Silicone rubber coating spraying device

A technology of spraying device and silicone rubber, which is applied in spraying device, spray booth, chemical instrument and method, etc., can solve the problems of reducing equipment insulation, potential safety hazards, and leakage of coating, so as to improve work efficiency and reduce potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

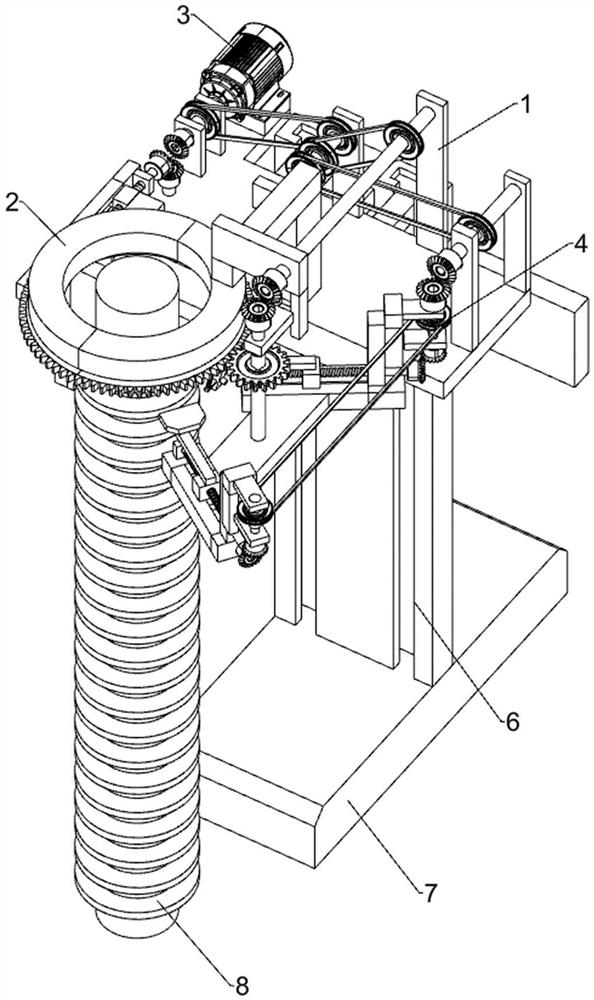

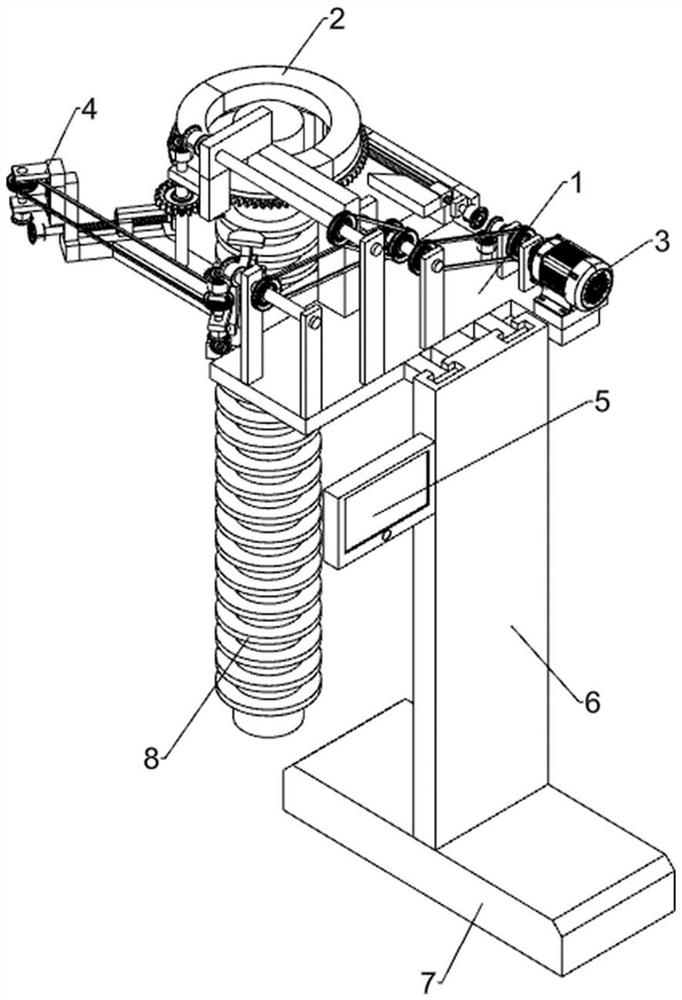

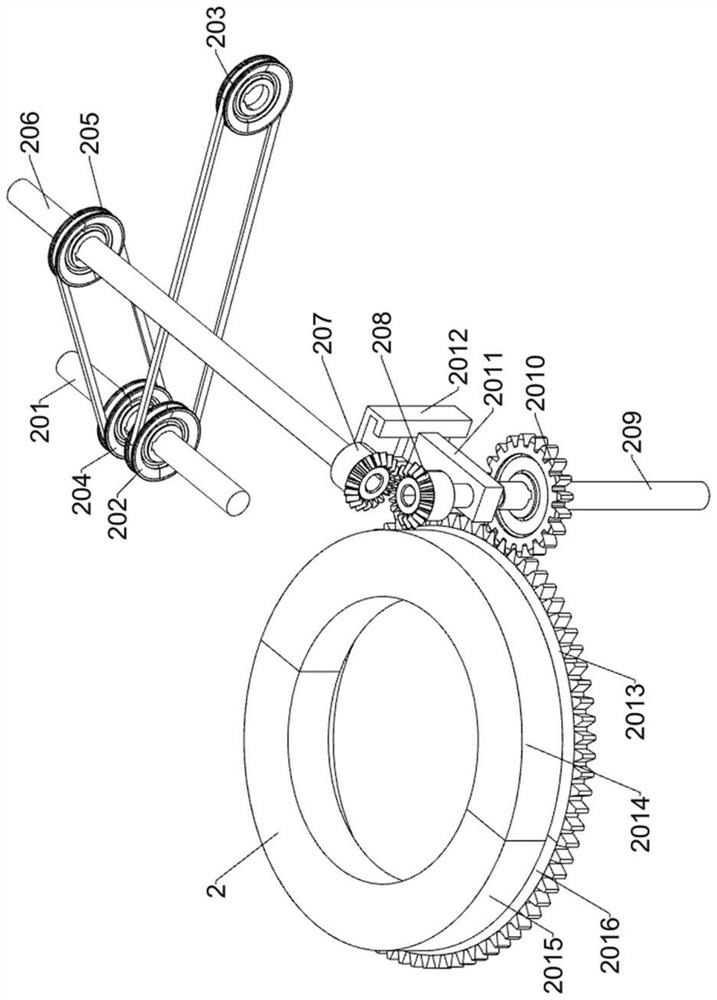

[0027] A silicone rubber paint spraying device, such as Figure 1-6 As shown, it includes workbench 1, transmission mechanism 2, ash removal mechanism 3, spraying mechanism 4, control panel 5, first electric slide rail 6, magnetic base 7 and composite cross-arm insulator 8; the upper part of workbench 1 and the transmission mechanism 2 phase connection; the upper part of workbench 1 is connected with ash removal mechanism 3; the upper part of workbench 1 is connected with spraying mechanism 4; connection; the transmission mechanism 2 is connected with the spraying mechanism 4; the ash removal mechanism 3 is in contact with the composite cross-arm insulator 8; the first electric slide rail 6 is connected with the control panel 5; the bottom of the first electric slide rail 6 is connected with the magnetic base 7 connect.

[0028] Working principle: When preparing for work, first remove part of the structure of the transmission mechanism 2, and then move the device to the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com