Crushing and sorting treatment equipment for waste building structures

A technology for processing equipment and structures, applied in grain processing, mechanical equipment, solid separation, etc., can solve the problems of construction waste falling, ecological environment impact, high cost of construction waste transportation, etc., and achieve the effect of high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

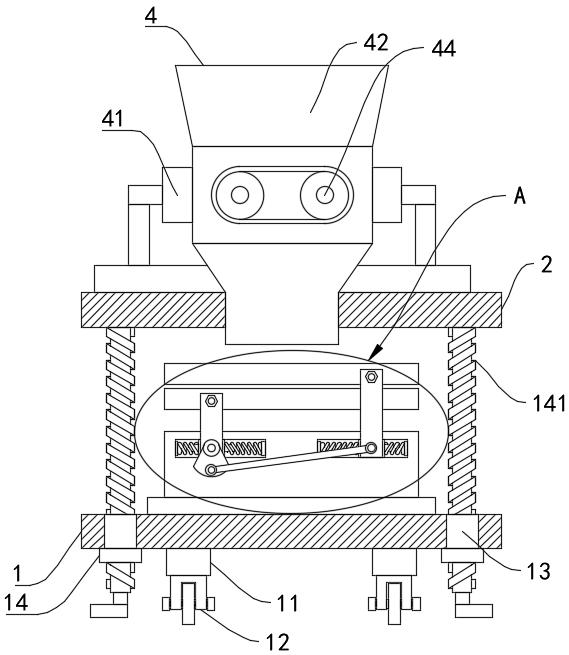

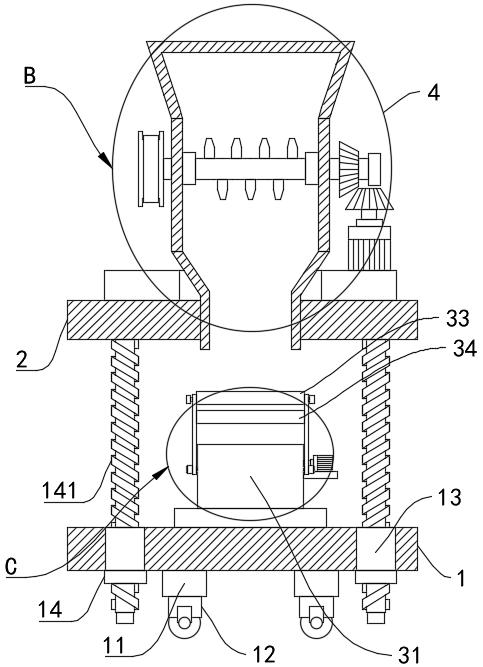

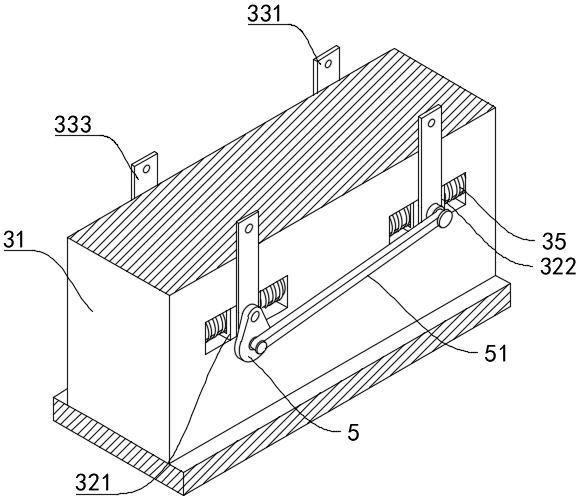

[0031] Such as Figure 1-7 As shown, a crushing and sorting processing equipment for abandoned building structures includes a fixed base 1 and a supporting upper plate 2, the lower end of the fixed base 1 is fixedly connected with a connecting block 11, and the lower end of the fixed base 1 is fixedly connected with a ball Nut 14, the middle part of ball nut 14 is threadedly connected with threaded rod 141, and the quantity of threaded rod 141 is four, is perforated and connected to the four corners of fixed base 1 respectively, and the bottom surface of the lower end of threaded rod 141 is fixedly connected with rotating handle, which is used for rotating the handle. When the threaded rod 141 is rotated, the upper end of the threaded rod 141 is perforated and connected in the through groove 13 , and the top surface of the threaded rod 141 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com