Positioning device for machining outer circle gear teeth of automobile differential gear

An automotive differential and positioning device technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of high scrap rate, small application range, single positioning diameter, etc., and achieve diversified positioning diameters and good clamping effect. , the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

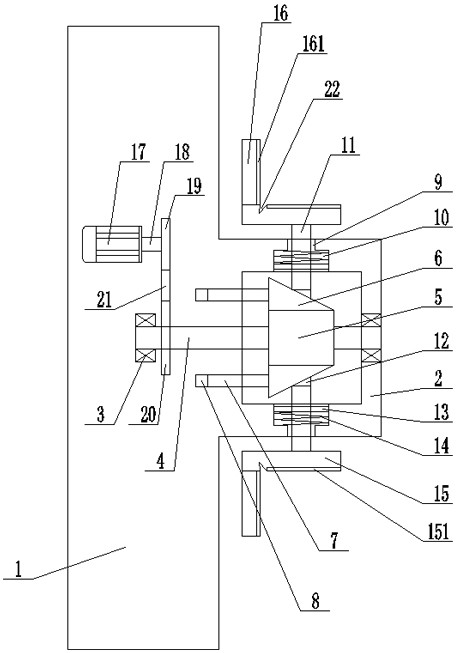

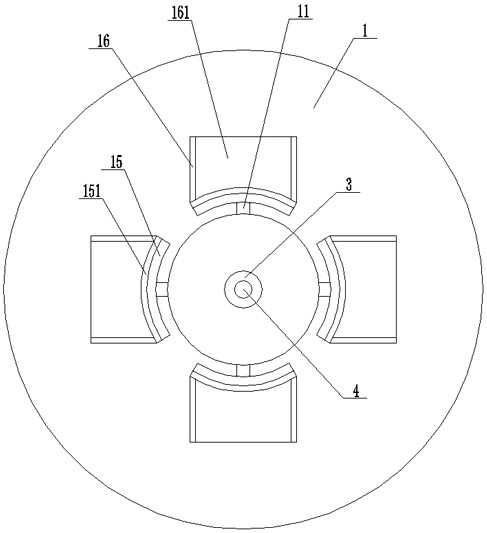

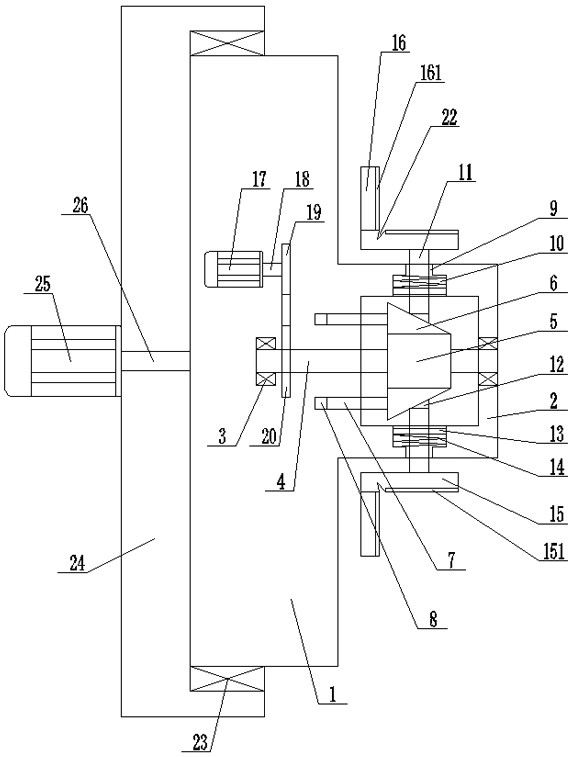

[0015] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 , figure 2 , image 3 As shown, the positioning device for the processing of the outer circular gear of the automobile differential gear includes: a fixed plate 1, an annular fixed sleeve 2 is arranged in the middle of the right side of the fixed plate 1, and an annular fixed sleeve 2 is arranged between the fixed plate 1 and the annular fixed sleeve. The middle part of 2 is provided with a transverse screw 4 through the rotation of the first bearing seat 3, and a transverse screw sleeve 5 cooperating with the transverse screw 4 is arranged in the annular fixed sleeve 2, and several horizontal screw sleeves 5 are uniformly arranged on the The first oblique wedge 6 is provided with transverse guide rods 7 respectively at the left end of the first oblique wedge 6, and a number of horizontal gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com