Multi-stage swing system for quickly connecting prefabricated assembled pier and bearing platform

A rocking system, prefabricated and assembled technology, applied in the field of multi-level rocking systems, can solve the problems of time-consuming wet-joint and grouting forming strength, unable to check the anchoring situation, etc., to achieve great convenience and time benefit, excellent deformation ability, The effect of increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] This embodiment provides a multi-stage rocking system that can function in both the longitudinal and transverse directions at the same time.

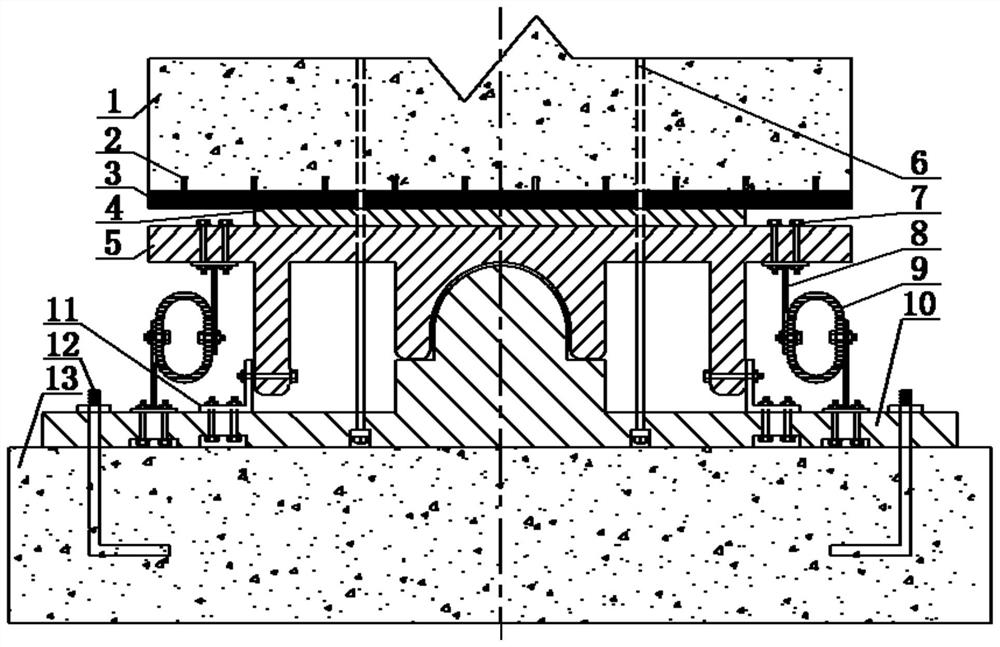

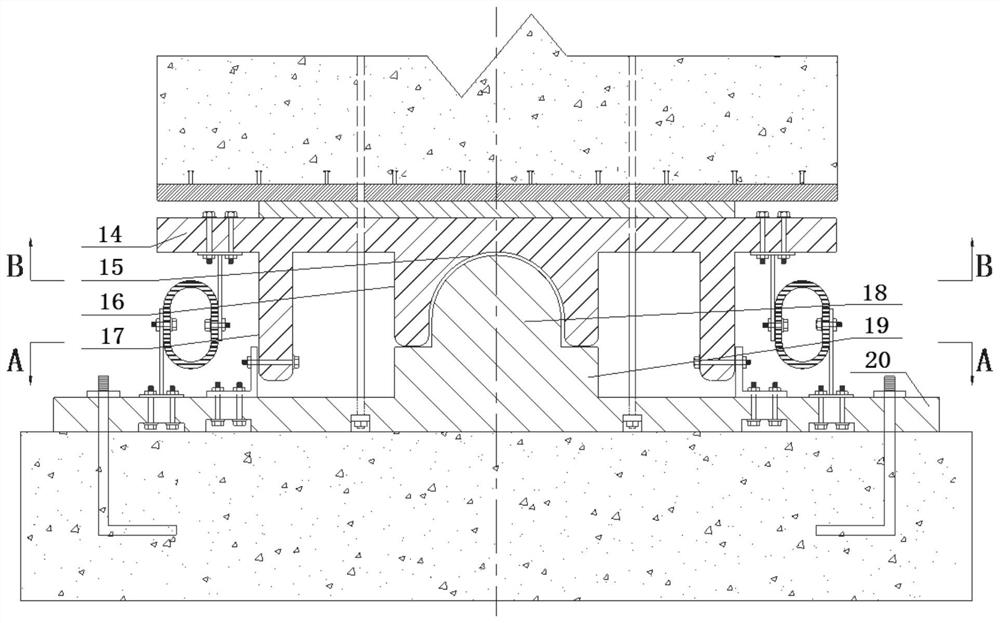

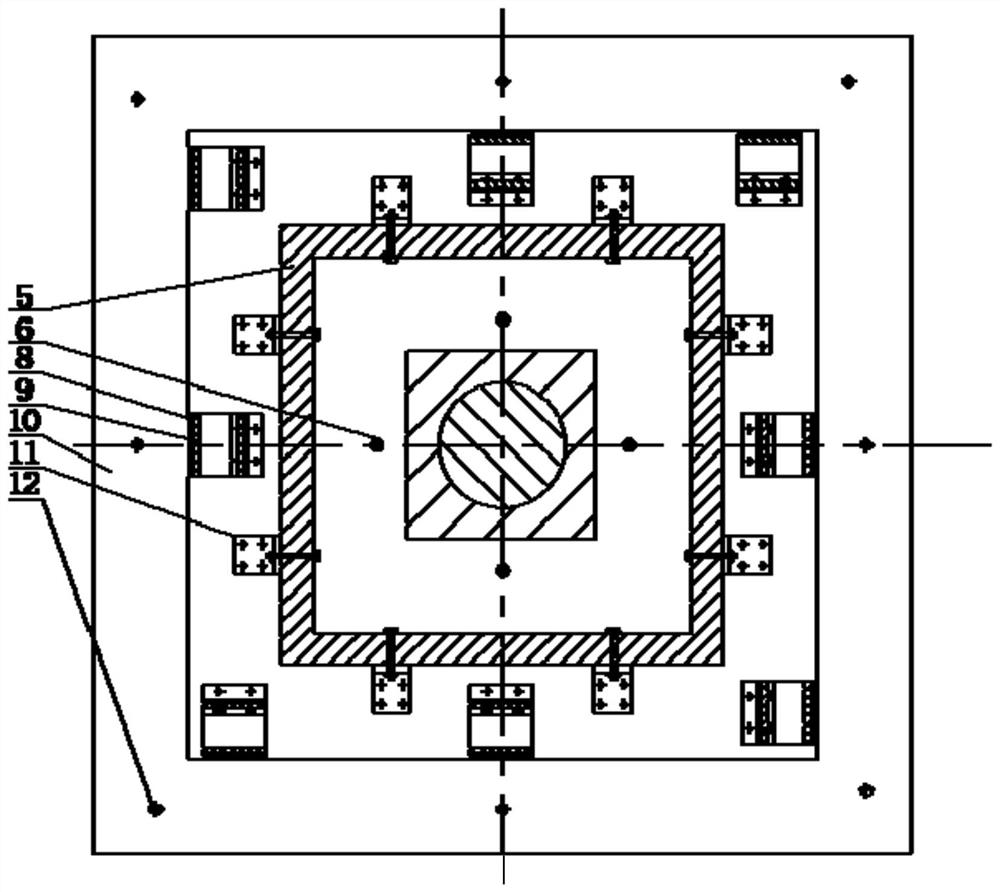

[0045] Such as Figure 1 to Figure 9 As shown, this embodiment provides a multi-stage swing system for quick connection between prefabricated assembled bridge piers and caps. 9, the lower wall 10 and the limit angle steel 11. In this multi-stage rocking system, the bottom sealing plate 3 is anchored to the bottom of the pier column 1; the bottom sealing plate 3 and the upper plate 5 are directly welded, or a steel backing plate 4 is set between the bottom sealing plate 3 and the upper plate 5, and the steel backing plate 4 The plate 4 is welded to the bottom sealing plate 3 and the upper plate 5; a U-shaped energy dissipator 9 is arranged between the upper plate 5 and the lower plate 10, and the U-shaped energy dissipator 9 is connected to the upper plate 5 and the lower plate 10 through bolts 7; A limiting angle steel 11 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com