V-shaped ball valve with valve element suitable for large-temperature-difference flow system

A technology with large temperature difference and valve core, applied in pipeline system, valve details, valve device and other directions, can solve the problems of poor application effect and improve adjustment accuracy, and achieve the effect of large adjustable angle and accurate flow adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

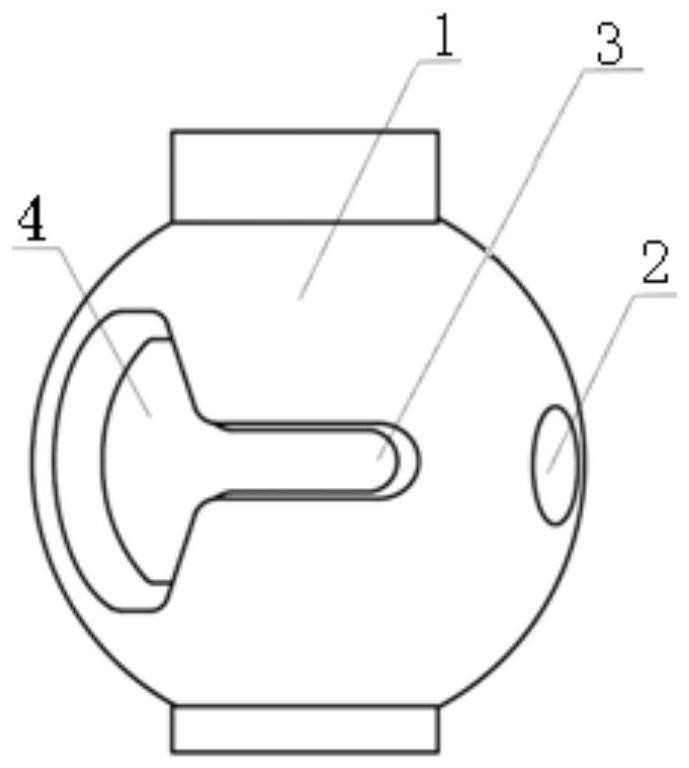

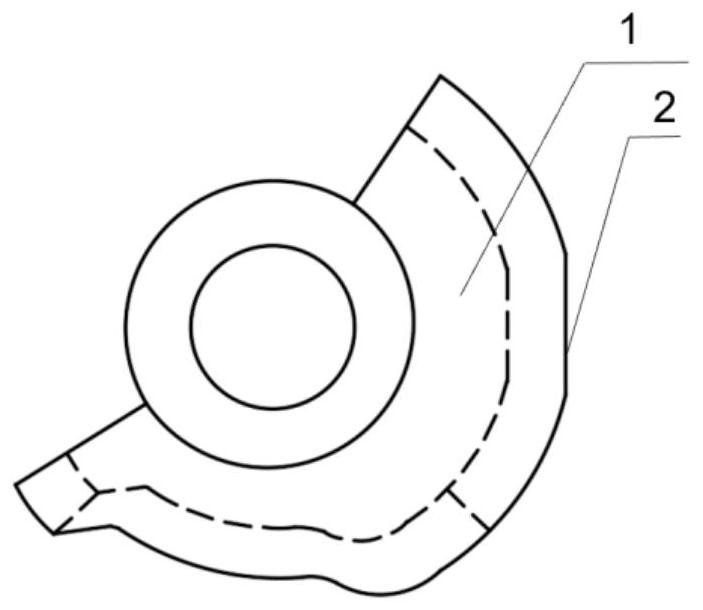

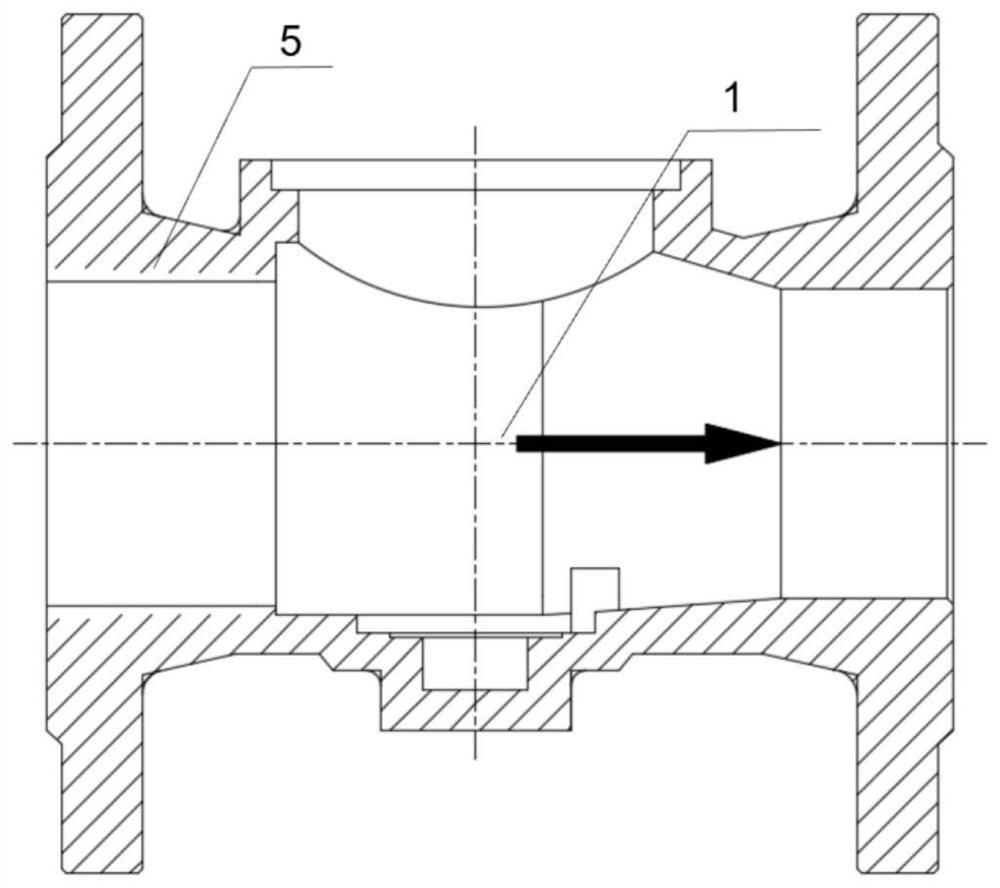

[0018] The design concept of the present invention is that for the heating pipe network and similar large temperature difference flow systems, the flow requirements of each branch are relatively small, so the requirements for valves to adjust small flow are relatively high. Due to the different spatial positions of the pipeline layout, the pressure difference between different pipe network branches varies greatly. The ball valve designed in the present invention provides a multi-opening precision ball valve by changing the structure of the valve hole on the traditional V-shaped ball valve core. The V-shaped ball valve for adjusting the flow rate can achieve the purpose of high-precision small flow adjustment and the ideal equal-percentage performance curve by changing the shape of the ball valve spool, thereby improving the adjustment sensitivity of the branch with a large pressure difference.

[0019] The present invention will be further described below in conjunction with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com