Erecting, putting down and hoisting method for bulb tubular turbine generator stator

A hydro-generator, light bulb through-flow technology, applied in the directions of transportation, packaging, load hanging components, etc., can solve the problem of excessive roundness of the inner diameter of the iron core, and achieve the effect of improving safety and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the technical solutions of the present invention will be described in further non-limiting detail below in conjunction with specific embodiments.

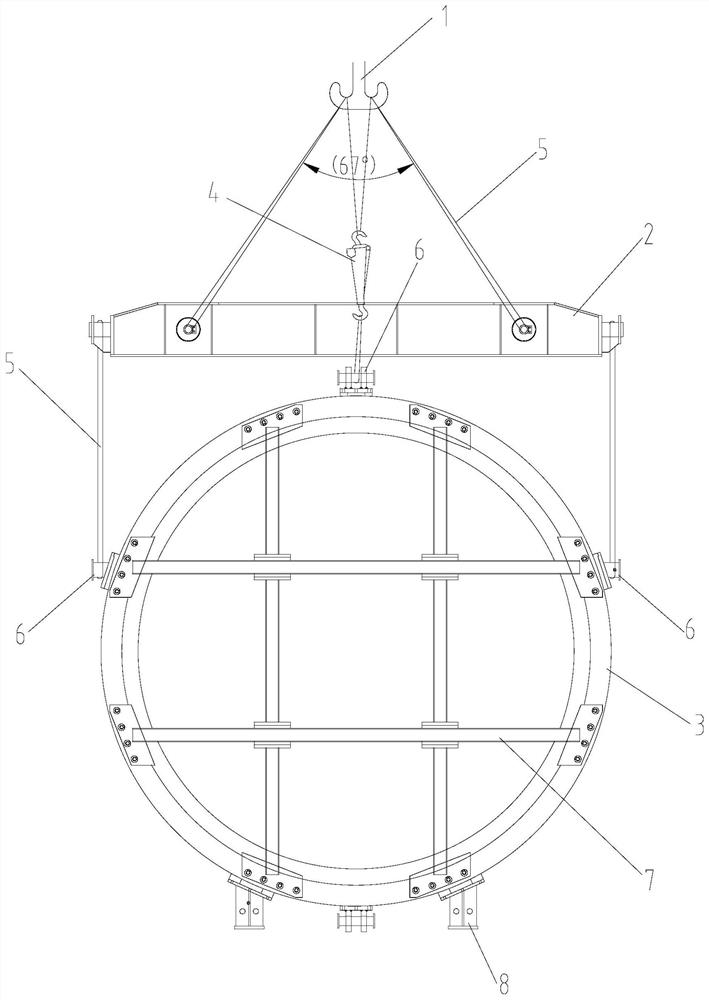

[0020] Such as Figure 1 to Figure 3 As shown, a method for erecting and hoisting the stator of a bulb tubular hydro-generator includes the following steps:

[0021] 1) Prepare the stator hanger. The stator hanger includes a crane, a balance beam 2, a chain hoist 4, two Φ72 steel wire ropes 5 and two Φ70 steel wire ropes 5, and the balance beam 2 is processed and cut according to the actual size of the generator orifice. The cut length of the balance beam 2 is not less than the distance between the two connecting ears 6 connected to it by the steel wire rope 5;

[0022] 2) Connect two Φ72 steel wire ropes 5 to the hoisting pin shaft on the main hook 1 of the crane and the balance beam 2, and the angle between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com