A system and method for on-line detection of train faults

A detection system and technology for faults, applied in radio wave measurement systems, satellite radio beacon positioning systems, railway vehicle testing, etc., can solve the problems of manual investigation, which cannot be checked in real time around the clock, long detection cycle of wheel sensors, and inability to alarm in time. Achieve the effect of flexible layout, no detection blind area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

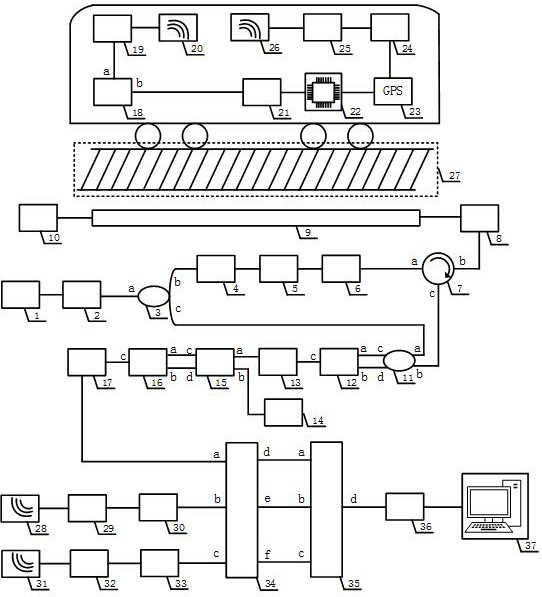

[0021] see figure 1 , the present invention provides an on-line detection system for train faults, including:

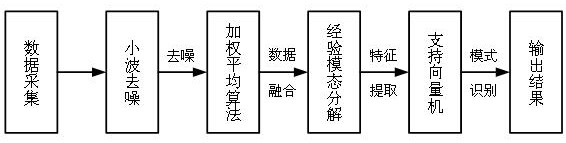

[0022] Narrow linewidth laser 1, first fiber coupler 3, acousto-optic modulator 4, wavelength division multiplexer 6, circulator 7, optical cable connection box 8, optical cable 9, pigtail terminal box 10, second optical fiber coupler 11 , balanced photodetector 12, band-pass filter 13, sine wave generator 14, quadrature demodulator 15, low-pass filter 16, amplitude operator 17, three-axis accelerometer 18, first signal modulator 19 , the first wireless signal generator 20, the high-speed analog-to-digital conversion module 21, the microcontroller 22, the global positioning system 23, the first data converter 24, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com