 is arranged on the plane, and conveying frame 101 has certain height apart from the plane, and conveying frame 101 is divided into two sections, and one of them is the feeding section, and the other section is the feeding section, and the feeding section is positioned at the left side of body 10 side, the feeding section is located on the right side of the body 10; the surface of the feeding section is provided with a guide plate, the guide plate is arranged as a funnel, and the minimum port width of the guide plate is greater than the width of the plate 50; the rotating shaft 103 is arranged in the middle of the conveying frame 101, and the rotating shaft 103 ...

Embodiment 2

[0054] Same as Embodiment 1, also includes such as figure 2 , 3 As shown, the labeling device 40 is arranged on the right side of the positioning device 30 , the labeling device 40 is arranged above the feeding section of the machine body 10 , and the labeling device 40 is fixedly connected with the machine body 10 . The labeling device 40 includes: a labeling machine 401, a transmission line 402, the labeling machine 401 is arranged above the feeding section, the labeling machine 401 is connected to the support of the feeding section, and the labeling machine 401 is used for the positioning device 30 to locate the plate 50 Carry out labeling on the surface of the plate 50 during pits; the transmission line 402 is arranged in the middle of the labeling machine 401 and the positioning device 30, one end of the transmission line 402 is connected to the positioning device 30, and the other end of the transmission line 402 is connected to the labeling machine 401. Labeling machi...

Embodiment 3

[0058] Such as Figure 7 As shown, a detection method of a plate 50 surface pit detection device is provided, comprising the following steps:

[0059] Convey the plate 50, place the plate 50 on the feeding section of the conveying frame 101, move the plate 50 to the feeding section through an external push mechanism, and pass the plate 50 through the funnel opening of the feeding section before the plate 50 enters the feeding section. Position adjustment keeps the plate 50 feeding process stable;

[0060] To clean the surface, the brush 202 of the cleaning device 20 is rotated by an external driving device while the plate 50 is moving, and the surface of the plate 50 is rolled by the brush 202, and the surface of the plate 50 is brushed when the plate 50 is rolled. The removal of impurities does not affect the judgment of the positioning device 30, and the removed impurities flow into the inside of the cleaning case 201 through the suction pipe 203 through the suction fan 204...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com