A brush device and a motor

A brush device and brush technology, applied in the direction of electromechanical devices, circuits, collectors, etc., can solve the problems of reduced friction, increased maintenance costs, motor maintenance obstacles, etc., to reduce loss, reduce maintenance costs, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

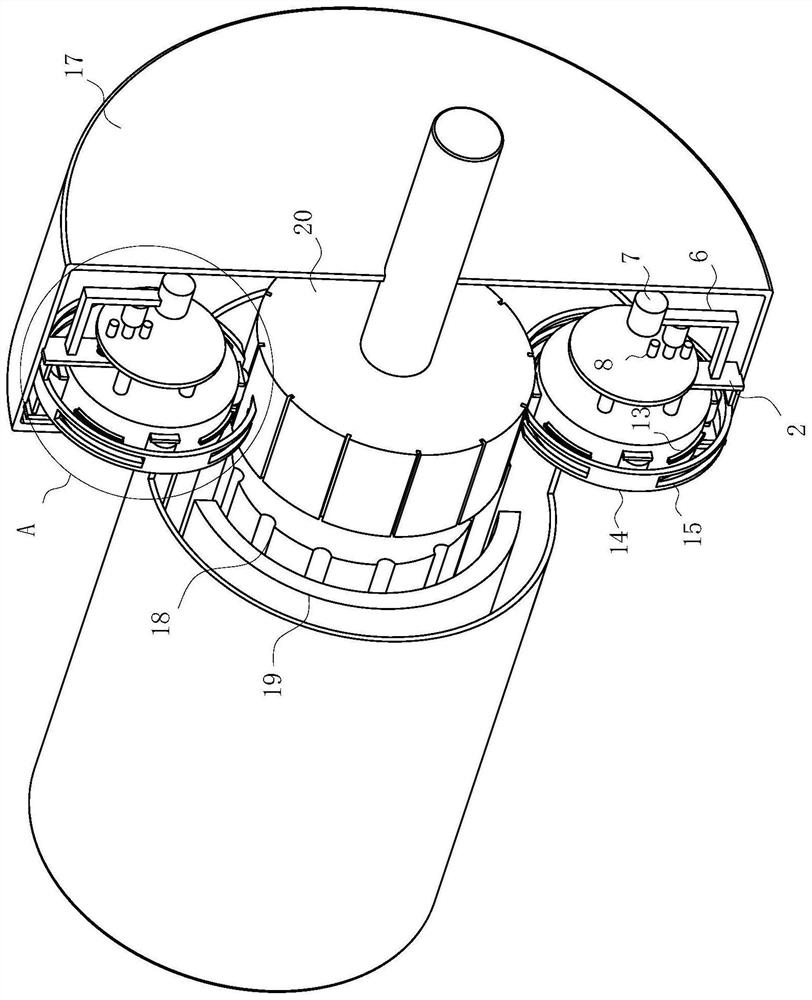

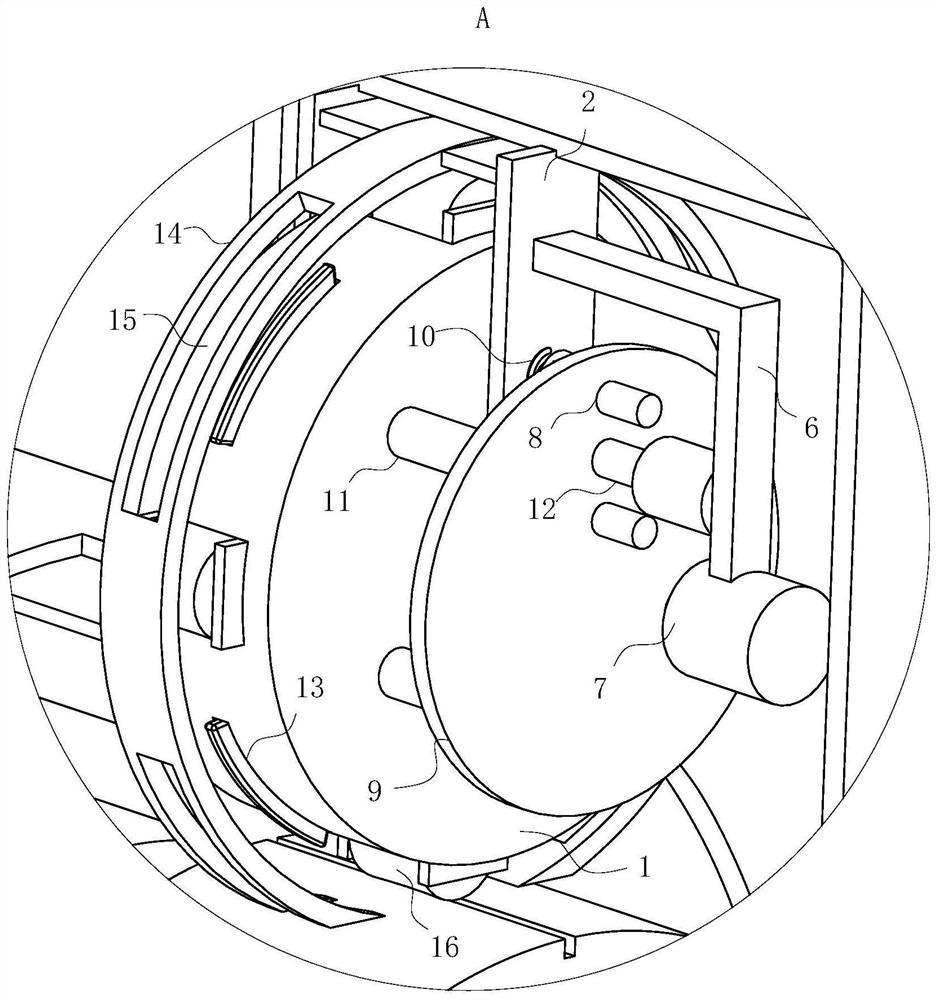

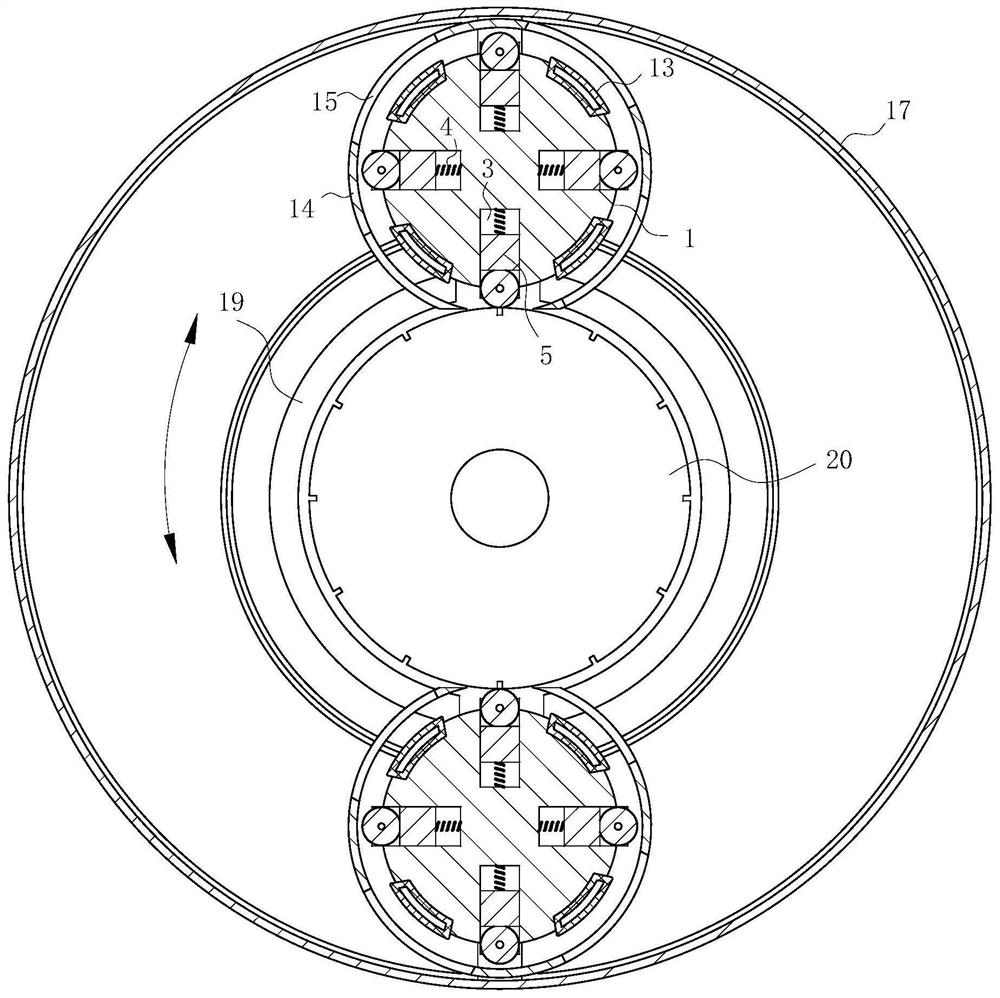

[0025] As a specific embodiment of the present invention, the end of the brush 5 away from the center of the turntable 1 is provided with a mounting groove, and a rotating shaft is installed in the mounting groove, and a roller 16 is fixed on the surface of the rotating shaft. 16 is consistent with the material of the brush 5; when working, the brush 5 will produce friction with the commutator when it is working, and the brush 5 will also slide on the surface of the commutator during the replacement process. The sliding friction not only makes the brush 5 The replacement of the electric brush 5 is also affected, and the brush 5 is more easily consumed; by providing a roller 16 at the end of the brush 5, the sliding friction is changed into rolling friction by using the rolling between the roller 16 and the commutator, thereby The consumption of the electric brush 5 is reduced, and the service life of the electric brush 5 is prolonged, thereby further improving the service life ...

Embodiment approach

[0026] As a specific embodiment of the present invention, the width value of the through hole 15 is greater than the width value of the rubber rod 13 and smaller than the width value of the roller 16, the fracture of the guide rail 14 overlaps at the position of the through hole 15, and the guide rail 14 is provided with a buffer chamfer at the fracture; during work, the fracture of the guide rail 14 is cut by the through hole 15, so that the rubber rod 13 can pass directly through the fracture of the guide rail 14, and then the turntable 1 can rotate smoothly; the guide rail 14 There is a buffer chamfer at the fracture of the guide rail 14 so that the fracture of the guide rail 14 is tangent to the surface of the commutator, so that the brush 5 is in smooth contact with the commutator when it moves to the commutator, avoiding violent collisions, thereby avoiding Damage to the rotating shaft and the roller 16 occurs; the width of the through hole 15 not only ensures its positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com