Constant velocity turning joint

A technology of constant velocity universal joints and external joints, which is applied to rotating parts, elastic couplings, and mechanical equipment that resist centrifugal force, and can solve problems such as shortening service life and reducing breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

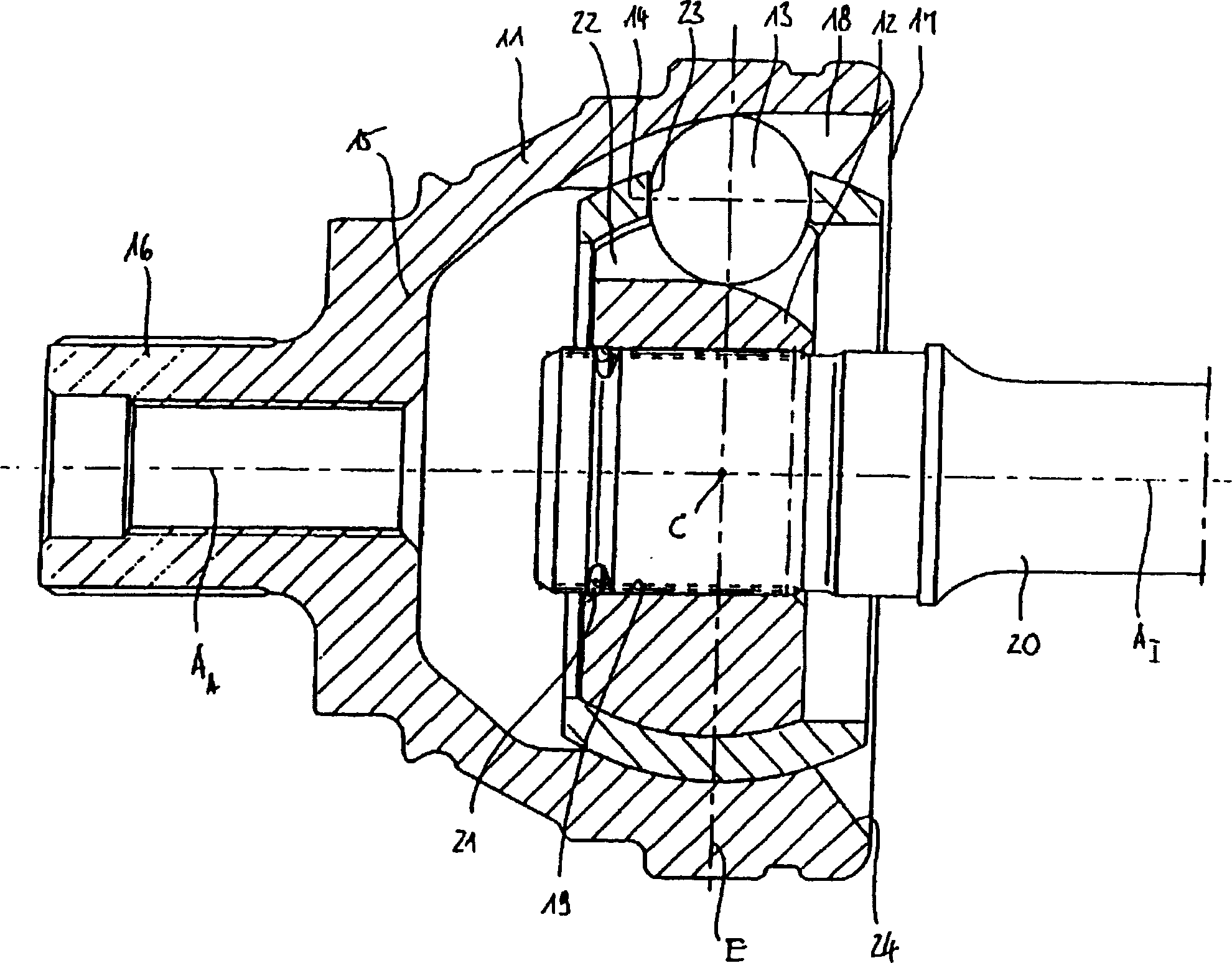

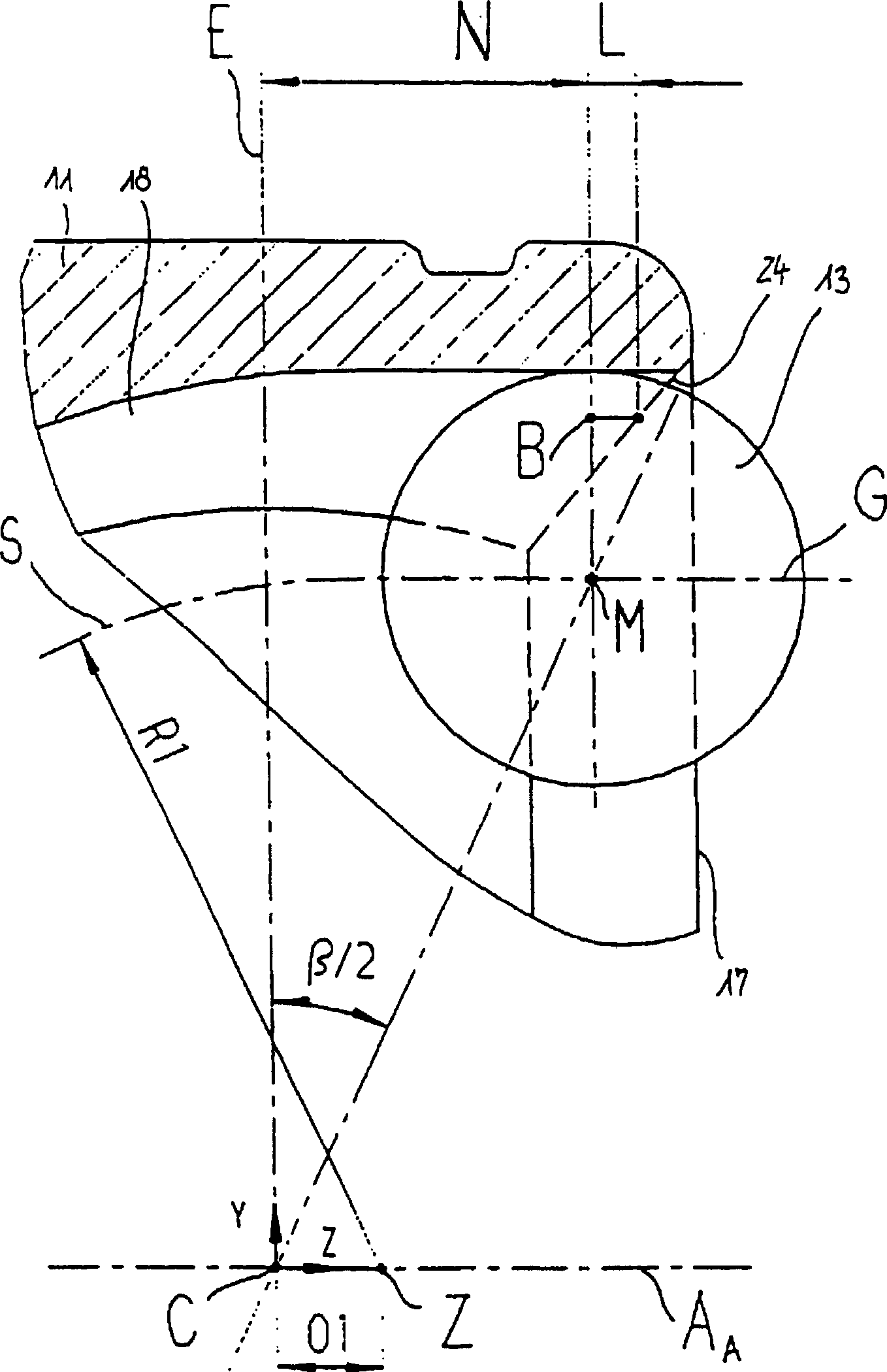

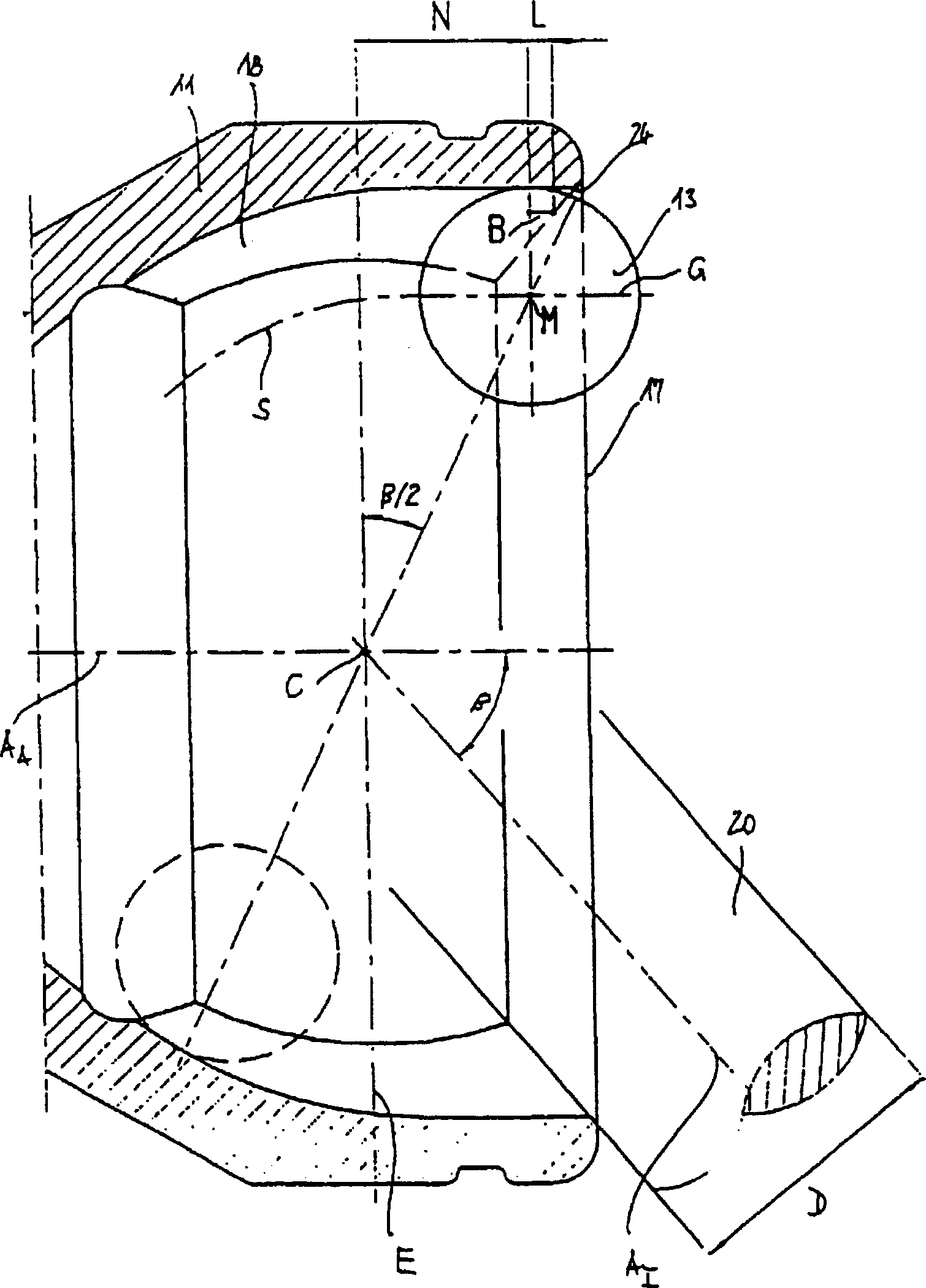

[0019] figure 1 There is shown a prior art constant velocity universal joint comprising an outer joint part 11, an inner joint part 12, torque transmitting balls 13 and a ball spacer 14. At one end, the outer joint part 11 is closed off by a bottom 15 followed by a joint journal 16 . Opposite the bottom 15 in the axial direction is a bore 17 of the outer joint part 11 . In the outer joint part 11, one of a plurality of outer ball tracks 18 distributed along the outer circumference is shown, as viewed from the open end 17, this track is not undercut. The inner joint part 12 is provided with a central hole 19 through which a connecting shaft 20 fixed axially by a positioning ring 21 is inserted. In this inner joint part 12, one of a plurality of outer ball tracks 22 distributed along the outer circumference is shown, which track is also free of undercuts as seen from the open end 17. The outer ball track 18 and the inner ball track 22 are associated with each other as a pair ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap