Water supply method and system for multi-water-source industrial new water

A technology of water supply system and multiple water sources, which is applied in the configuration of water supply devices, water supply devices, and water supply pools, etc., can solve problems such as unreasonable layout, and achieve the effect of solving unreasonable layout, improving enterprise economic benefits, and saving water supply and power supply costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

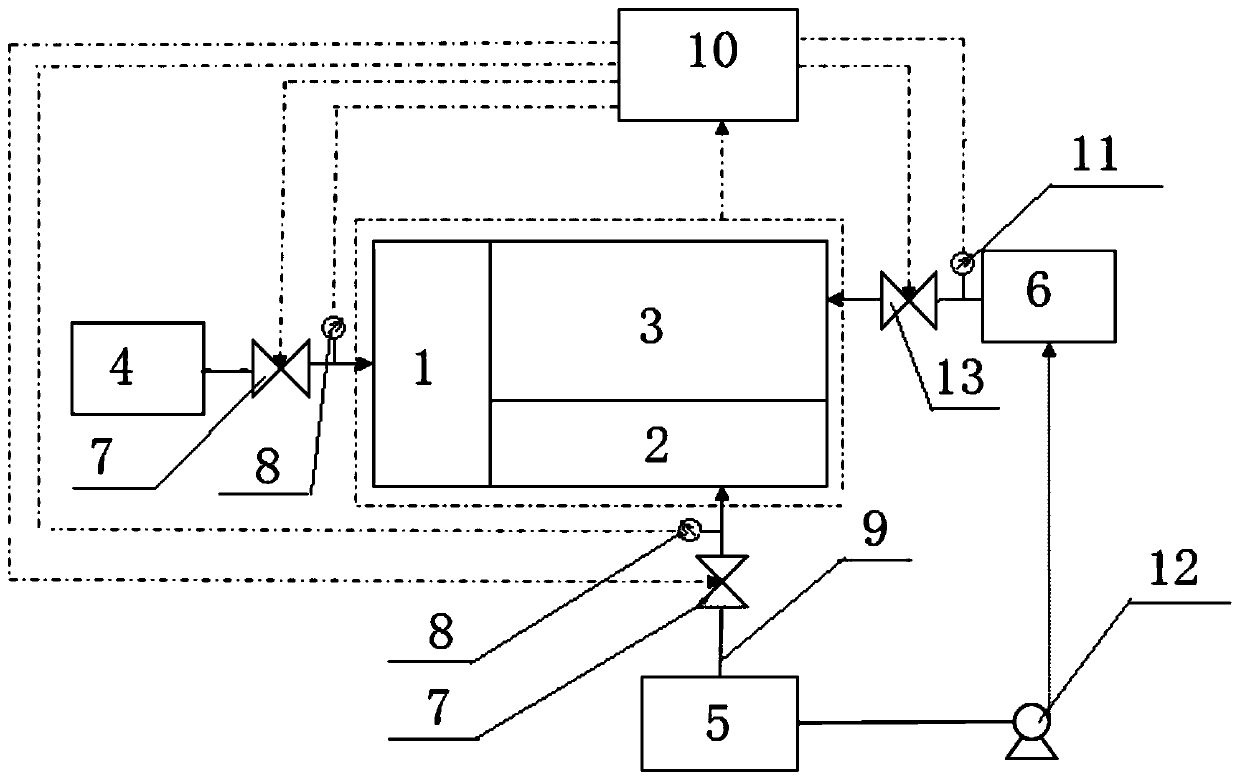

Image

Examples

Embodiment 1

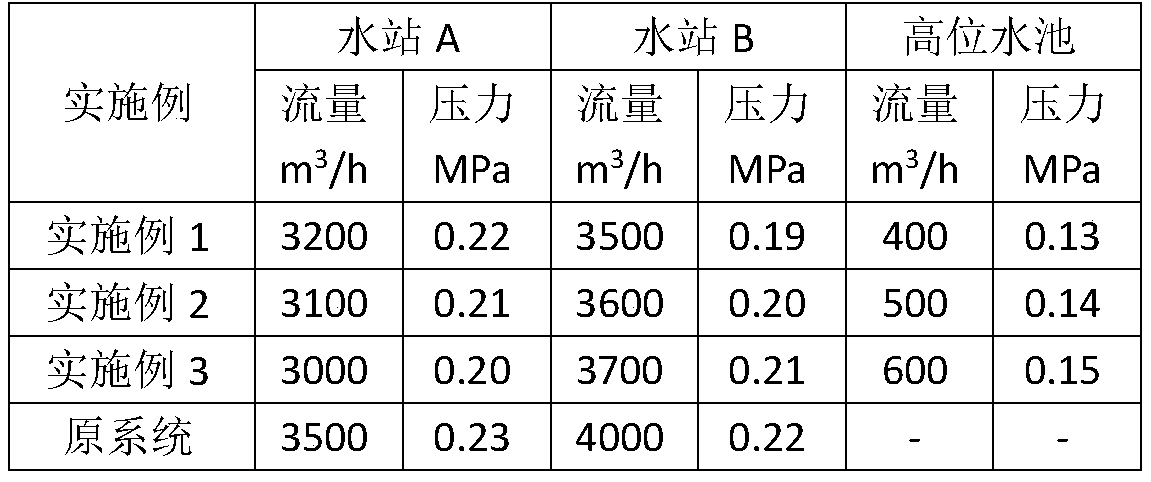

[0039] Under the condition of meeting the most unfavorable point pressure of new water users in each user area, the water supply flow of water station A4 is 3200m 3 / h, the operating pressure is 0.22MPa, the water supply flow of water station B5 is 3500m 3 / h, the operating pressure is 0.19MPa, and the water supply flow rate of the high-level pool 6 is 400m 3 / h, the operating pressure is 0.13MPa.

Embodiment 2

[0041] Under the condition of meeting the most unfavorable point pressure of new water users in each user area, the water supply flow of water station A4 is 3100m 3 / h, the operating pressure is 0.21MPa, the water supply flow of water station B5 is 3600m 3 / h, the operating pressure is 0.20MPa, and the water supply flow rate of the high-level pool 6 is 500m 3 / h, the operating pressure is 0.14MPa.

Embodiment 3

[0043] Under the condition of meeting the most unfavorable point pressure of new water users in each user area, the water supply flow of water station A4 is 3000m 3 / h, the operating pressure is 0.20MPa, the water supply flow of water station B5 is 3700m 3 / h, the operating pressure is 0.21MPa, and the water supply flow rate of the high-level pool 6 is 600m 3 / h, the operating pressure is 0.15MPa.

[0044] The experimental result and contrast of each embodiment of table 1

[0045]

[0046] It can be obtained from Table 1 that the operating pressure of the original water system is greater than 0.22MPa, and the flow rate is 7500m 3 / h, after the present invention introduces the high-level pool, the operating pressure and flow rate of the new water system are reduced, realizing the reduction and depressurization operation of the new water system, which not only reduces the risk of pipe bursting, but also saves water supply and power supply for enterprises The cost has achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com