Movable pneumatic overturning auxiliary assembling device for engine butt joint overturning

A technology of auxiliary assembly device and turning device, which is applied in cranes, traveling mechanisms, transportation and packaging, etc., can solve the problem of high number of operators, high skill level and work experience requirements, and difficult applicability of spreaders to cover engine products and product production costs Improvement and other issues to achieve the effect of reducing work experience requirements, facilitating assembly and alignment, and strong assistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

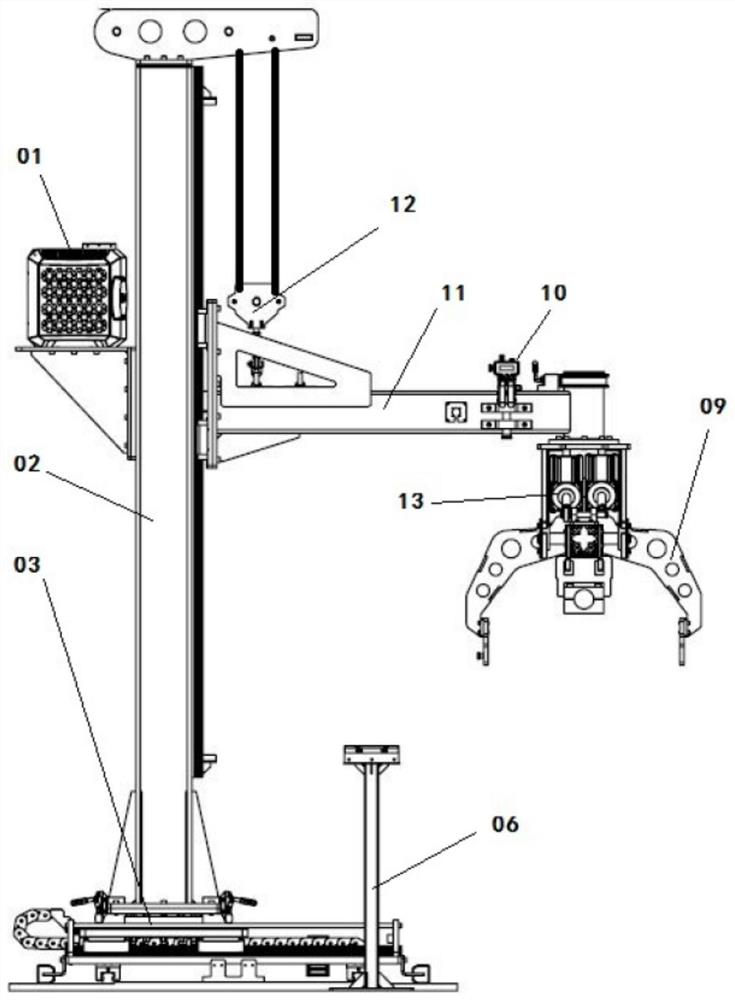

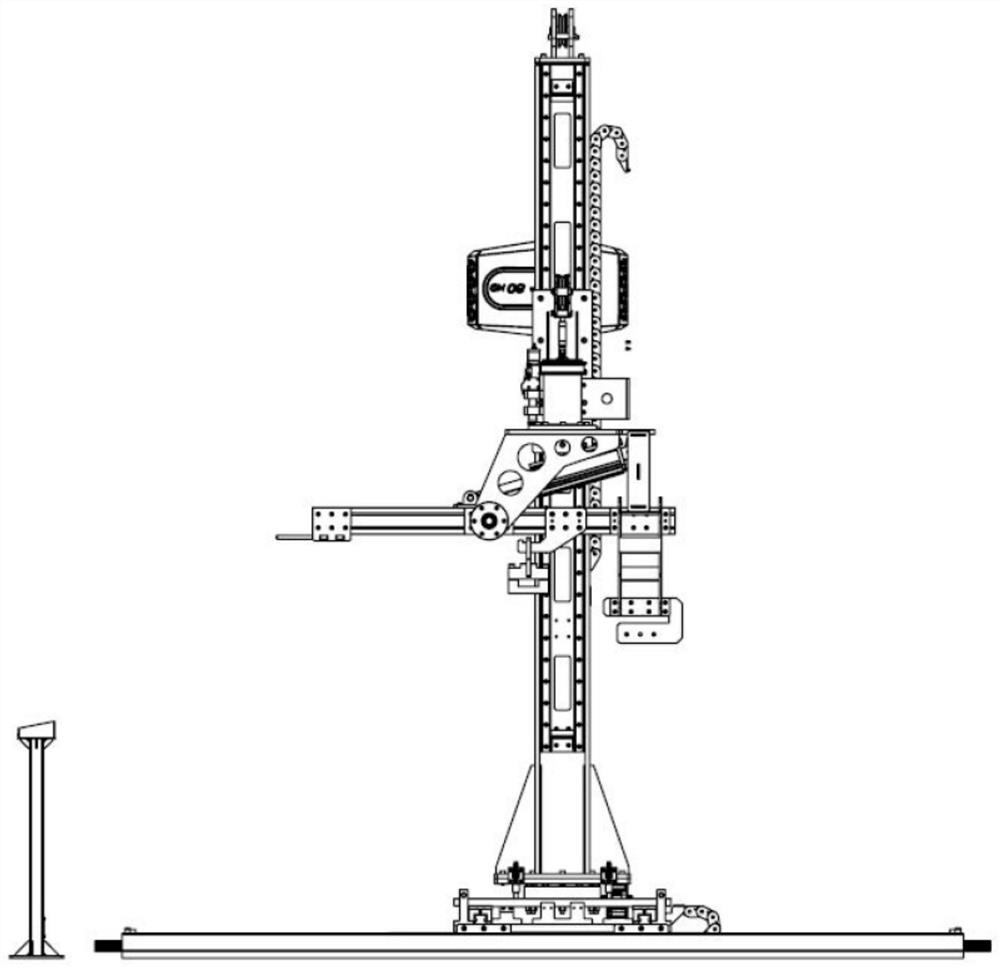

[0022] This embodiment provides a movable pneumatic overturning auxiliary assembly device for engine docking and overturning, such as figure 1 , figure 2 and image 3 As shown, the auxiliary assembly device includes a movable device, a lifting device and a pneumatic turning device.

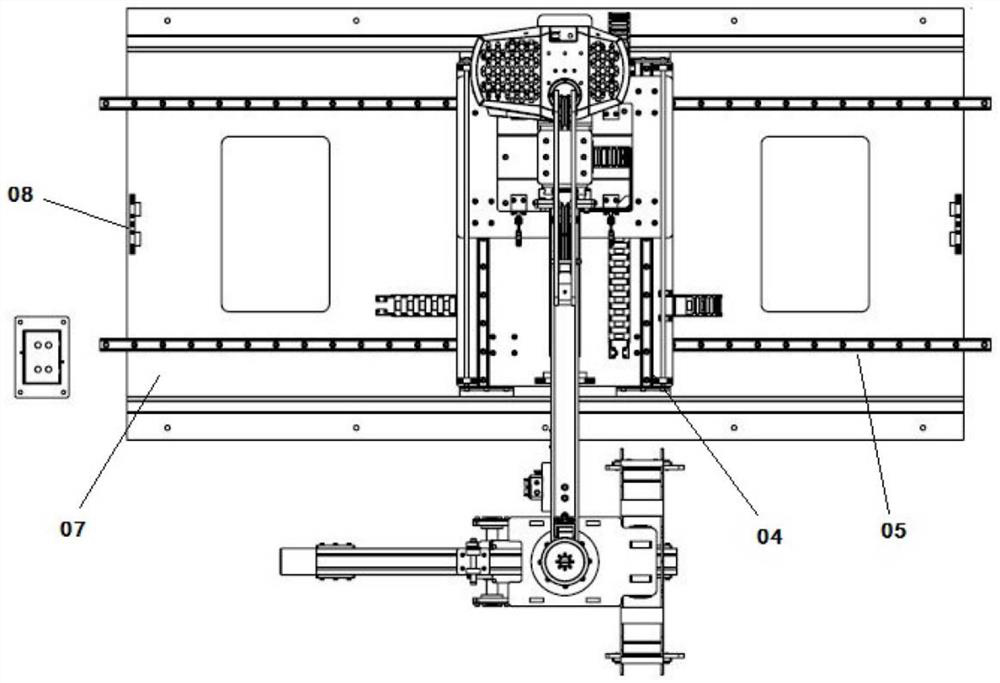

[0023] Movable device base 7, X-axis track 5, sliding platform I, Y-axis track 4, sliding platform II, positioning device, limit device 8 and slewing support 3.

[0024] The base 7 is fixed to the floor of the factory building, two rows of X-axis rails 5 are respectively arranged at both ends of the base 7, the sliding platform is installed on the X-axis rails 5, and moves along the X direction; two rows of Y-axis rails 4 are respectively arranged at both ends of the sliding platform, The Y-axis track 4 and the X-axis track 5 are vertical in the horizontal plane; the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com