Collaborative optimization method and system suitable for power distribution room equipment fault judgment

A collaborative optimization and equipment failure technology, applied in electrical components, circuit devices, AC network circuits, etc., can solve the problems of low cost performance of detection methods, detection accuracy of old and fault-prone equipment, and heavy workload of inspection personnel. Improve processing efficiency, reduce manual inspection costs, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

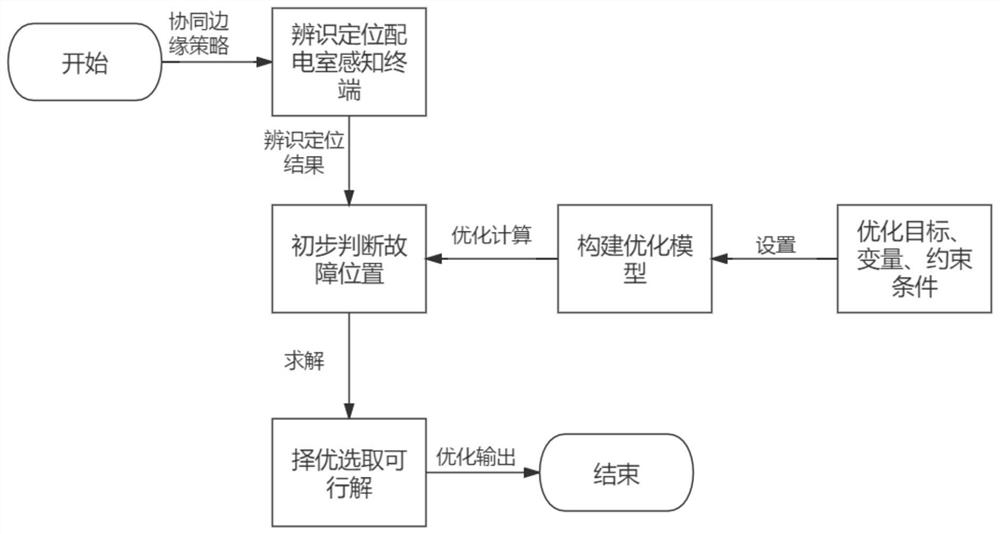

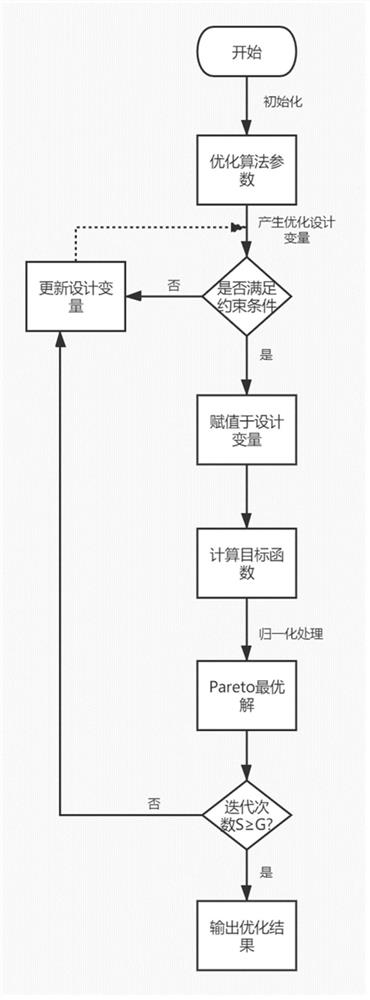

[0035] refer to figure 1 and figure 2 , which is the first embodiment of the present invention, provides a collaborative optimization method suitable for fault judgment of power distribution room equipment, including:

[0036] S1: Use the collaborative edge strategy to identify and locate multiple partial discharge sources and abnormal sounds of equipment for the sensing terminals in the power distribution room. It should be noted that before performing identification and positioning, it also includes:

[0037] Collect the state quantity data of the sensing terminal in the power distribution room for normalization processing to form a sample data set;

[0038] Construct a deep learning model based on a deep convolutional network, input a sample data set for recognition training, and stop training until the output recognition result is consistent with the training sample label;

[0039] Use the trained deep learning model to perform fusion analysis on the state quantity;

...

Embodiment 2

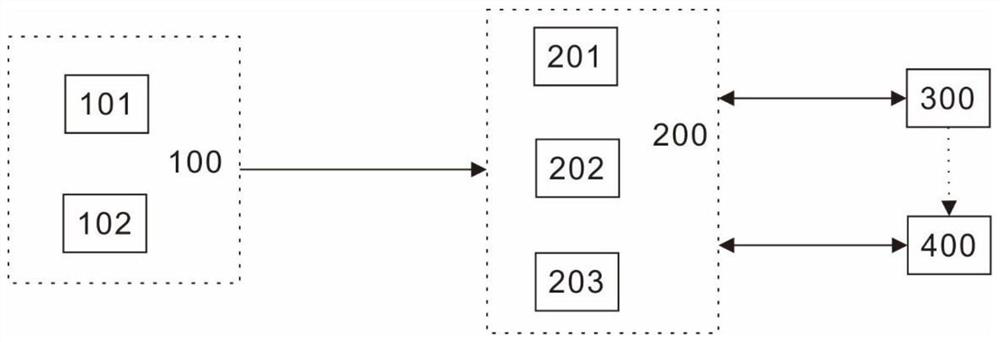

[0087] refer to image 3, is the second embodiment of the present invention, which is different from the first embodiment in that it provides a collaborative optimization system suitable for fault judgment of equipment in a power distribution room, including:

[0088] The information collection module 100 is used to collect the real-time state quantity and historical state quantity of the operation of each equipment in the power distribution room, which includes a camera 101 and a sensor 102. The camera 101 is used to capture image information of each equipment, and the sensor 102 is used to perceive the operating state of the equipment. quantity data.

[0089] The data processing center module 200 is connected to the information collection module 100, and includes a calculation unit 201, a training unit 202, and an input and output unit 203. The calculation unit 201 is used to calculate and process the state quantity data transmitted by the information collection module 100, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com