Detection device and method for measuring movement of turbine flowmeter

A technology of turbine flowmeter and detection device, which is applied to devices using optical methods, testing/calibrating volume flow, etc., can solve the problems of increasing the manufacturing cost of flowmeters, high requirements, and time-consuming, so as to ensure reliability and overall Efficiency, Accurate Metrology Performance, Reduced Manufacturing Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

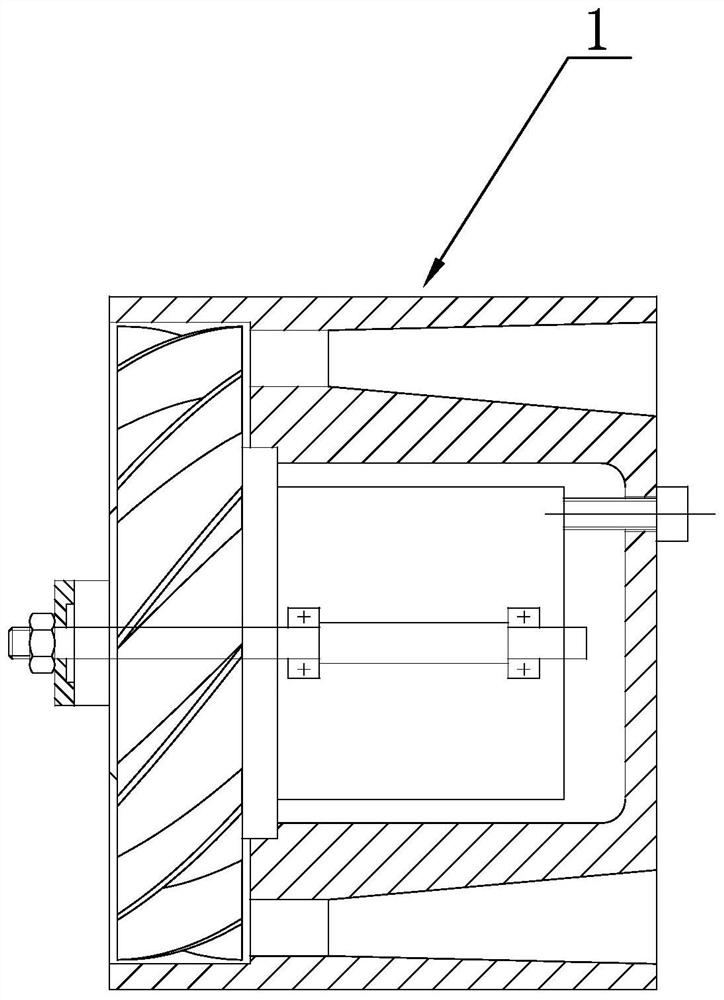

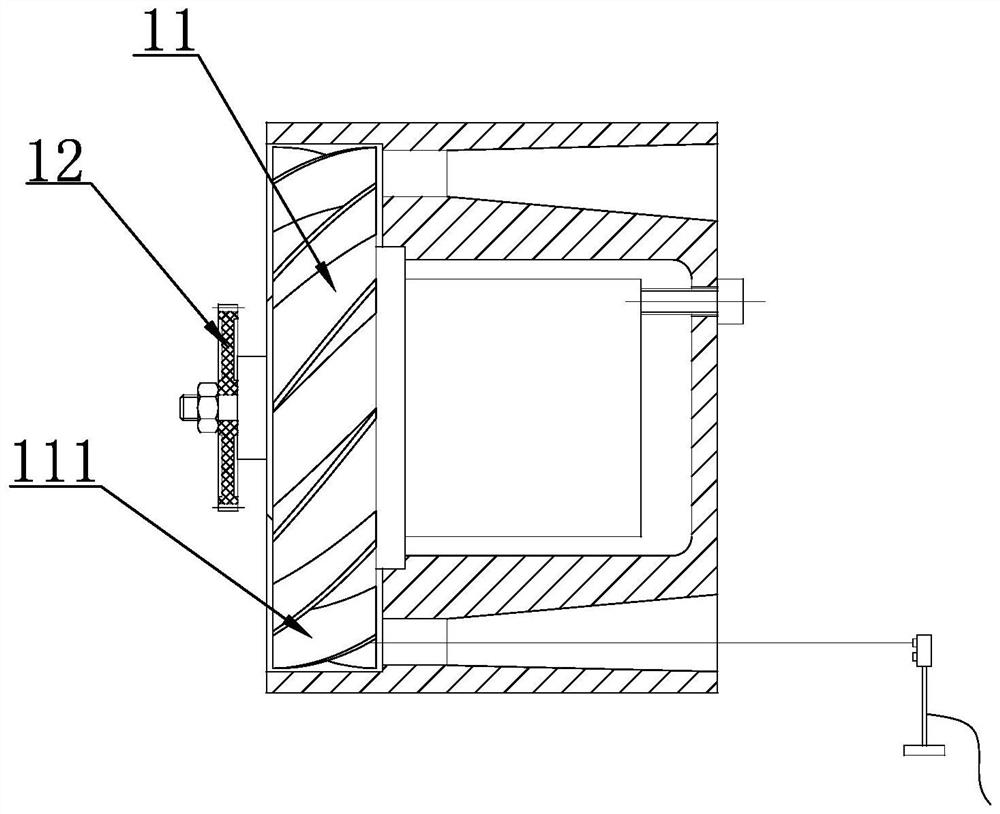

[0028] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

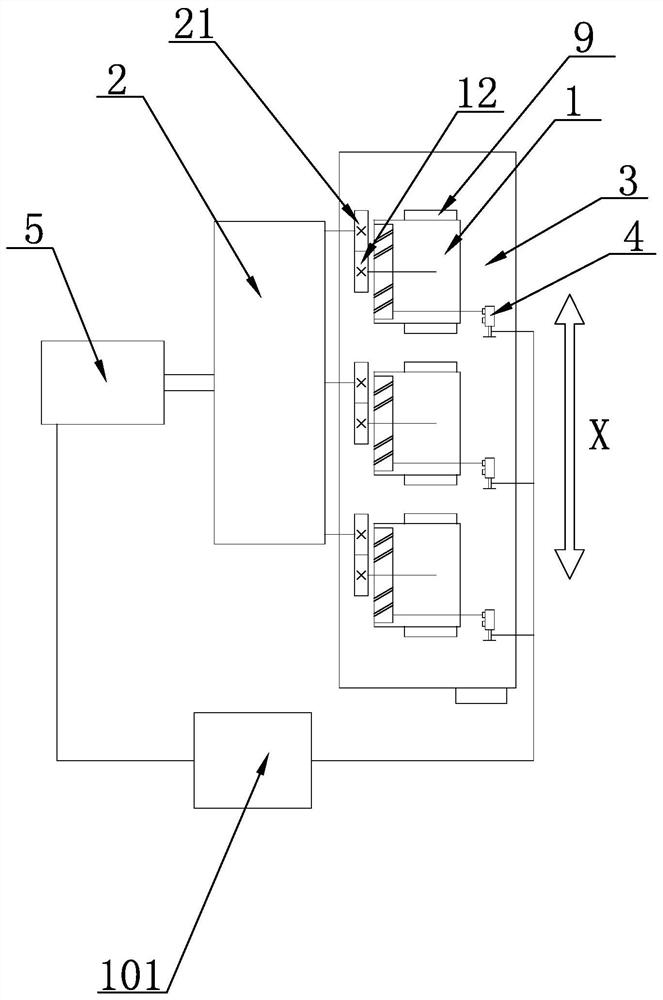

[0029] Mounting table 3 can be along the figure 1 The middle arrow reciprocates in the X direction. The specific installation method can be to use guide rails to slide or use other methods to guide the movement. The specific installation belongs to the common knowledge of those skilled in the art. This article will not introduce it in detail. The detecting movement is the measuring movement of the turbine flowmeter.

[0030] The disclosure of the present invention relates to a detection device for a measuring core of a turbine flowmeter. In an implementation case of the present invention, it includes:

[0031] The transmission device 2 is used to drive the transmission gear 12 to rotate. The output end of the transmission device 2 is provided with a drive gear 21, and the drive gear 21 cooperates with the output end of the transmission device 2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com