Multifunctional nut applied to concrete wall

A concrete wall and multi-functional technology, which is applied to the preparation of building components on site, the connectors of formwork/formwork/work frame, construction, etc., can solve the problems of poor project quality, insufficient maintenance, and high maintenance costs. Achieve the effect of low thermal conductivity and reduce the probability of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

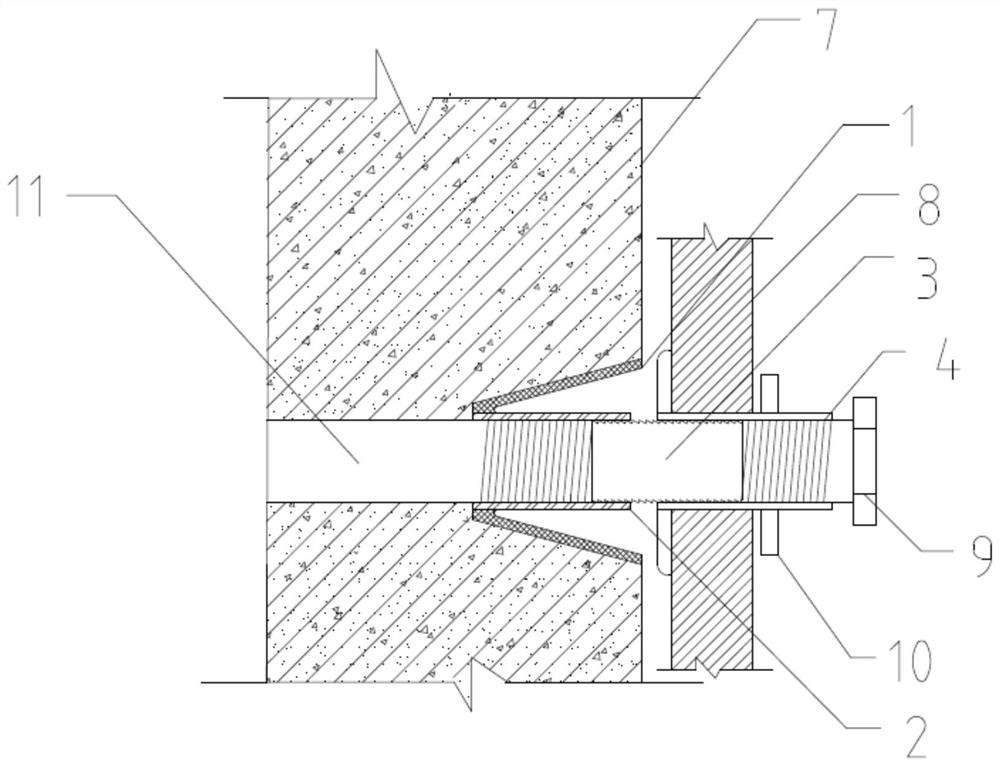

[0036] combined with Figure 1-7 , a multifunctional nut applied to concrete walls, comprising a water-stop screw 11, a tapered nut part screwed to the water-stop screw 11, and a screw affixed to one end of the tapered nut part opposite to the water-stop screw 11 Part 1, screw part 2 and screw part 3 interconnected with screw part 2, wherein,

[0037] One end of the water-stop screw rod 11 is provided with an external thread adapted to a special-shaped nut;

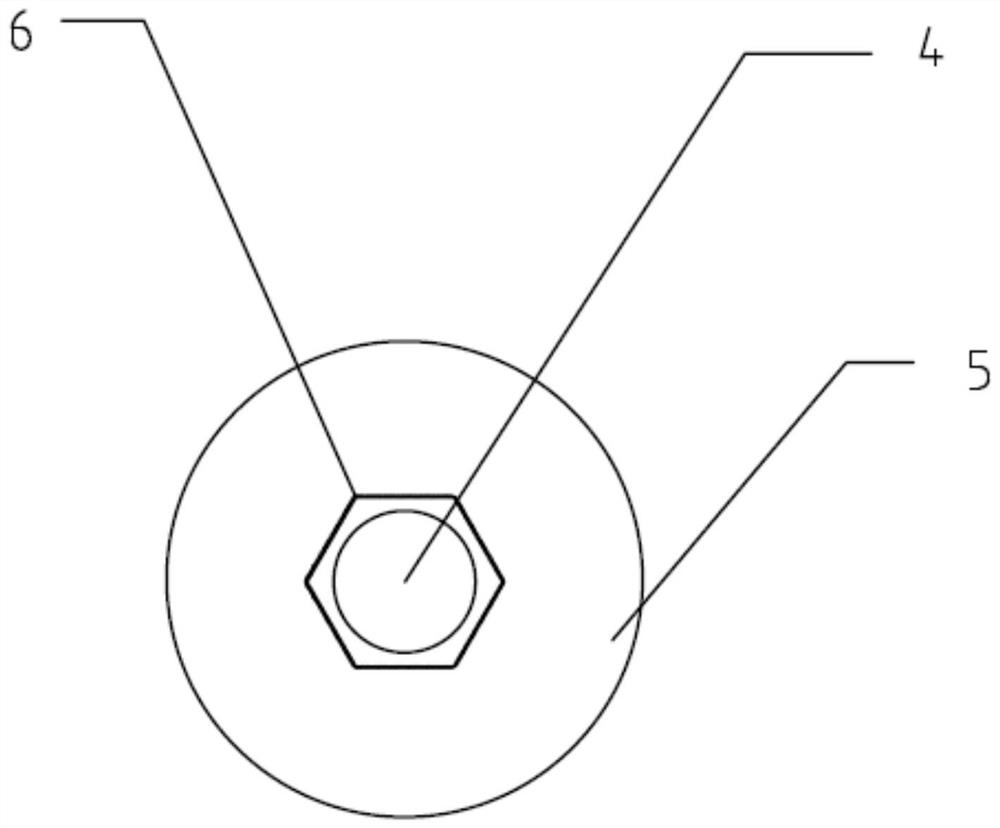

[0038] The tapered nut part includes a special-shaped nut 1, the special-shaped nut 1 gradually becomes thicker from one end to the other end, and the thinner end is affixed to the screw part one;

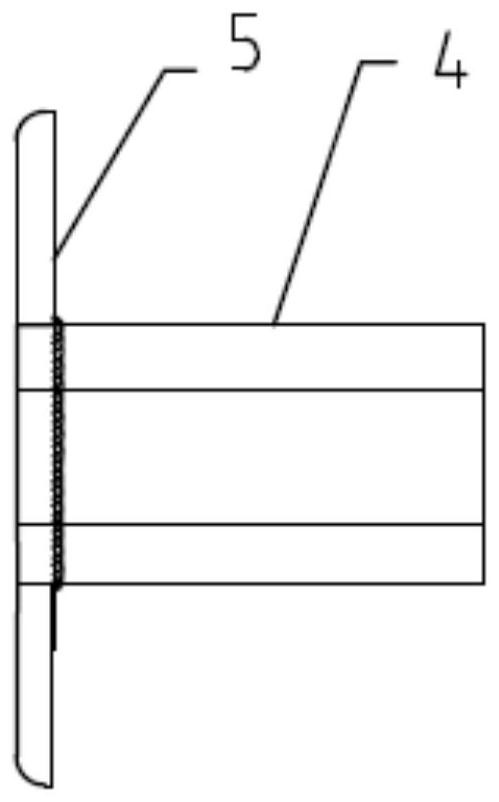

[0039] The screw part 1 includes a screw 2 with an internal thread 2.1, and the outer diameter of the screw 2 is equal to the inner diameter of the thinner end of the special-shaped nut 1;

[0040] The screw part 2 includes a screw 2 3 with an external thread 2 3.1, and one end of the screw 2 3 is screwed to the screw 1 2; ...

Embodiment 2

[0056] combined with Figure 1-7 , other technical solutions remain unchanged, the screw rod two 3 is fixedly connected to the end position of the screw rod three 4 through its end.

[0057] In this embodiment, other technical features remain unchanged, and the second screw 3 is fixedly connected to the third screw 4, thereby achieving the purpose of fixed connection.

[0058] combined with Figure 8, The screw one 2 and the screw three 4 are directly connected to each other through the ends, so as to achieve the purpose of convenient construction.

Embodiment 3

[0060] combined with Figure 9 , under the condition that other technical schemes remain unchanged, the screw rod three 4 and the screw rod two 3 are fixedly connected directly through the ends, so as to achieve the purpose of mutual connection, and the construction is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com