Harmonic reducer disassembly and assembly teaching module for industrial robot

A technology of harmonic reducer and industrial robot, applied in teaching models, instruments, educational appliances, etc., can solve the problems of simple training subjects, inability to achieve teaching objectives, single types of teaching tasks, etc., and achieve great market promotion prospects and good Teaching function, rich effect of parts specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

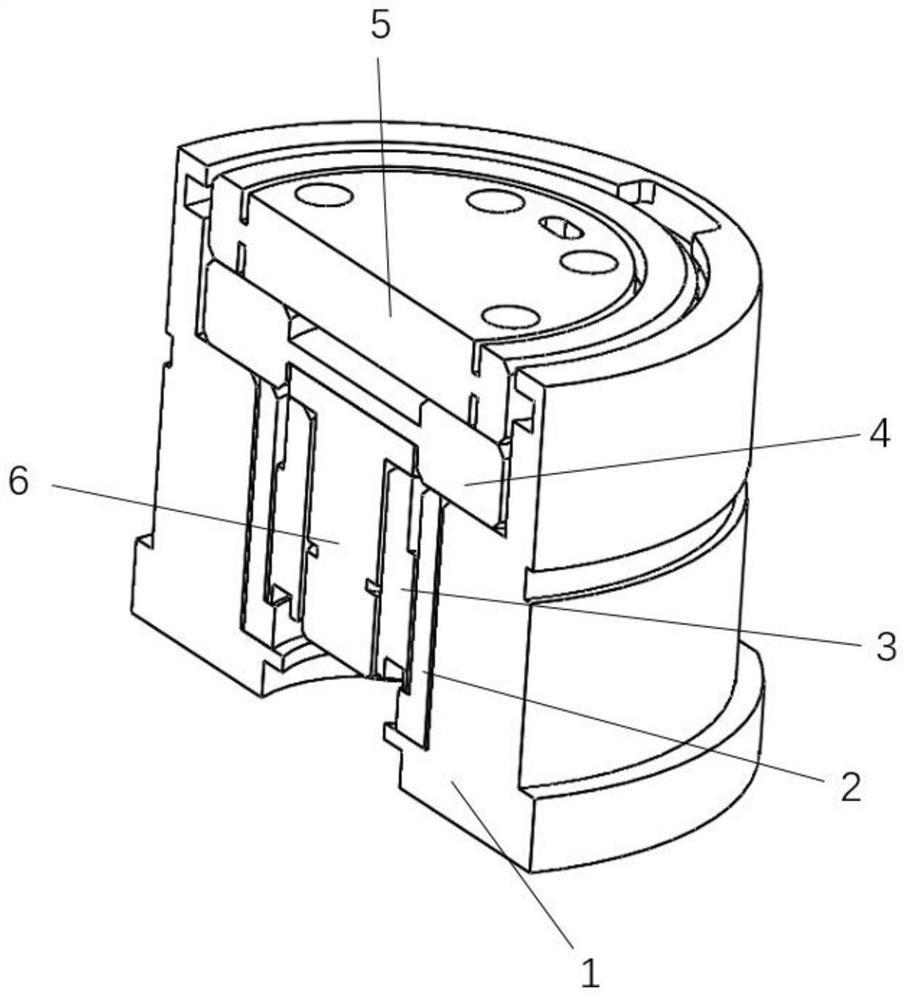

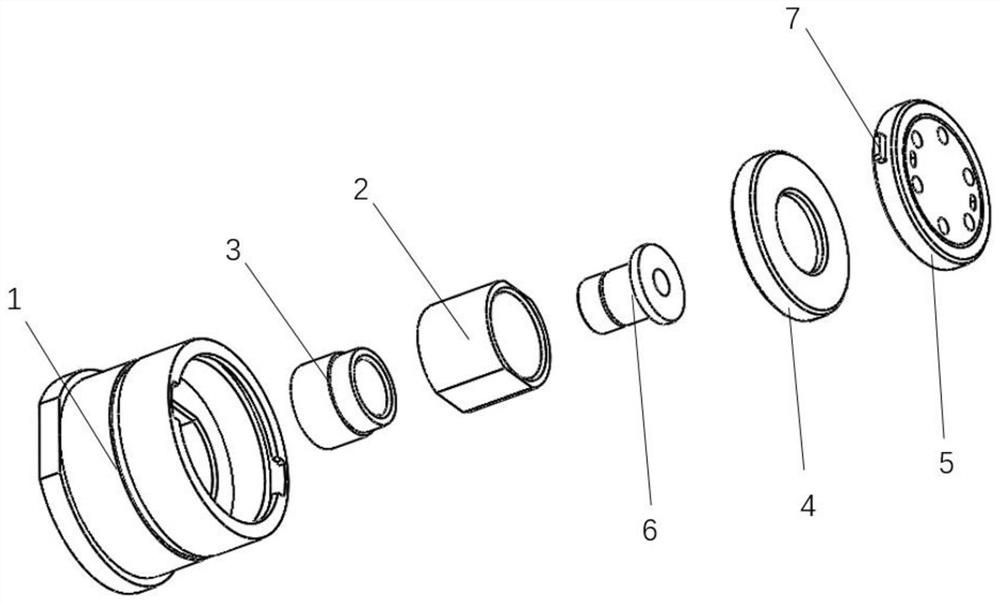

[0012] The invention provides a disassembly and assembly teaching module for a harmonic reducer for industrial robots, which is characterized in that it includes a steel wheel 1, a flexible wheel 2, a wave generator 3, a retaining ring 4, an end cover 5, a shaft sleeve 6, and a steel wheel 1 The interior of the flexible spline 2 is fitted with a wave generator 3 and a shaft sleeve 6, and the shaft sleeve 6 is fitted inside the wave generator 3; the upper end of the shaft sleeve 6 is provided with a retaining ring 4, and the retaining ring 4 is set Inside the steel wheel 1, the upper end of the retaining ring 4 is provided with an end cover 5, and buckles 7 are respectively installed on the front and rear side walls of the end cover 5, and the buckle 7 and the end cover 5 are integrally structured; The sides are respectively provided with card slots; the end cover 5 is respectively connected to the steel wheel 1 through the buckle 7 and the card slot; the flexible wheel 2 is fix...

Embodiment 2

[0015] When the present invention is in use, that is, when showing the disassembly and assembly teaching process of the harmonic reducer to the students, the steel wheel 1 is first fixed and used as a base, and then the flex spline 2, the wave generator 3 and the bushing 6 are placed in sequence Installed into the steel wheel 1, wherein the wave generator 3 and the shaft sleeve 6 are installed in the steel wheel 1 through the flexible spline 2, and the shoulder part 6-1 of the shaft sleeve 6 is installed at the lower end of the wave generator 3 , and then, install the retaining ring 4 into the steel wheel 1, so as to use the retaining ring 4 to realize the fixation of the flexible spline 2 and the bushing 6, and finally, only need to attach the end cover 5 with the buckle 7 to the buckle 7 Just embed it inside the card slot opened on the upper end of the steel wheel 1. Specifically, the place where the end cover 5 is provided with the buckle 7 is facing the card slots on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com