Aviation airborne heat exchange network optimization method based on superstructure model

A technology of heat exchange network and optimization method, applied in design optimization/simulation, computer-aided design, special data processing application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

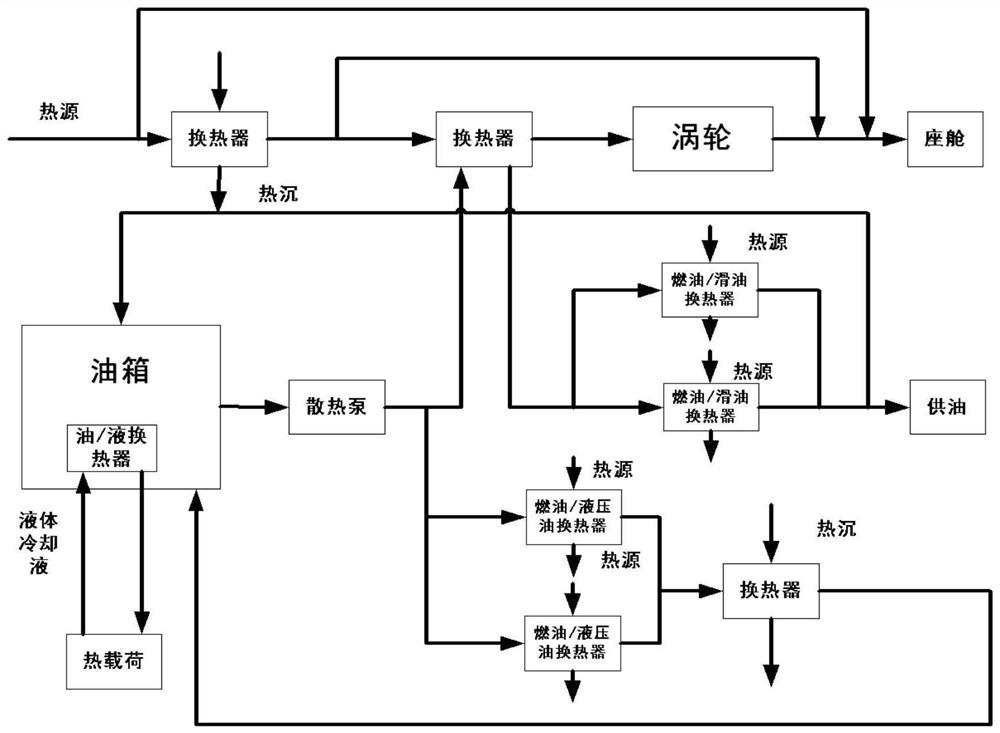

[0020] by figure 1 The shown airborne thermal management system heat exchange network is used as an object, and the method of the present application is further illustrated or described.

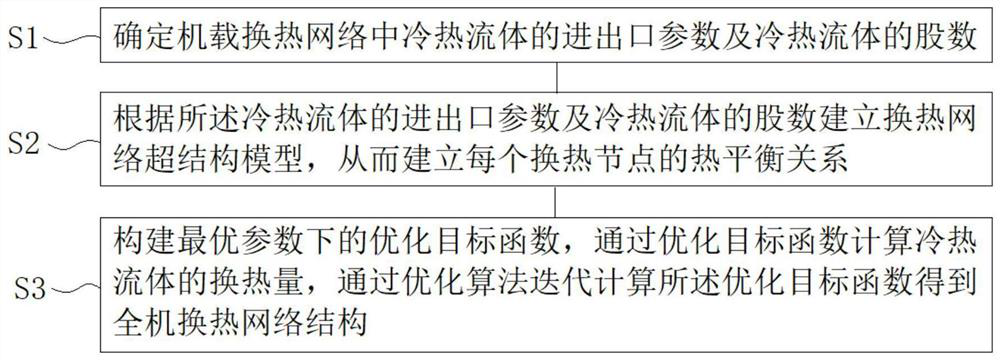

[0021] This method mainly includes the following processes:

[0022] S1. First, according to the actual situation of the onboard heat sink and heat source, the analysis of the number of hot and cold fluids in the thermal management system is completed, and the import and export parameters of the hot and cold fluids in the airborne network and the number of hot and cold fluids are determined.

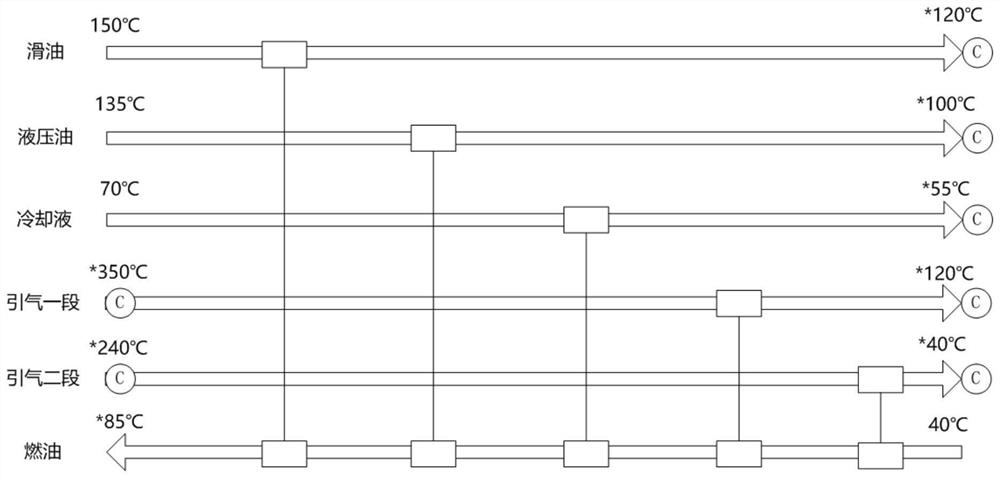

[0023] For example figure 1 A typical airborne thermal management system thermal network shown in , contains five streams of hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com