Polymer gel, particle size distribution monodisperse polymer microsphere and preparation and application thereof

A particle size distribution, polymer technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of unsatisfactory on-site implementation effect, unsatisfactory, high cost of polymer microspheres, etc., to improve the development effect , low cost, and the effect of improving water flooding recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

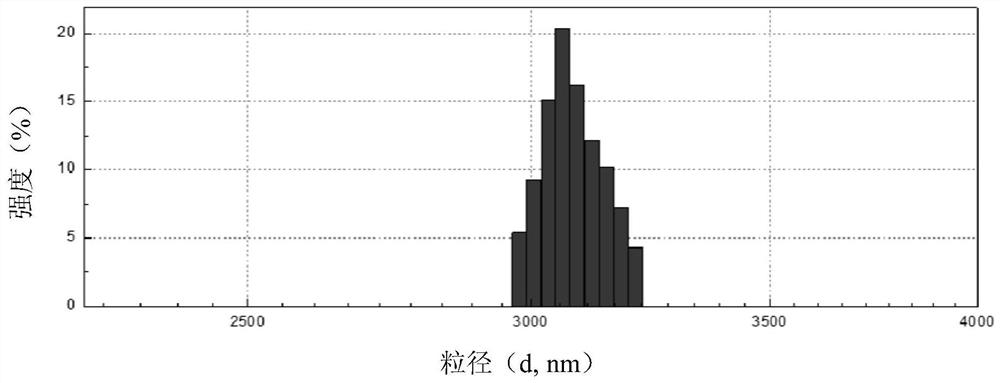

Embodiment 1

[0055]This embodiment provides a monodisperse polymer microsphere with particle size distribution for control and drive, wherein the preparation method of the monodisperse polymer microsphere with particle size distribution for control and drive comprises the following steps:

[0056] (1) Preparation of polymer gel:

[0057] Add successively the tap water of 99 parts by weight, the salt-resistant polymer (molecular weight is 8,000,000, degree of hydrolysis is 12%), the salicylaldehyde of 0.3 part by weight and the ammonium sulfate of 0.1 part by weight in tool plugged jar , after high-speed stirring to make it mix and dissolve, the resulting mixture was placed in a drying oven whose temperature was adjusted to 80° C., and the polymer gel was prepared after gelling, and its viscoelastic modulus G” was 8500 mPa·s.

[0058] (2) Preparation of monodisperse polymer microspheres with particle size distribution for adjusting and driving:

[0059] In the colloid mill, add 20 parts by...

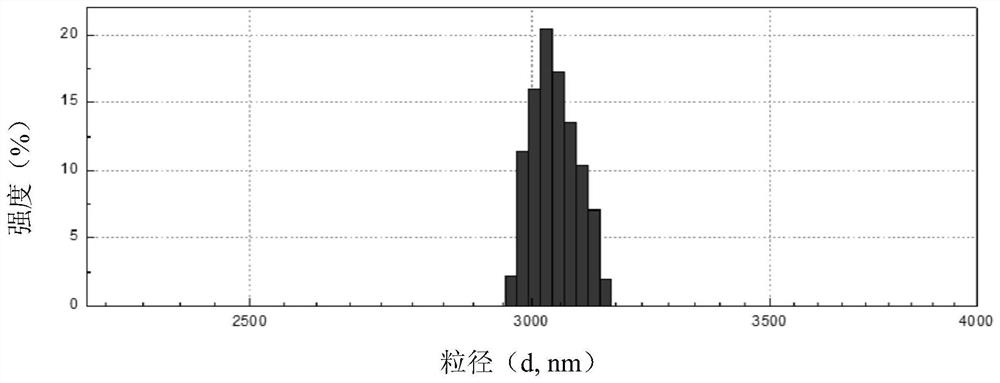

Embodiment 2

[0061] This embodiment provides a monodisperse polymer microsphere with particle size distribution for control and drive, wherein the preparation method of the monodisperse polymer microsphere with particle size distribution for control and drive comprises the following steps:

[0062] (1) Preparation of polymer gel:

[0063] Add successively the tap water of 99 parts by weight, the salt-resistant polymer (molecular weight is 8,000,000, degree of hydrolysis is 12%), the salicylaldehyde of 0.3 part by weight and the ammonium sulfate of 0.1 part by weight in tool plugged jar , after high-speed stirring to make it mix and dissolve, the resulting mixture was placed in a drying oven whose temperature was adjusted to 80° C., and the polymer gel was prepared after gelling, and its viscoelastic modulus G” was 8500 mPa·s.

[0064] (2) Preparation of monodisperse polymer microspheres with particle size distribution for adjusting and driving:

[0065] In the colloid mill, add 20 parts b...

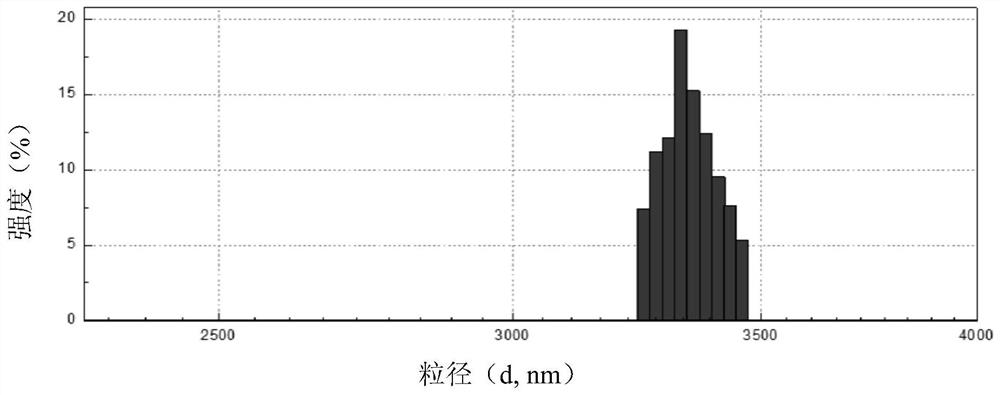

Embodiment 3

[0068] This embodiment provides a monodisperse polymer microsphere with particle size distribution for control and drive, wherein the preparation method of the monodisperse polymer microsphere with particle size distribution for control and drive comprises the following steps:

[0069] (1) Preparation of polymer gel:

[0070] Add successively the tap water of 99 parts by weight, the salt-resistant polymer (molecular weight is 8,000,000, degree of hydrolysis is 12%), the salicylaldehyde of 0.3 part by weight and the ammonium sulfate of 0.1 part by weight in tool plugged jar , after high-speed stirring to make it mix and dissolve, the resulting mixture was placed in a drying oven whose temperature was adjusted to 80° C., and the polymer gel was prepared after gelling, and its viscoelastic modulus G” was 8500 mPa·s.

[0071] (2) Preparation of monodisperse polymer microspheres with particle size distribution for adjusting and driving:

[0072] Add 30 parts by weight of the polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com