A kind of flexible tooling and using method thereof

A technology of flexible tooling and suits, which is applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve problems such as increased calibration and measurement costs, inability to achieve real-time correspondence, and reduced accuracy of measurement results, so as to eliminate measurement costs and improve The effect of correcting efficiency and processing quality and achieving single-body positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with embodiment.

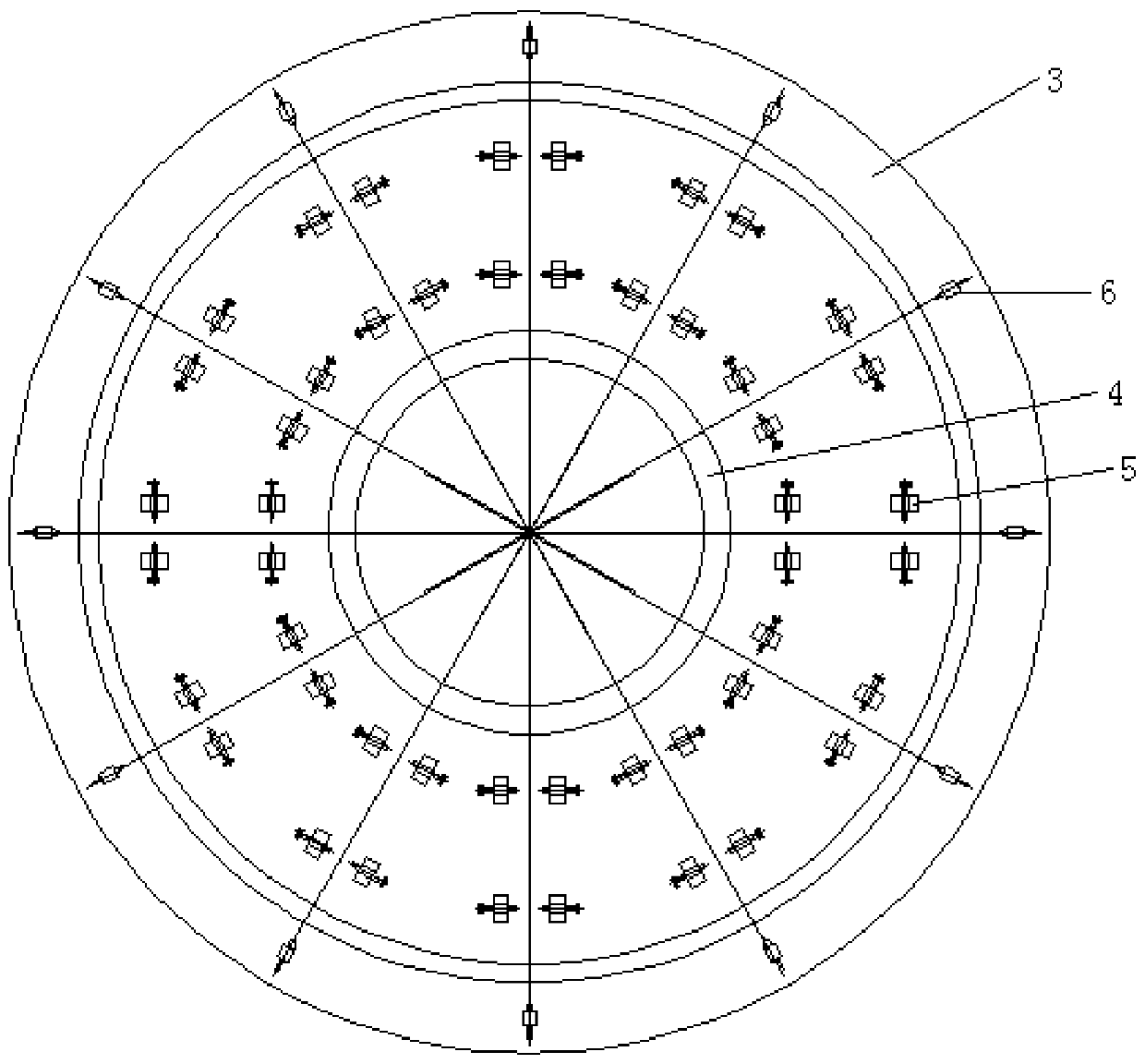

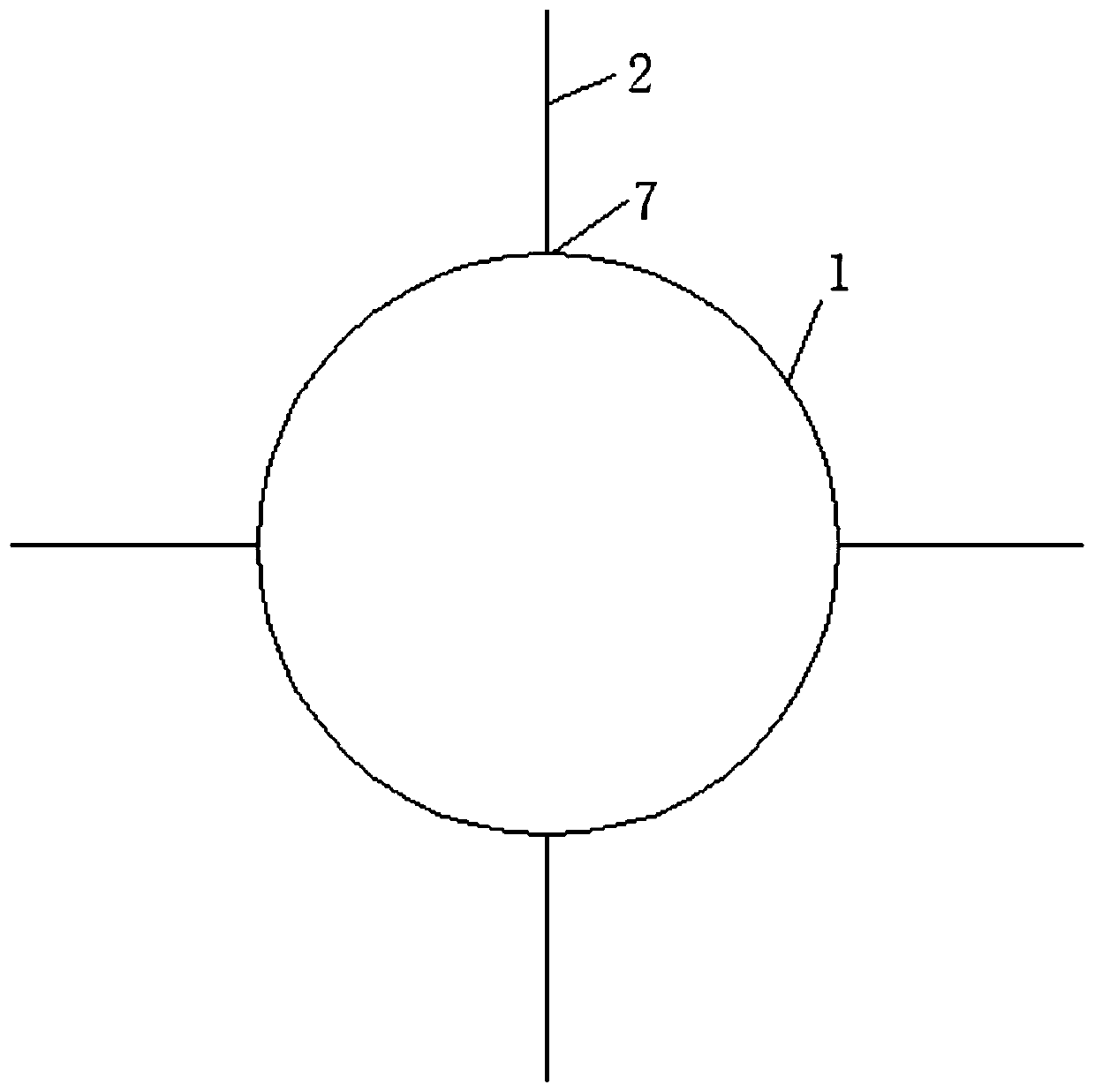

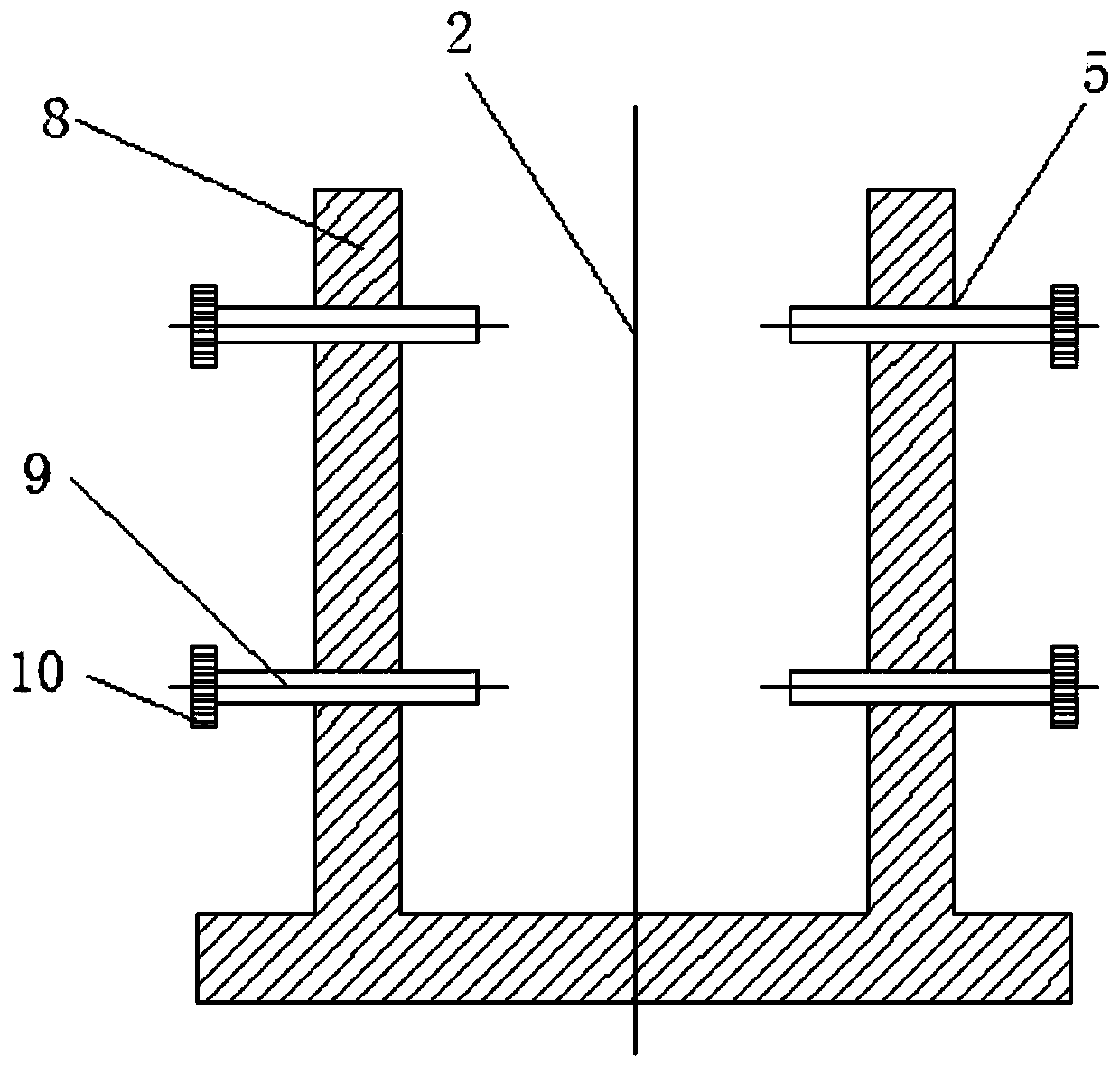

[0028] according to figure 1 As shown, a flexible tooling provided by the present invention is used for clamping parts casing, according to figure 2 As shown, the part casing includes a cylindrical structure 1, and a plurality of support plates 2 are distributed along the circumferential direction on the outer wall of the cylindrical structure 1, and the junction of the support plates and the cylindrical structure is a weld 7 , the tooling includes: a circular bottom plate 3, an annular boss 4 is arranged on the circular bottom plate 3, such as Figure 4 As shown, the cylindrical structure 1 is set on the annular boss 4 for positioning, and a plurality of sets of clamping mechanisms 5 are arranged on the circular bottom plate 3 along the circumference, and the clamping mechanisms 5 support the support plate 2. Carry out clamping and positioning to realize the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com