A contact bolt production and processing equipment

A technology for processing equipment and contact bolts, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as incomplete separation between the riveting machine and contact bolts, retention of contact bolts, and affecting the normal use of the riveting machine. Improve the quality of sales, prevent virtual connections, and achieve the effect of automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The application will be described in further detail below in conjunction with the accompanying drawings.

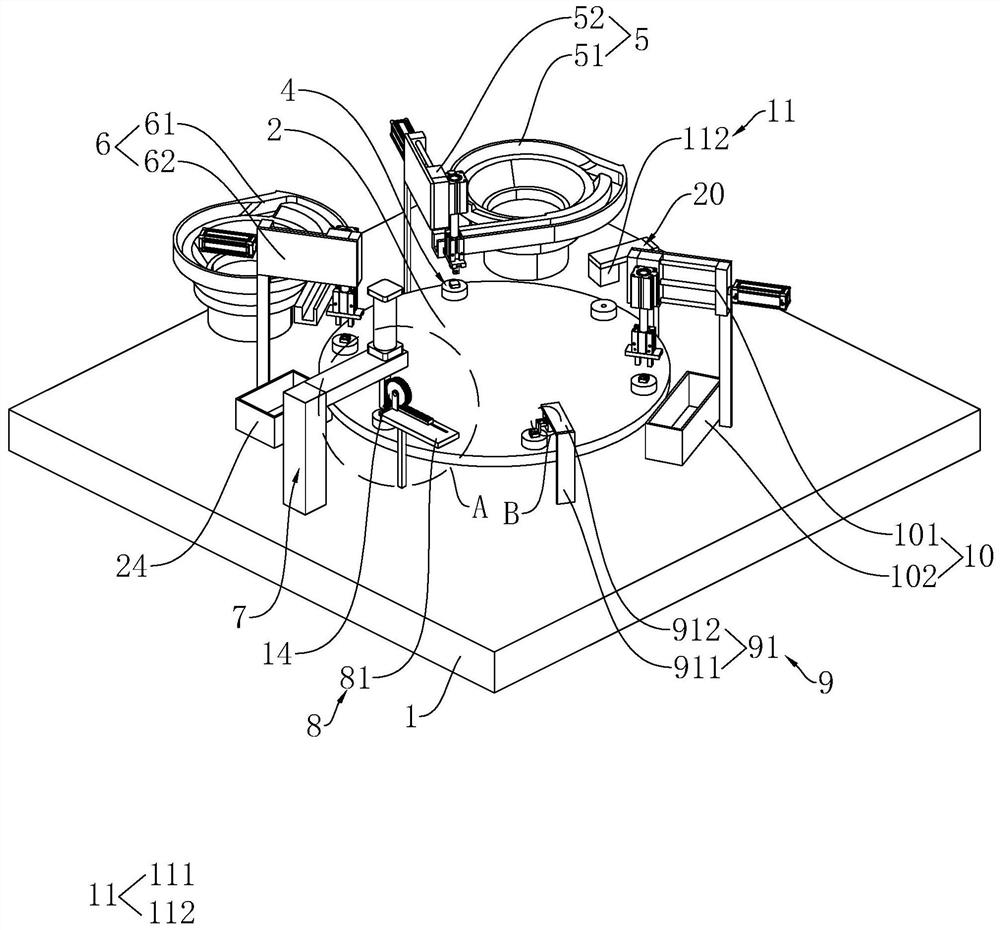

[0041] The embodiment of the present application discloses a contact bolt production and processing equipment. refer to figure 1 The contact bolt production and processing equipment includes a workbench 1 and an intermittent conveying turntable 2 fixedly connected to the upper end surface of the workbench 1 . At the same time, several clamps 4 are fixedly connected to the upper end surface of the conveying turntable 2 .

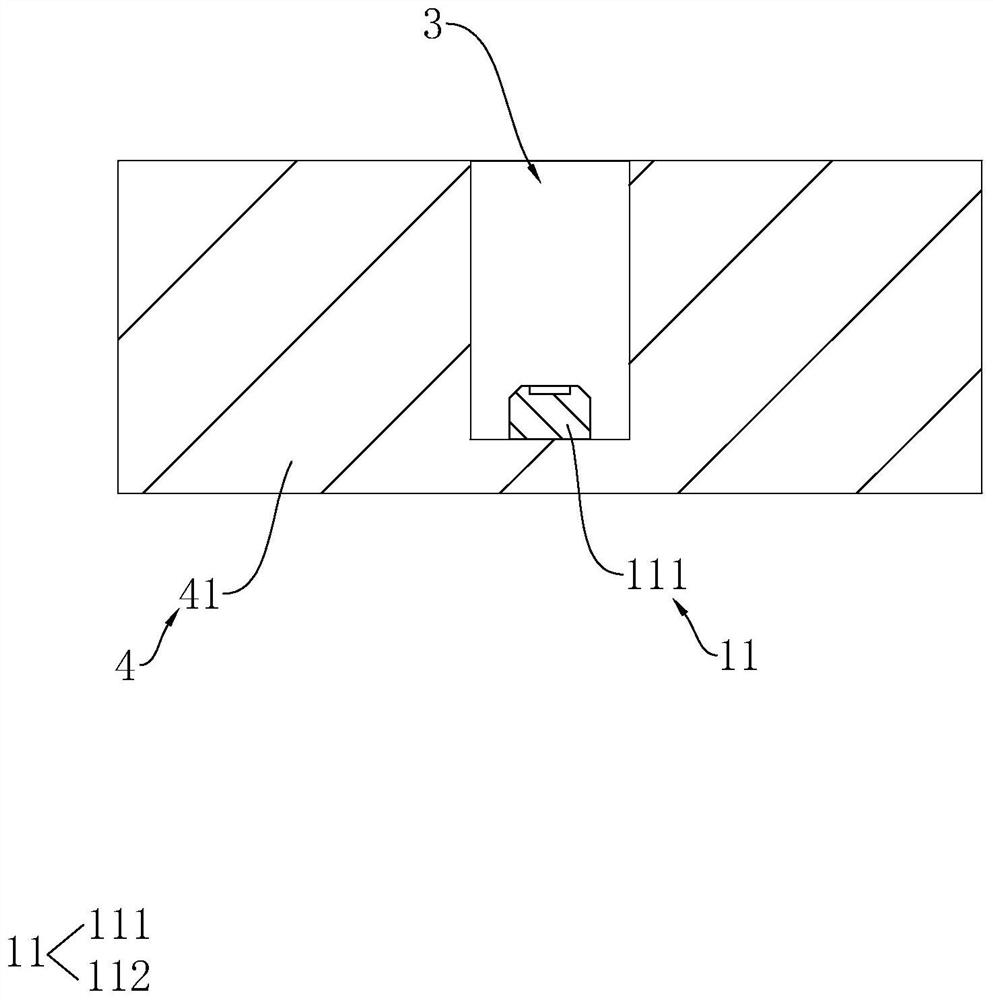

[0042] refer to figure 1 and figure 2 , several clamps 4 are evenly distributed along the circumferential direction of the conveying turntable 2 . The fixture 4 includes a positioning block 41 fixedly connected to the upper end surface of the conveying carousel 2 , and the upper end surface of the positioning block 41 is provided with a positioning groove 3 for insertion and insertion of a screw rod of a bolt.

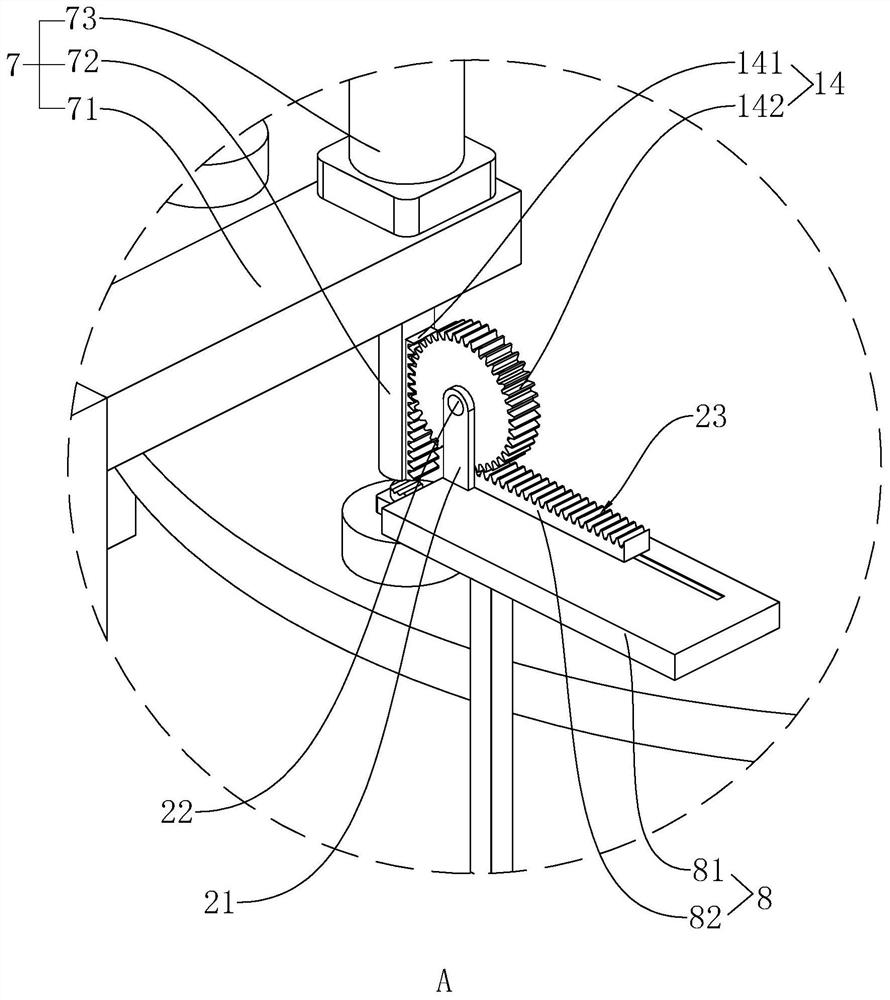

[0043] refer to figure 1 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com