A high-efficiency pipeline automatic welding device

A fully automatic welding and pipeline technology, applied in welding equipment, electrode support devices, tubular objects, etc., can solve problems such as inconvenient rotation, and achieve the effect of ensuring quality, ensuring normal operation, and reducing electrical equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

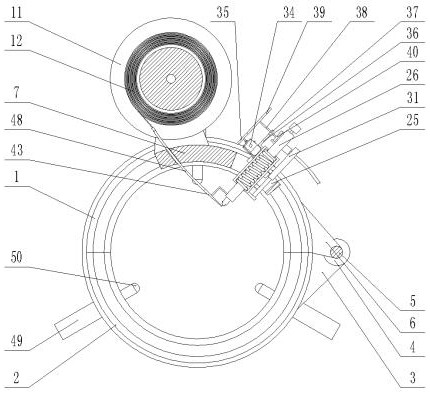

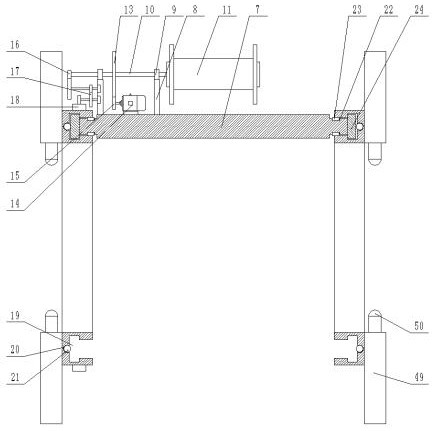

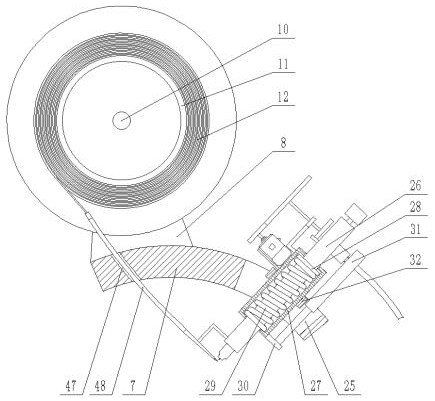

[0031]The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8 Shown:

[0032] A high-efficiency automatic welding device for pipelines, including two rotating splicing fixed frame devices, the two rotating splicing fixed frame devices are symmetrically distributed, one side of the rotating splicing fixed frame device is equipped with a pipe fixing device, and the two rotating splicing fixed frame devices There is a limit device at the joint of the fixed frame device, and an arc-shaped sliding platform device is provided between the two rotating spliced fixed frame devices. The arc-shaped sliding platform device is equipped with a welding wire automatic feeding device, and the Equipped with automatic adjustment welding device;

[0033] The rotating spliced fixed frame device includes an upper semicircular fixed frame 1 and a lower semicircular fixed frame 2, a spliced bearing seat 3 is installed on one side surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com