A highly reliable soluble bridge plug

A reliable and soluble bridge technology, applied in wellbore/well components, production fluid, sealing/isolation, etc., can solve problems such as long waiting time for dissolution, decreased reliability of slip anchoring, bridge plug slippage, etc. Achieve the effects of saving waiting time, improving the efficiency of fracturing operations, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

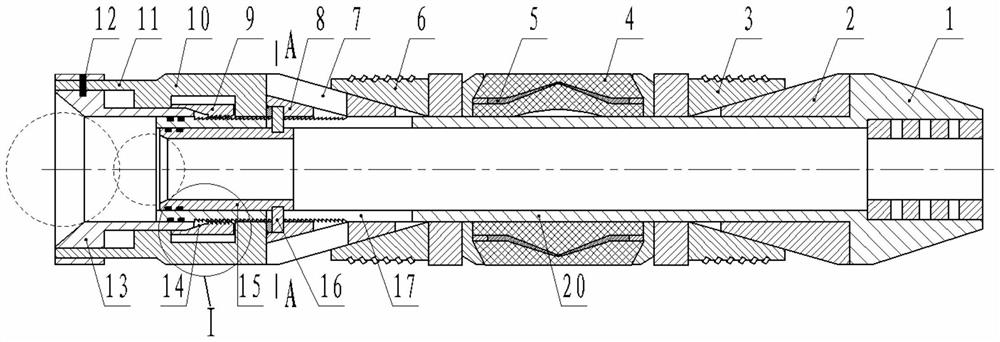

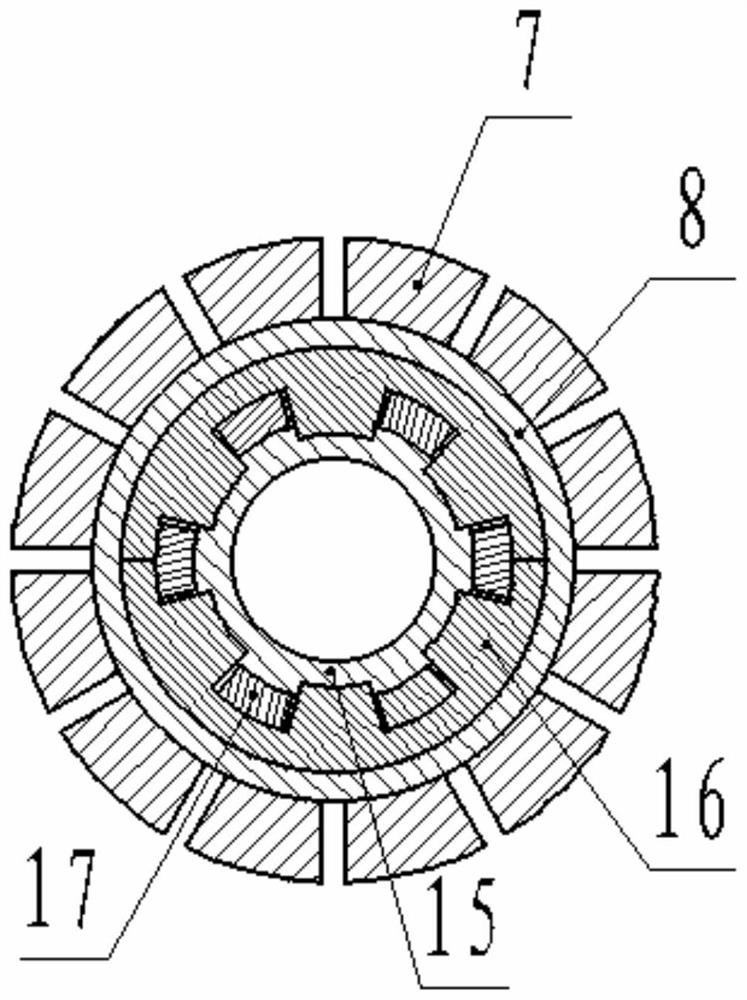

[0020] The present invention includes a mandrel 20, a rubber cartridge 4, an upper slip 6, a lower slip 3, an upper vertebral body 7 and a lower vertebral body 2, and the mandrel 20 is a hollow structure. The above are common structures in the prior art, and will not be repeated here.

[0021] The most important innovation of the present invention is: the lower end of the mandrel 20 is provided with a limiting part 1, the lower side of the limiting part 1 is a conical surface, and the conical surface plays the role of guiding shoes, which is more conducive to going down the well. The lower vertebral body 2, the lower slips 3, the rubber tube 4, the upper slips 6, and the upper vertebral body 7 are sequentially fitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com