Inner side pedal of numerical control milling machine

A CNC milling machine and foot pedal technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems such as easy slipping of the foot pedal, and achieve the purpose of increasing friction and increasing the degree of lubrication Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

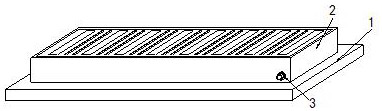

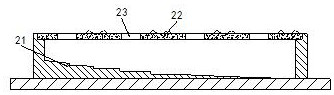

[0027] Its structure includes a base 1, a pedal 2, and a sewage outlet 3. The upper end of the base 1 is provided with a pedal 2, and the sewage outlet 3 is located at the bottom of the front end of the pedal 2. The pedal 2 includes a storage Water tank 21, liquid guiding device 22, water inlet 23, described water accumulation tank 21 is arranged on the inside of pedal 2, and height gradually decreases from one end to the other end, and described liquid guiding device 22 is provided with more than four cores, and horizontal Arranged on the top of the pedal 2, there are more than four water inlets 23, which are respectively located at the two ends of the liquid guiding device 22.

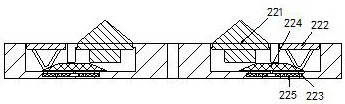

[0028] The liquid guiding device 22 includes a water guiding block 221, a trigger block 222, a sliding groove 223, a sliding block 224, and a return spring 225. There are two wa...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The trigger block 222 includes a supporting link b1, a mounting seat b2, and a contact layer b3. The supporting link b1 is V-shaped, and the mounting seat b2 is embedded on the top of the supporting link b1. The contact layer b3 Attached to the top of the mounting seat b2, the contact layer b3 is made of rubber, and the top end surface is zigzag, which is beneficial to increase the friction between the trigger block 222 and the sole.

[0034] The supporting link b1 includes a connecting seat b11, a sliding friction block b12, a ball b13, and a friction device b14. The connecting seat b11 is embedded at both ends of the top of the supporting link b1, and the sliding friction block b12 is arranged At the bottom of the rod b1, there are more than three balls b13 arranged horizontally at the bottom of the sliding friction block b12. The friction device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com