Sorting control system and method

A technology of control system and servo control system, which is applied in the field of sorting equipment, can solve the problems of lack of mid-section sorting flow rate and difficulty in meeting the production needs of medium-sized enterprises, and achieve the effect of simple structure, meeting enterprise requirements, and filling market vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

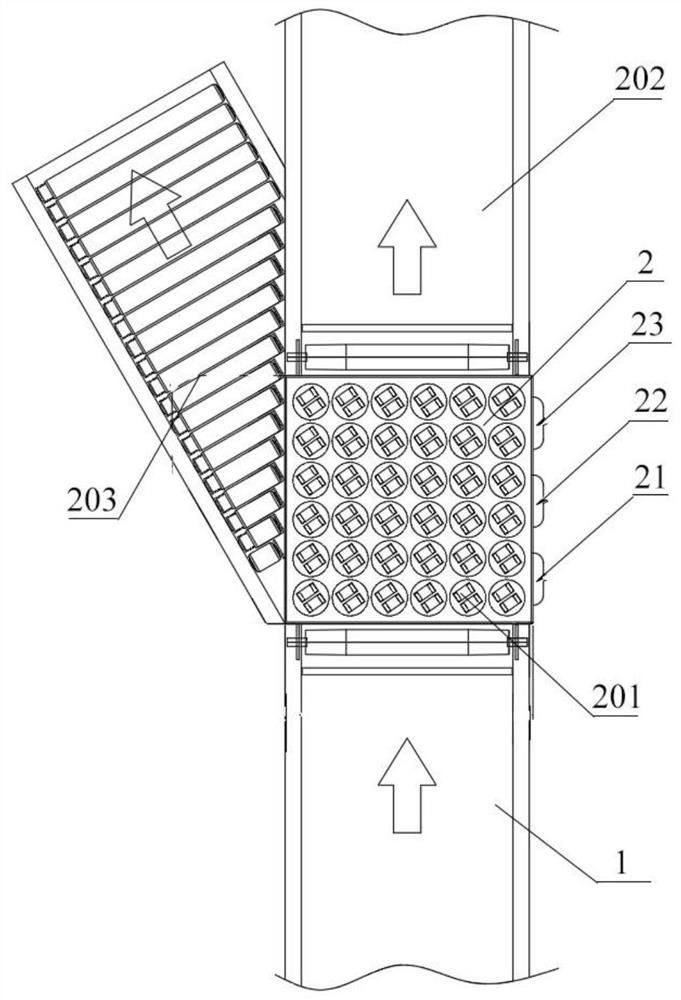

[0026]The sorting control system and method proposed by the present invention will be described in further detail below with reference to the drawings and specific embodiments. According to the following description, the advantages and features of the present invention will be clearer. It should be noted that the drawings are in a very simplified form and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

[0027]As mentioned in the background art, there are currently two sorting equipment with a sorting flow rate on the market, namely a small sorting flow rate equipment of 2000-4000 boxes / hour and a large sorting flow rate equipment of 10000-12000 boxes / hour, but The sorting equipment lacking the sorting flow rate of 6000-8000 boxes / hour, in order to fill the gap in the market and meet the market demand of medium-sized enterprises, this embodiment provides a sorting control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com