Electromechanical equipment mounting device and using method thereof

A technology of electromechanical equipment and installation device, which is applied in the direction of lifting equipment braking device, hoisting device, transportation and packaging, etc., to achieve the effect of improving safety performance and increasing fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

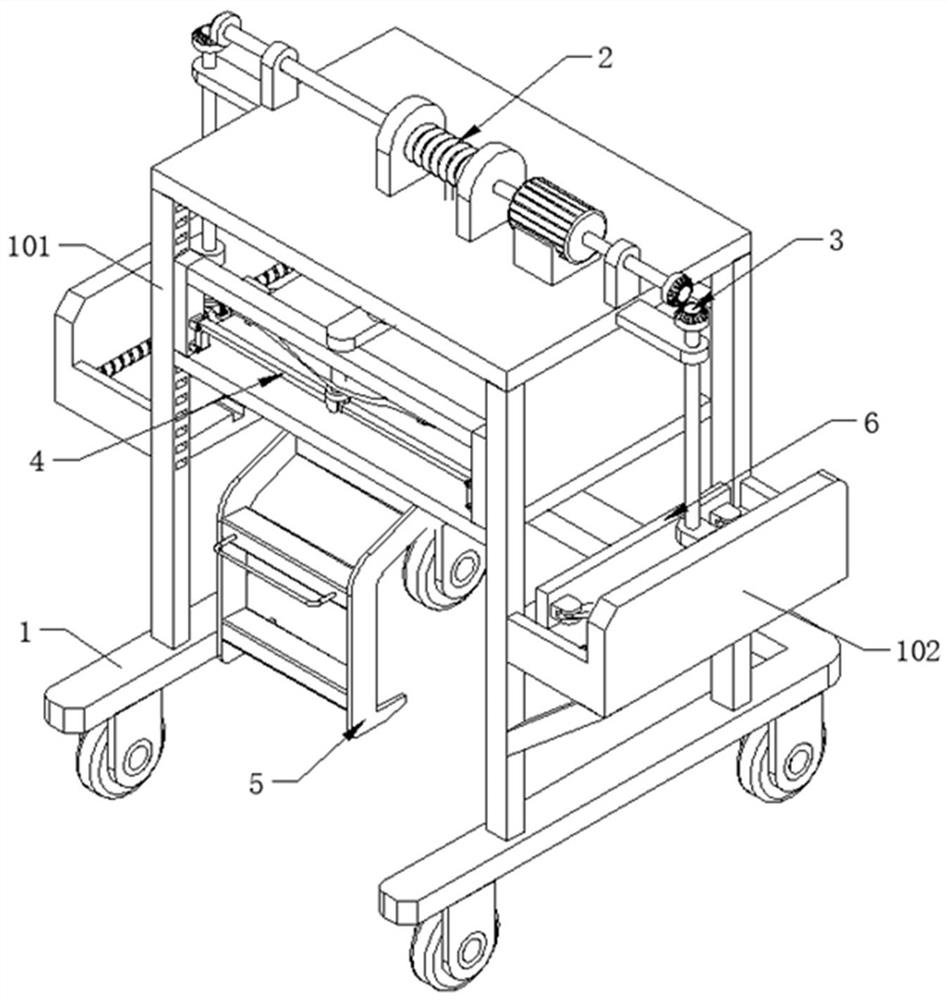

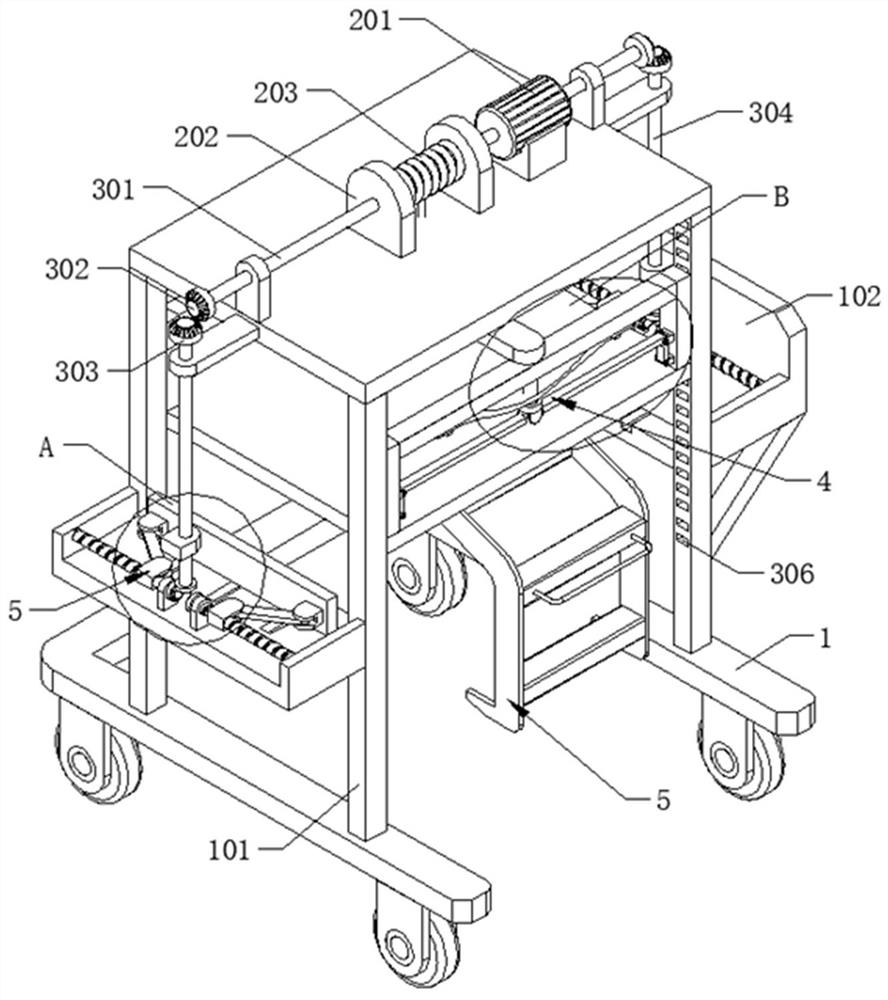

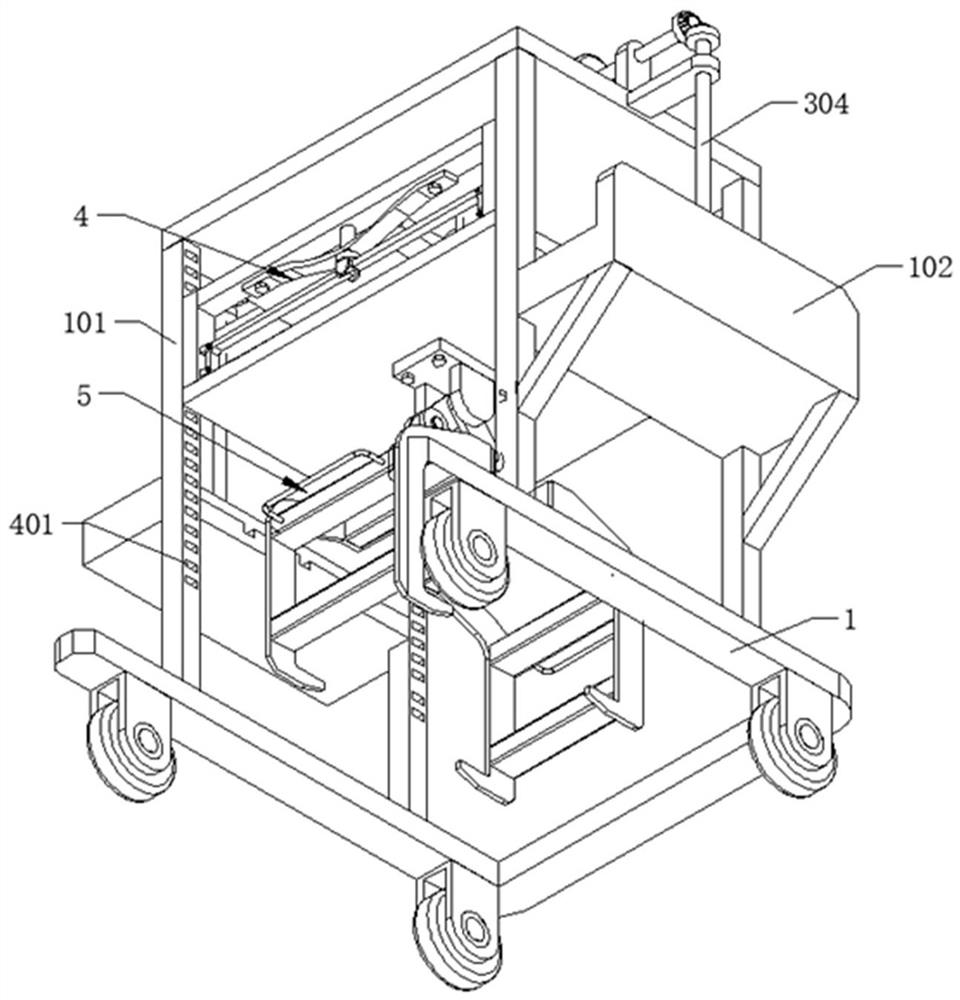

[0038] refer to Figure 1-7 , an electromechanical equipment installation device, including a U-shaped horizontal frame 1 and a first support frame 101, the first support frame 101 is connected to the top wall of the U-shaped horizontal frame 1, and a drive motor 201 is connected to the top wall of the first support frame 101 , the output end of the drive motor 201 is respectively connected to the lifting assembly 2 and the transmission assembly 3, the output end of the lifting assembly 2 passes through and is connected to the anti-fall assembly 4, the anti-fall assembly 4 is slidably connected to the inner wall of the first support frame 101, and the first The inner wall of the support frame 101 is dug with a card slot 401 matching the anti-fall assembly 4, the bottom wall of the anti-fall assembly 4 is connected with the first clamping assembly 5, and the transmission assembly 3 is connected to the side wall of the first support frame 101 through a fixing block. , and the en...

Embodiment 2

[0046] refer to Figure 1-5 , an electromechanical equipment installation device, which is basically the same as Embodiment 1, furthermore, the transmission assembly 3 includes a first rotating shaft 301, the first rotating shaft 301 is connected to the output end of the driving motor 201, and the first rotating shaft 301 is far away from the driving One end of the output end of the motor 201 is connected with a first bevel gear 302, the first bevel gear 302 is meshed with a second bevel gear 303, the second bevel gear 303 is connected with a second rotating shaft 304 on the bottom wall, and the second rotating shaft 304 bottom wall A third bevel gear 305 is connected to it, and a fourth bevel gear 306 is meshed with the third bevel gear 305 , and the fourth bevel gear 306 is connected with the second clamping assembly 6 .

[0047] The second clamping assembly 6 includes a threaded mandrel 602, one end of the threaded mandrel 602 is connected to the outer wall of the fourth be...

Embodiment 3

[0052] refer to Figure 1-7 , an electromechanical equipment installation device, which is basically the same as that of Embodiment 1, furthermore, the first clamping assembly 5 includes a second connection seat 501, and the second connection seat 501 is connected to the bottom wall of the fall prevention assembly 4, and the second A connecting rod assembly is rotatably connected to the inner wall of the connecting seat 501 , and the end of the connecting rod assembly away from the second connecting seat 501 is connected with a clamping claw 502 .

[0053] The connecting rod assembly includes a first connecting rod 503, a second connecting rod 504, a third connecting rod 505 and a fourth connecting rod 506, and the first connecting rod 503 and the second connecting rod 504 are rotatably connected to the second connecting rod through a first pivot pin. On the inner wall of the second connecting seat 501, and the first connecting rod 503 and the second connecting rod 504 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com