Arc extinguishing mechanism for circuit breaker, and circuit breaker

A circuit breaker and arc extinguishing technology, applied in circuit breaker parts, circuits, electrical components, etc., can solve the problems of potential safety hazards, slow arc airflow movement, slow down the speed of arc extinguishing, etc., to avoid potential safety hazards, The effect of balanced movement speed, accelerated speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

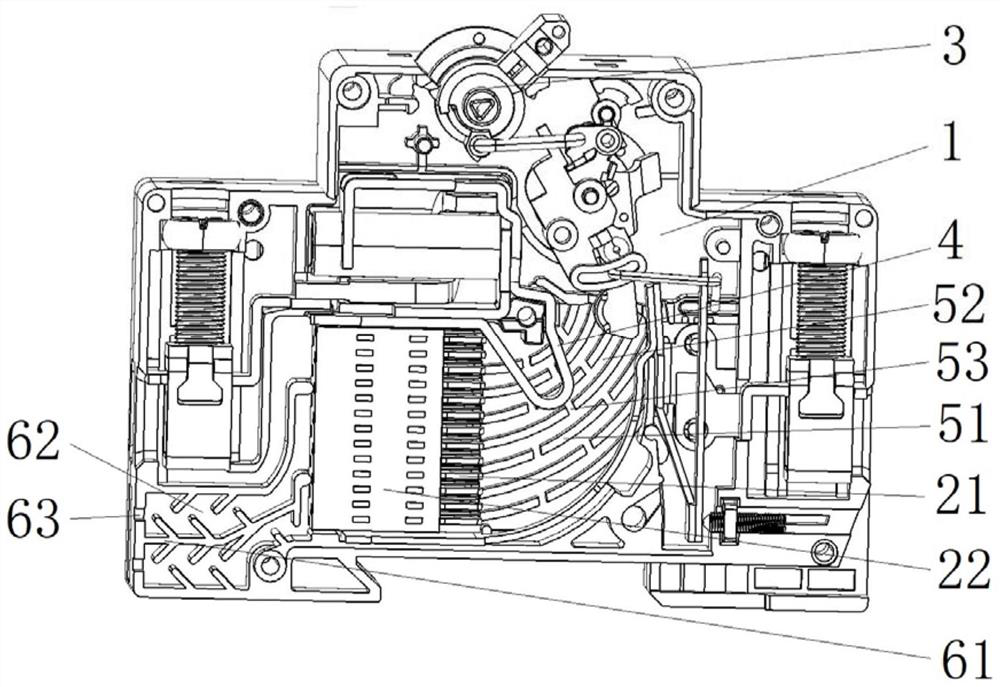

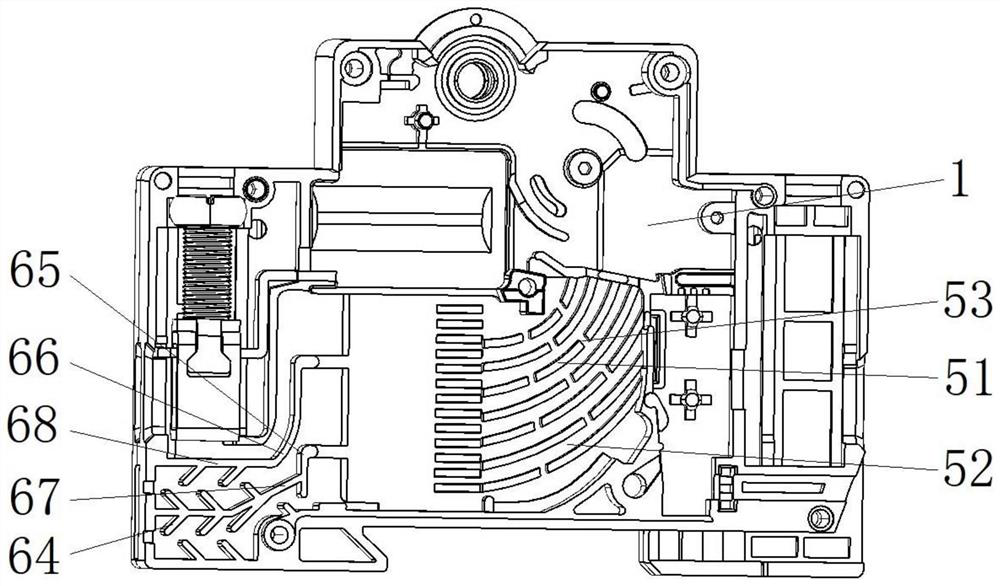

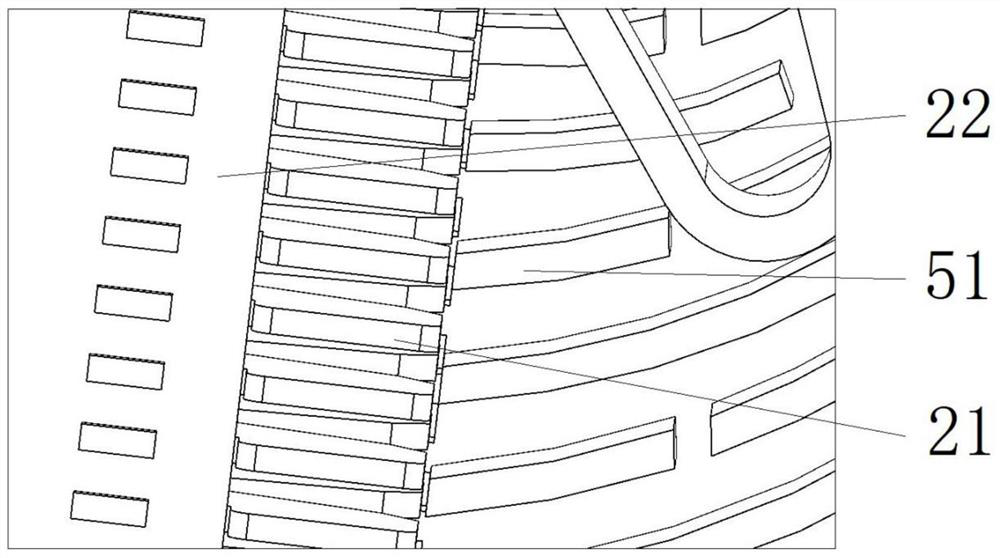

[0042] This embodiment provides a Figure 1 to Figure 4 The shown arc extinguishing mechanism for a circuit breaker includes: a housing 1, an arc extinguishing chamber, an arc striking structure and an exhaust arc extinguishing structure. Wherein the arc extinguishing chamber is arranged in the housing 1, including a plurality of arc extinguishing grids 21 and an arc extinguishing installation housing 22, the arc extinguishing grids 21 are installed on the arc extinguishing installation housing 22, and the arc extinguishing installation housing 22 is provided with There is an air outlet 23; the arc starting structure is set in the housing 1 and is located on the side of the arc extinguishing chamber close to the contact mechanism 4; the exhaust arc extinguishing structure is located in the housing 1 and is located on the side of the arc extinguishing chamber away from the contact mechanism 4 On one side, the arc is discharged from the shell 1 through the exhaust arc extinguish...

Embodiment 2

[0053] This embodiment provides a circuit breaker, including the arc extinguishing mechanism for the circuit breaker mentioned in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com