A kind of environment-friendly synchronous decorative paper and its printing process

A decorative paper, an environmentally friendly technology, applied in the field of decorative paper printing, can solve the problems of deviation of the texture and embossing of the wood-based panel, the appearance quality of the decorative paper is degraded, and the lack of solid wood stereoscopic effect, etc., to achieve the effect of strong realistic stereoscopic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

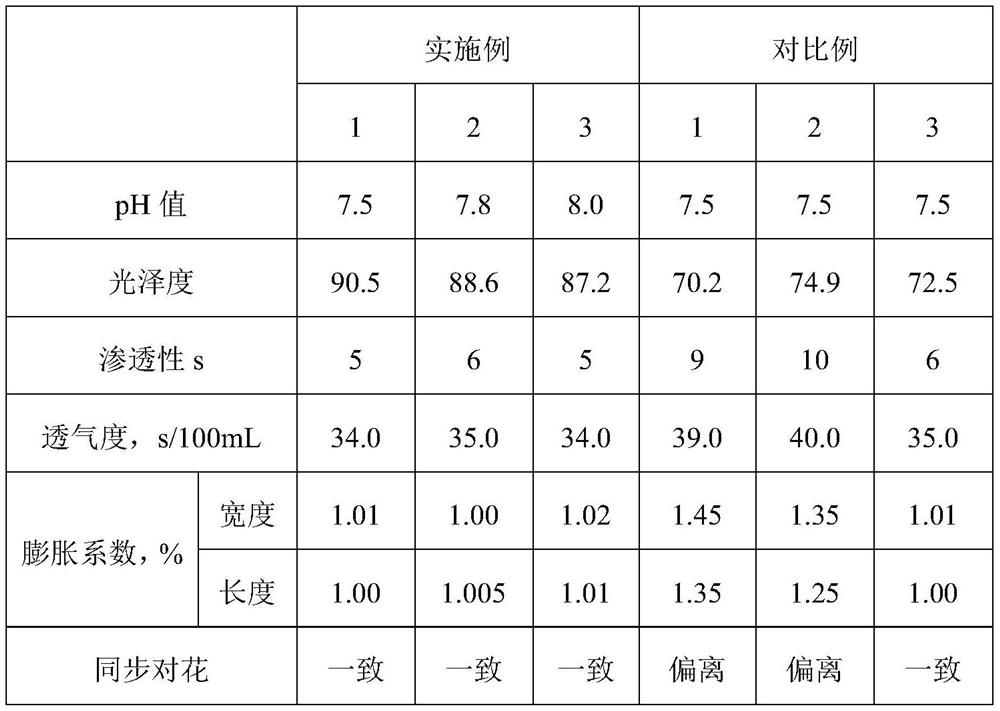

Embodiment 1

[0029] The printing process of the environment-friendly synchronous decorative paper of the present embodiment comprises the following steps:

[0030] (1) material selection

[0031] Decorative base paper: choose the decorative base paper with expansion coefficient: width 2.15-2.30%, length 1.75-2.05%.

[0032] Environmentally friendly water-based ink: water-based ink with a viscosity of 20s, a fineness of ≤5 μm, and a pH of 7.5.

[0033] Wherein, the environment-friendly water-based ink of the present embodiment includes the following components by weight:

[0034] 60 parts of water-soluble acrylic resin, 15 parts of color paste, 1 part of titanium dioxide, 2 parts of sulfated castor oil, 1 part of shea butter, 0.5 part of leveling agent, and 0.5 part of defoamer.

[0035] A specific modulation method includes the following steps:

[0036] First mix the water-soluble acrylic resin and color paste, then add the mixture of titanium dioxide and sulfated castor oil, then add s...

Embodiment 2

[0042] The printing process of the environment-friendly synchronous decorative paper of the present embodiment comprises the following steps:

[0043] (1) material selection

[0044] Decorative base paper: choose the decorative base paper with expansion coefficient: width 2.45-2.65%, length 2.85-3.05%.

[0045] Environmentally friendly water-based ink: water-based ink with a viscosity of 16s, a fineness of ≤5 μm, and a pH of 7.8.

[0046] Wherein, the environment-friendly water-based ink of the present embodiment includes the following components by weight:

[0047] 50 parts of water-soluble acrylic resin, 20 parts of color paste, 2 parts of titanium dioxide, 1.5 parts of sulfated castor oil, 0.8 parts of shea butter, 0.3 parts of leveling agent, and 0.3 parts of defoamer.

[0048] A specific modulation method includes the following steps:

[0049] First mix the water-soluble acrylic resin and color paste, then add the mixture of titanium dioxide and sulfated castor oil, th...

Embodiment 3

[0055] The printing process of the decorative paper of the present embodiment comprises the following steps:

[0056] (1) material selection

[0057] Decorative base paper: choose the decorative base paper with expansion coefficient: width 2.65-2.75%, length 3.55-3.75%.

[0058] Environmentally friendly water-based ink: water-based ink with a viscosity of 26s, a fineness of ≤5μm, and a pH of 8.0. .

[0059] Wherein, the water-based ink of the present embodiment includes the following components by weight:

[0060] 70 parts of water-soluble acrylic resin, 25 parts of color paste, 3 parts of titanium dioxide, 2 parts of sulfated castor oil, 0.5 part of shea butter, 0.6 part of leveling agent, and 0.6 part of defoamer.

[0061] A specific modulation method includes the following steps:

[0062]First mix the water-soluble acrylic resin and color paste, then add the mixture of titanium dioxide and sulfated castor oil, then add shea butter, leveling agent and defoamer, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com