Construction method of asynchronous hanging basket for cast-in-place cantilever box girder with corrugated steel web

A corrugated steel web and construction method technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large safety hazards, long construction period and high cost, and achieve the effect of reducing time cost and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

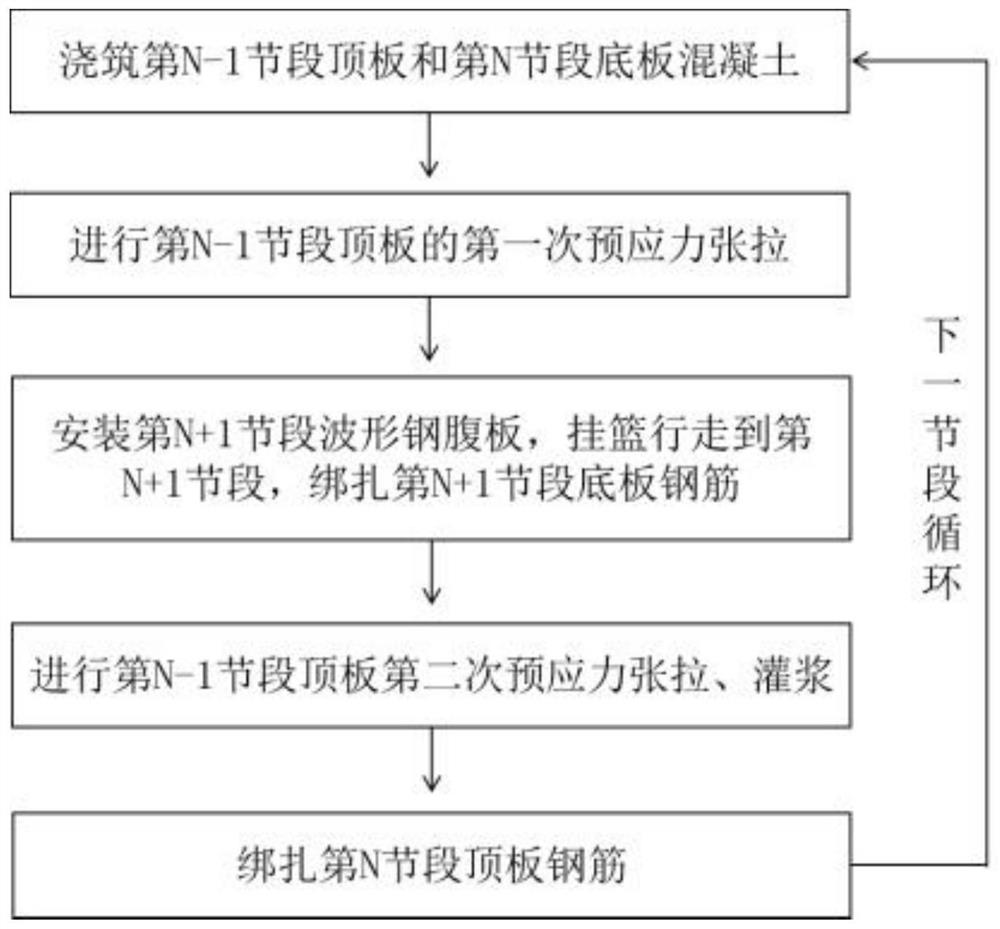

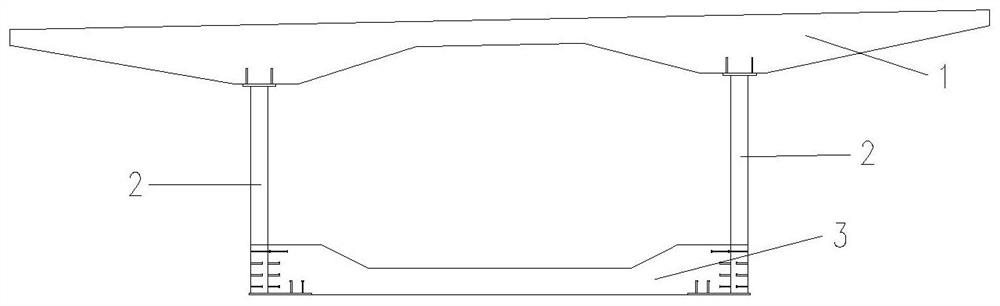

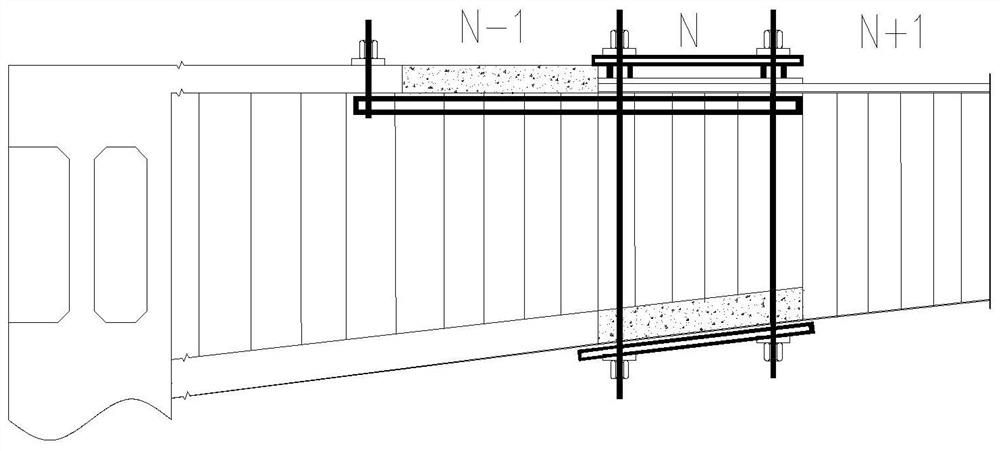

[0032] like Figure 1-3 As shown, a construction method of asynchronous hanging basket for cast-in-place cantilever box girder with corrugated steel web, the cross section of cast-in-place cantilever box girder with corrugated steel web is as follows figure 2 As shown, the top plate 1 and the bottom plate 3 are reinforced concrete, and the webs on both sides are corrugated steel webs 2 . Before the construction of the standard section of the bridge, block 0# needs to be constructed. After the top plate of block 0# is stretched, the corrugated steel web of block 1# is installed, and then the hanging basket is assembled, and the steel bars of the bottom plate of block 2# and block 1# are bound. The roof reinforcing bar, then start to circulate according to the standard segment provided by the present invention, comprise the following steps:

[0033] (1) Concrete is poured for the top slab of section N-1 and the bottom slab of section N. like image 3 As shown, the roof formw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com