Ceramic product surface spot detection method and equipment based on machine vision

A technology of surface spots and detection methods, applied in the field of image processing, can solve the problems of high difficulty and high cost of surface spot detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

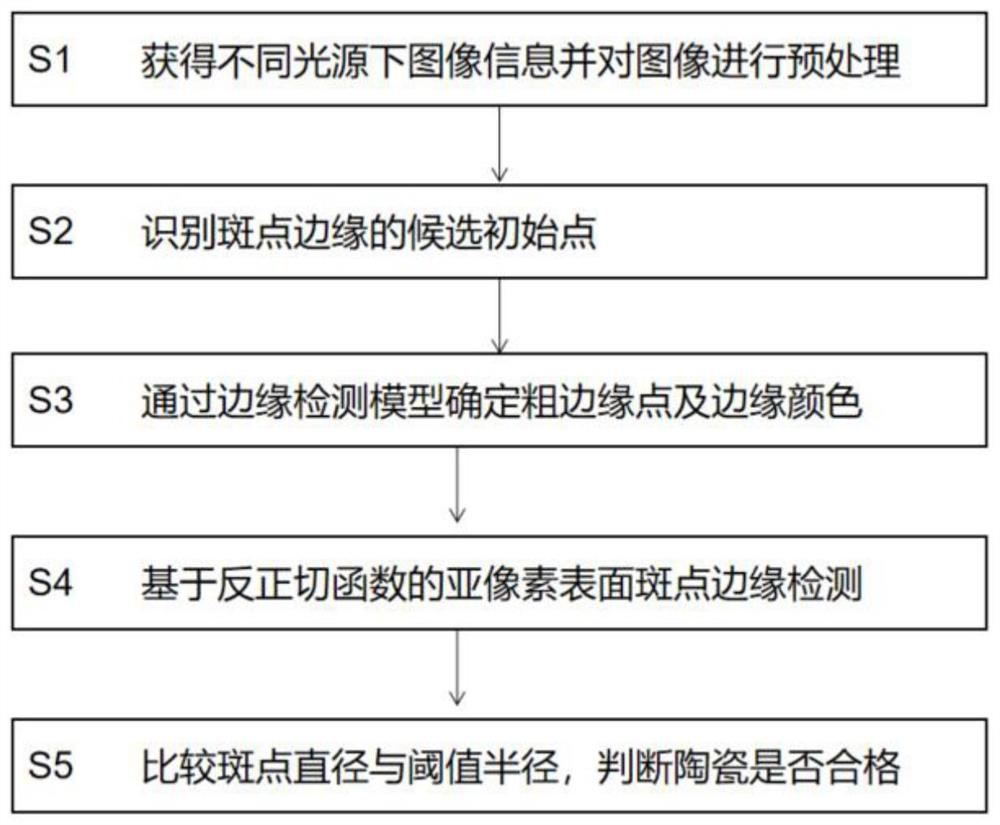

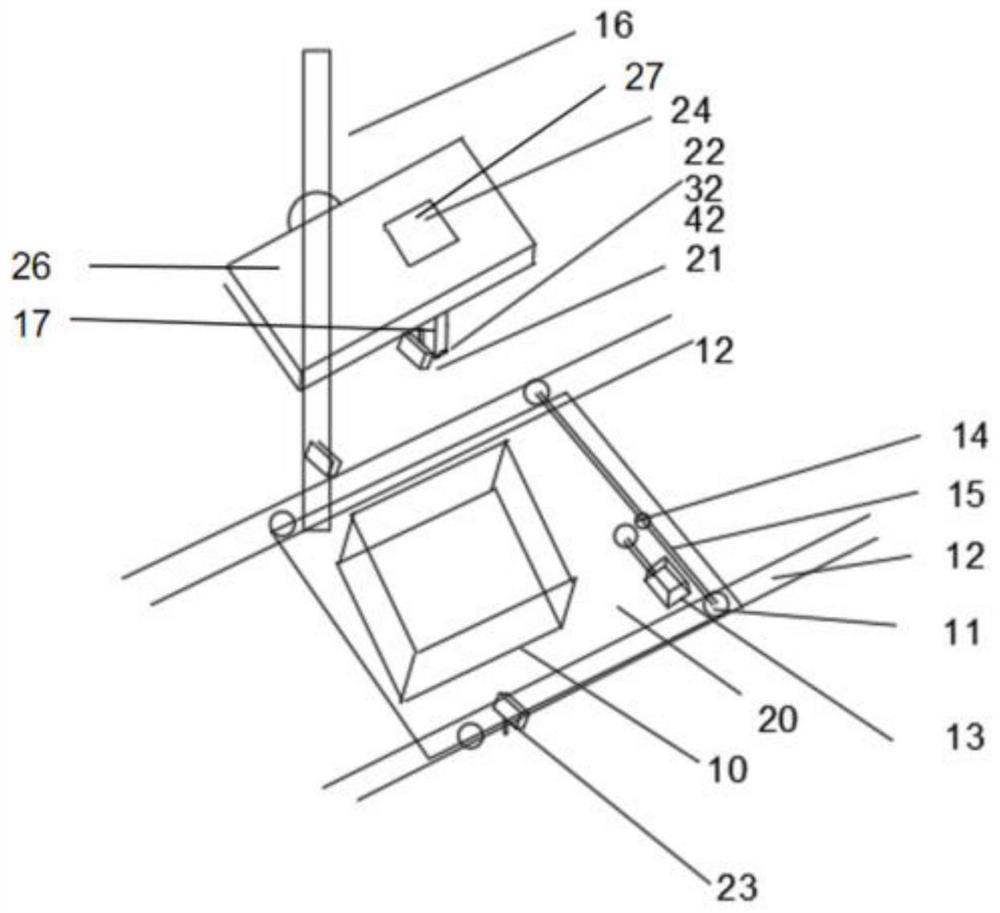

[0070] The invention provides a method for detecting spots on the surface of ceramic products. The whole process of the detection method is as follows: figure 1 As shown, the schematic diagram of the detection equipment is shown in figure 2 shown.

[0071] The spot detection method on the surface of ceramic products specifically comprises the following steps:

[0072] S1. Use testing equipment to take pictures of ceramic products under different light sources, obtain image information under white, red and yellow light sources, and preprocess the images to obtain pictures under white light source, pictures under red light source and pictures under yellow light source;

[0073] S2. Identify candidate initial points on the edge of the spot, specifically including the following sub-steps:

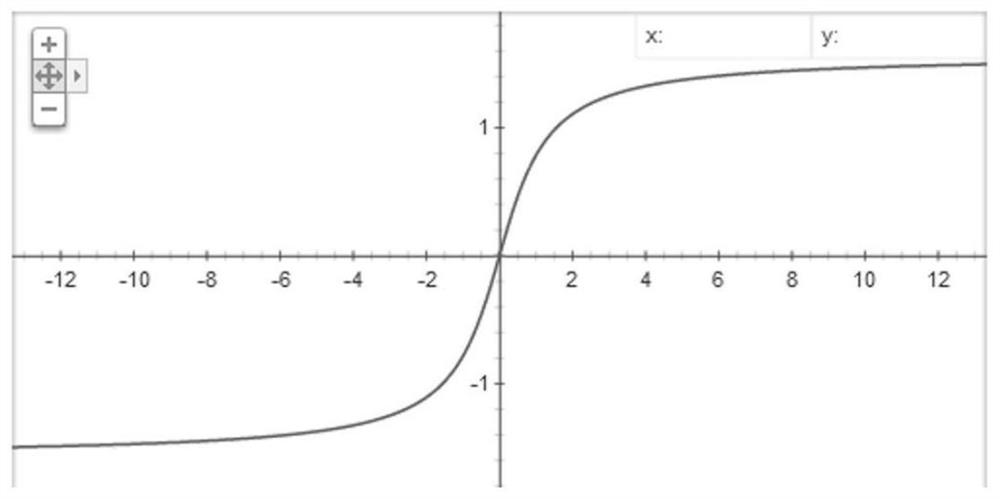

[0074] S21. Determine the candidate initial points associated with the edge stripe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com