Material supplying mechanism

A material and discharge board technology, applied in the field of packaging, can solve the problems of safety, sanitation and accuracy, congestion, error-prone, etc., and achieve the effect of improving the efficiency of sorting, distribution and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

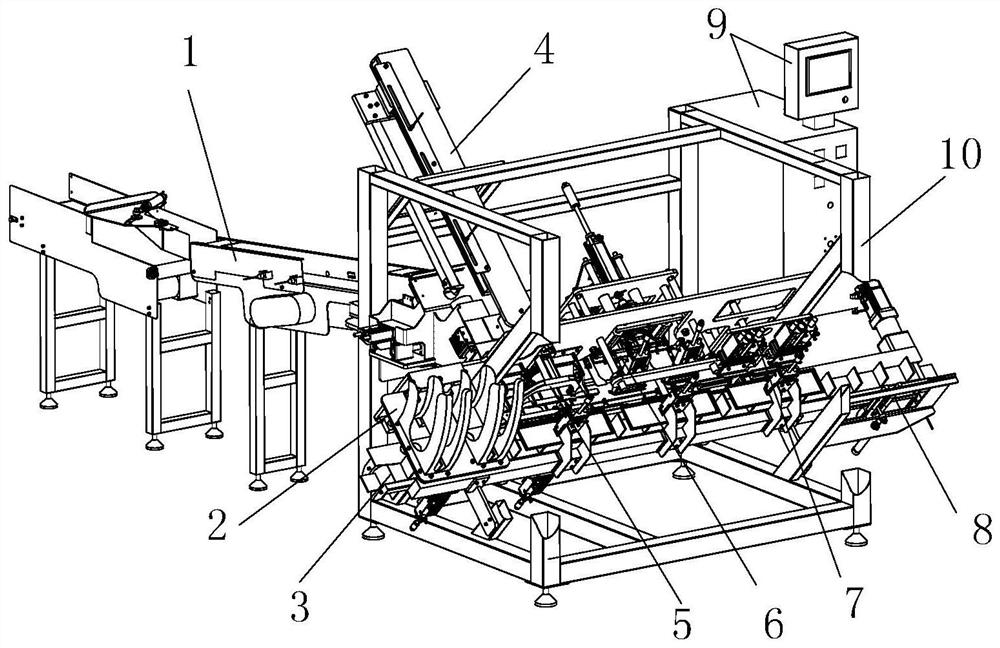

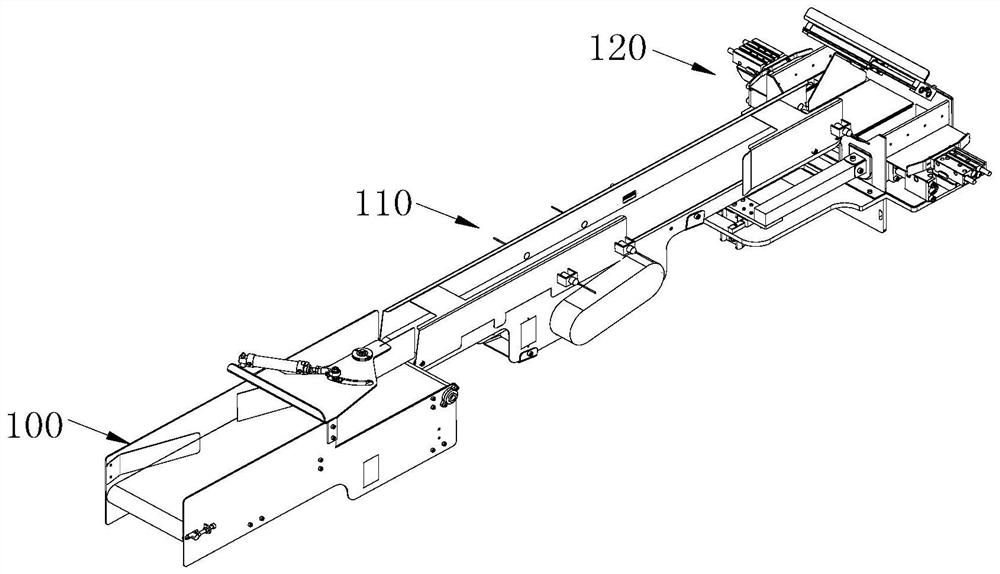

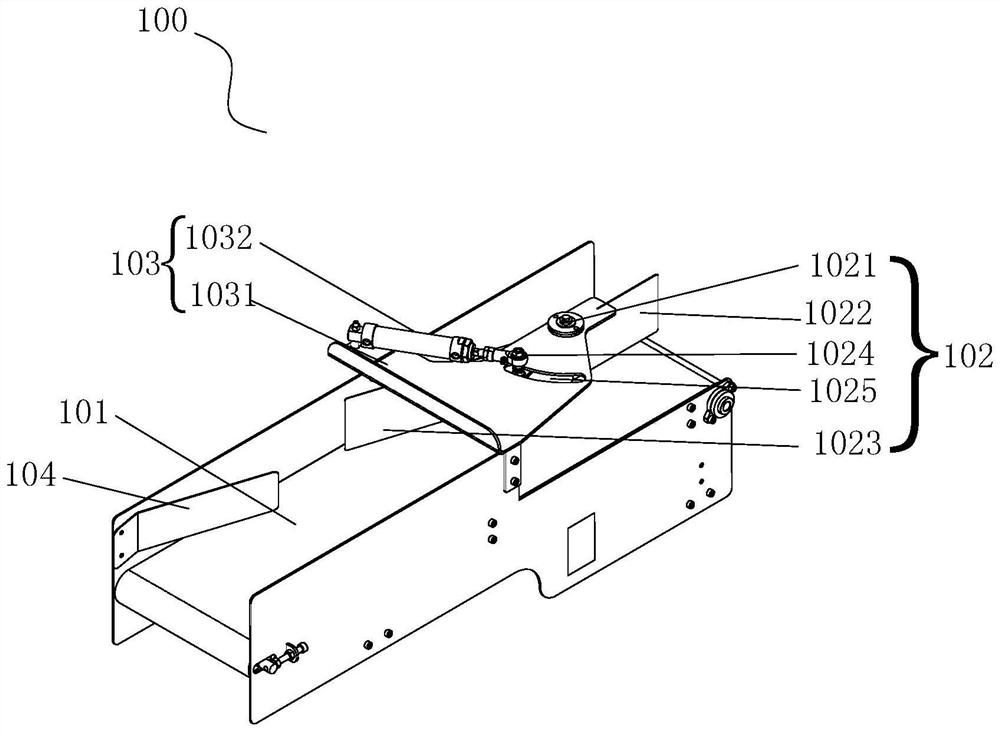

[0099] Such as Figure 1-32 As shown, the whole system of the present invention includes a total support frame 10 and a material supply mechanism 1 fixed on the total support frame 10 to supply materials to be packaged;

[0100] The packaging bag supply mechanism 2 is used to realize the supply function of the packaging bag;

[0101] The bag transport mechanism 3 moves the packaging bag at different stations;

[0102] The material transmission mechanism 4 is used to transmit the material falling from the material supply mechanism and push the material into the packaging bag;

[0103] The bag opening and filling mechanism 5 is used to open the packaging bag and put materials into it;

[0104] Shaping mechanism 6, shaping the mouth of the packaging bag to prepare for sealing;

[0105] The sealing mechanism 7 is used for sealing the packaging bag;

[0106] The finished product output mechanism 8 is used to output the finished product to the next process.

[0107] The control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com