Method for preparing sintered neodymium iron boron device

A neodymium-iron-boron and device technology is applied in the field of preparation of sintered neodymium-iron-boron devices, which can solve the problems of scrapping defective products, waste of raw materials, and increased costs, and achieve the effects of reducing raw material loss, saving raw materials, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

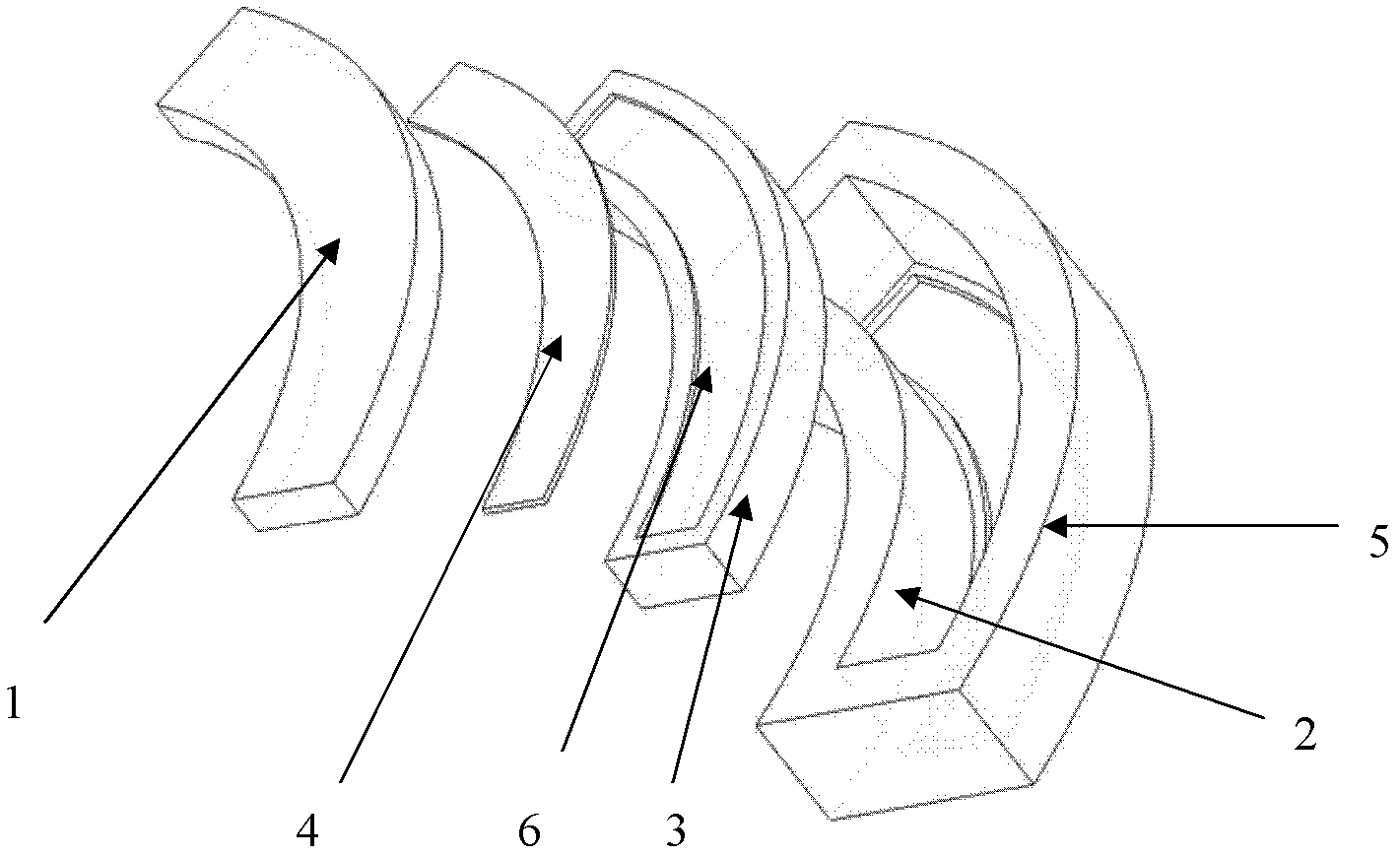

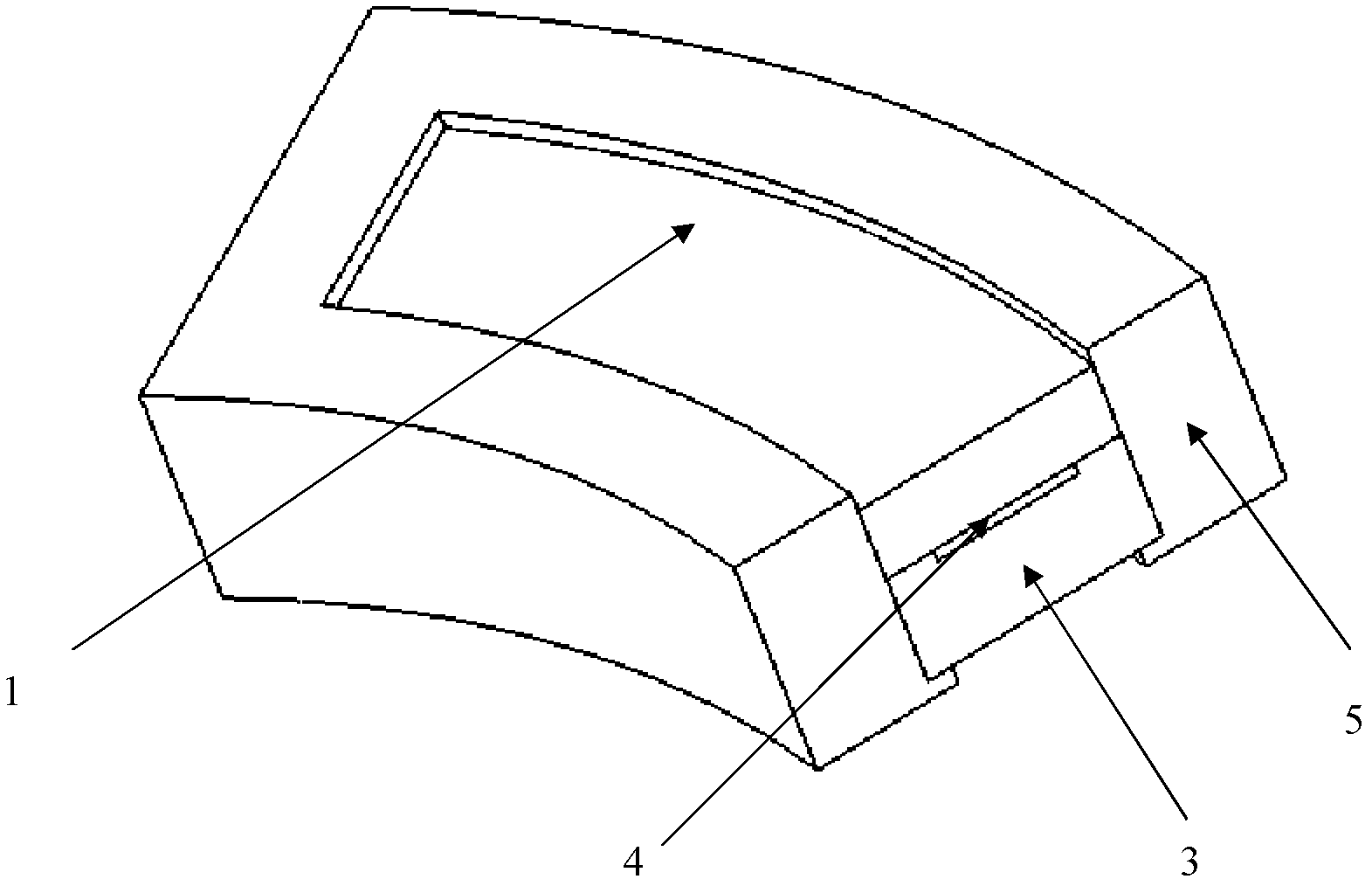

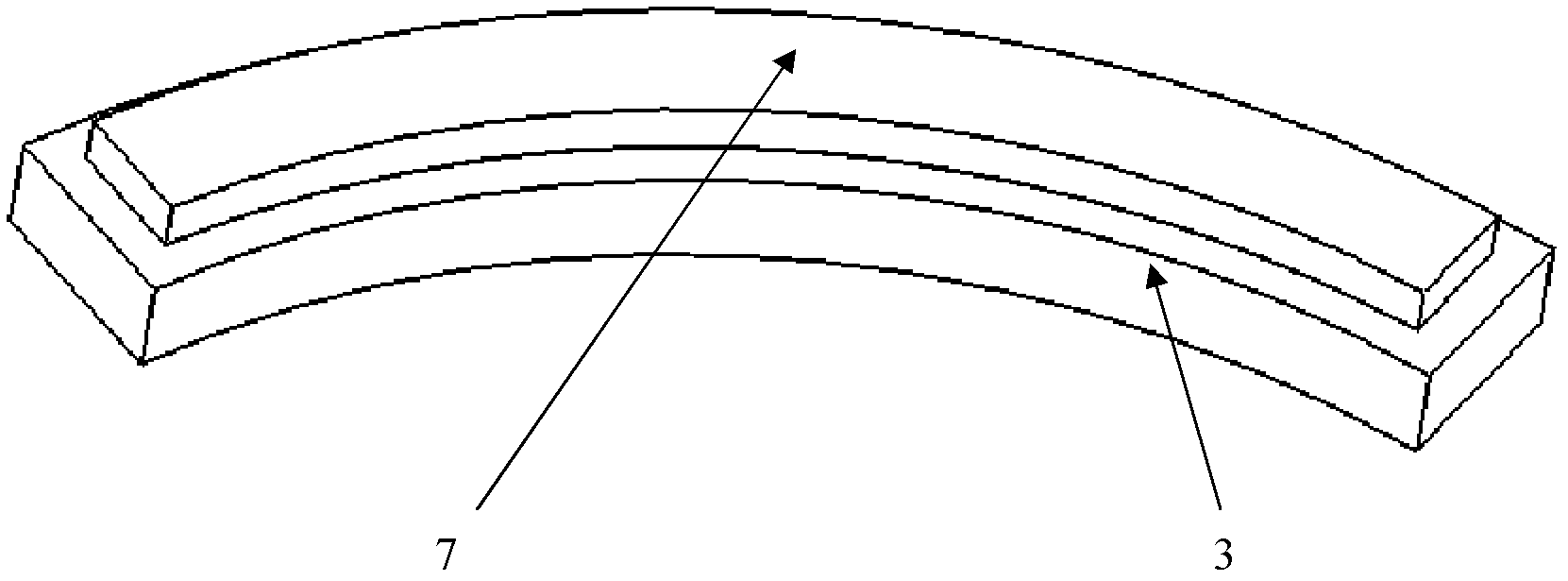

[0028] Embodiment one: if figure 1 Shown, a kind of preparation method of sintered NdFeB device, take a substrate 3 that is suitable for sintered NdFeB device, open a groove 6 on the upper surface of substrate 3; The depth of groove 6 is 0.05mm, will A nickel alloy foil 4 with a thickness of 0.05 mm is inserted into the groove 6 of the base 3; a surrounding frame 5 with a cavity 2 matching the shape of the base 3 is made, and the groove 6 of the base 3 is placed upwards At the bottom of the cavity 2, a material tray composed of a matrix 3 and a frame 5 is obtained; the NdFeB fine powder 1 is filled in the cavity 2 and the NdFeB fine powder 1 is compacted, and the specific structure is as follows figure 2 As shown; the tray filled with NdFeB fine powder 1 is moved into the electromagnetic field generating device to orient the NdFeB fine powder 1; the tray after orientation treatment is placed in the sintering pot, and then the sintering pot is moved into the sintering furnace ...

Embodiment 2

[0030] Embodiment 2: A preparation method of sintered NdFeB devices is basically the same as Embodiment 1, the only difference is

[0031] The depth of the groove 6 is 0.30mm, and the thickness of the corresponding nickel alloy foil 4 is also 0.30mm.

Embodiment 3

[0032] Embodiment 3: A preparation method of sintered NdFeB devices, which is basically the same as Embodiment 1, the only difference is

[0033] The depth of the groove 6 is 0.30 mm, and the thickness of the corresponding nickel alloy foil 4 is 0.20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com