Sorting mechanical hand and sorting system

A technology of a manipulator and a lifting drive mechanism, applied in the field of logistics sorting equipment, can solve the problems of time-consuming and laborious, high labor cost, and increasing the complexity of the sorting system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

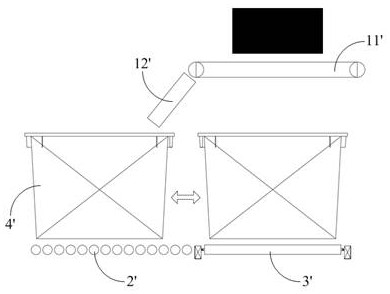

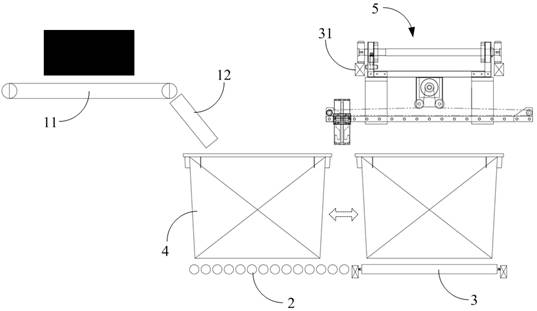

[0043] Please refer to the attached figure 2 , attached Figure 5-6 , a sorting system is proposed in the embodiment of the present invention, the sorting system includes a sorting conveyor line and a circulating drum line 3, the circulating drum line 3 is located below the outside of the sorting conveyor line, and the outside of the sorting conveyor line is provided with There are multiple sorting grid positions, and the outer side of the circulating drum line 3 is provided with a carrying drum line 2 corresponding to each sorting grid position, and the carrying drum line 2 and the sorting grid position are connected through a sorting slide 12 .

[0044] A turnover box 4 is placed on the carrying roller line 2. When the sorting trolley 11 on the sorting conveyor line transports the parcel to the designated position, the parcel can be sent out and dropped to the turnover box 4 at the corresponding position through the sorting chute 12 Inside.

[0045] A track 31 is arrange...

Embodiment 2

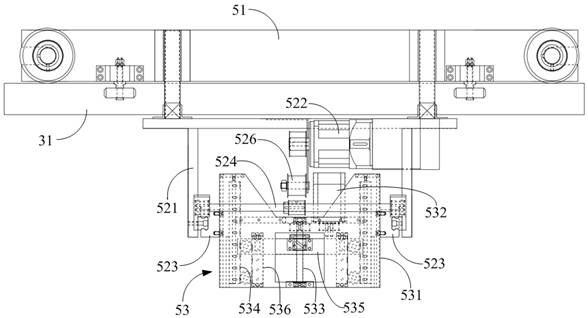

[0067] On the basis of Example 1, such as Figure 9-10 As shown, in this embodiment, the sorting manipulator 5 also includes a lifting and intercepting mechanism 55 arranged under the car body 51 and used to intercept the turnover box 4 on the circulating drum line 3 and move along the sorting direction. As a result, before the turnover box 4 reaches the bottom of the sorting manipulator 5, the further movement of the turnover box 4 can be prevented by driving the lifting interception mechanism 55 to protrude downward, and the circulating roller line 3 can also maintain normal operation without having to transfer the turnover box. Pause at 4 to further improve sorting efficiency.

[0068] Optionally, as in Figure 7-8 As shown, in this embodiment, the lifting interception mechanism 55 includes a vertical plate 551 , a third motor 552 , a second screw rod 553 and a baffle 554 . It should be noted that, Figure 8 The first motor 522 and the transmission parts matched with it ...

Embodiment 3

[0078] Please refer to the attached Figure 11 , the embodiment of the present invention proposes another sorting system, the sorting system includes a sorting conveyor line and a circulating drum line 3, the circulating drum line 3 is located directly below the sorting conveyor line, and the two sides of the sorting conveyor line are respectively There are multiple sorting grid positions, and the two sides of the circulating drum line 3 are provided with a load-bearing drum line 2 corresponding to each sorting grid position. Road 12 connects.

[0079] A turnover box 4 is placed on the carrying roller line 2. When the sorting trolley 11 on the sorting conveyor line transports the parcel to the designated position, the parcel can be sent out and dropped to the turnover box 4 at the corresponding position through the sorting chute 12 Inside.

[0080] A track 31 is arranged above the circulating drum line 3 , and a sorting manipulator 5 is arranged on the track 31 . When the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com