Building module processing system

A module processing and construction technology, applied in the field of building material manufacturing, can solve the problems of inability to maintain product quality, inability to clean the mold, reduce work efficiency, etc., and achieve the effects of simple structure, convenient operation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

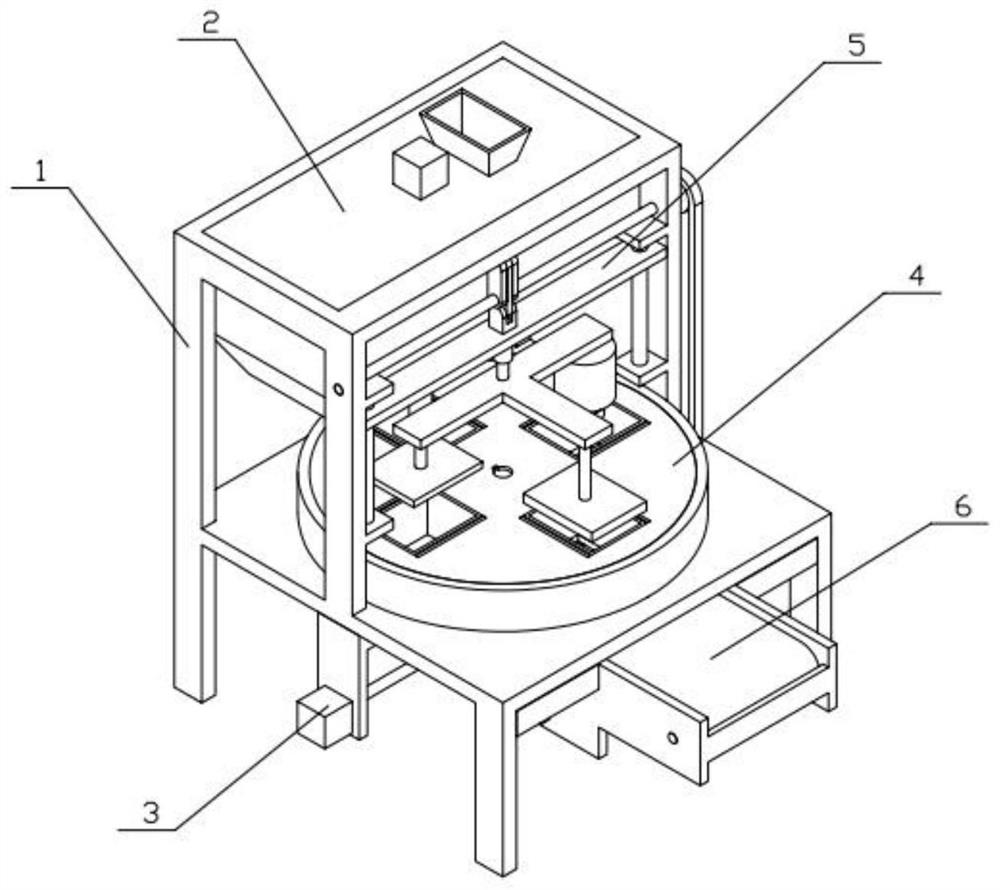

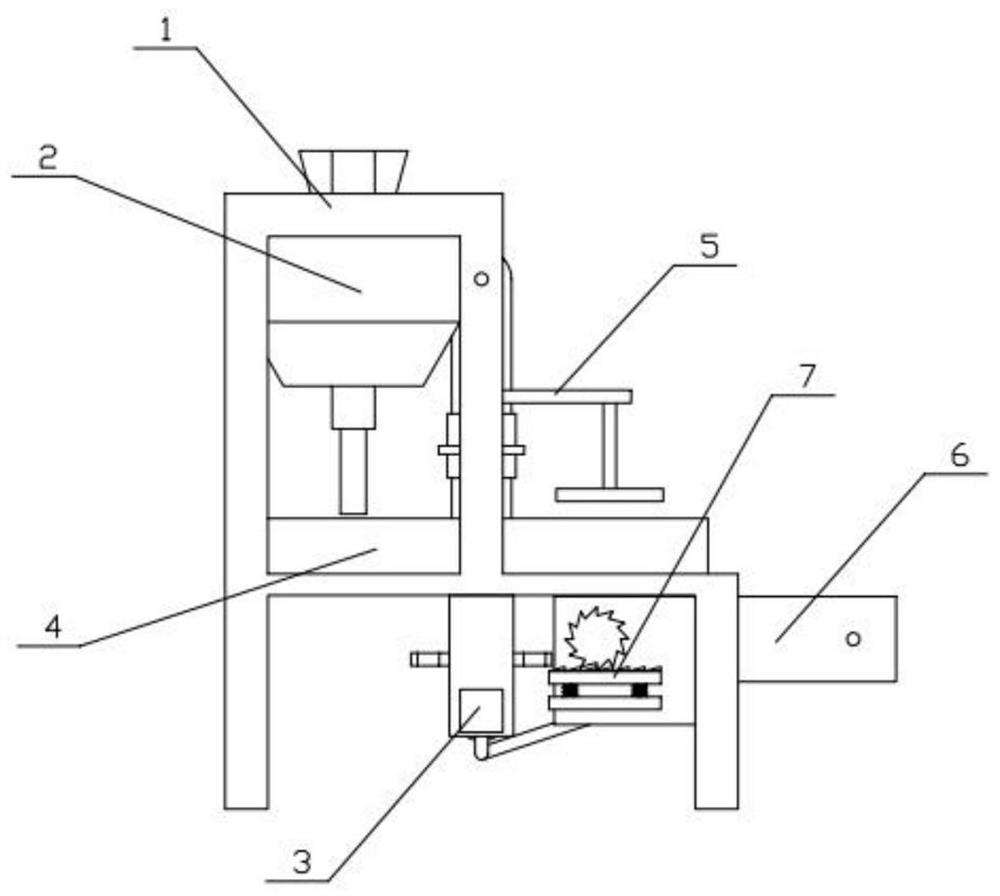

[0034] Combine below Figure 1-10 Describe this embodiment, a building module processing system, including a frame 1, a feeding mechanism 2, a power mechanism 3, a rotating mechanism 4, an extrusion mechanism 5, a conveying mechanism 6 and a transmission mechanism 7, the upper end of the frame 1 The feeding mechanism 2 is fixedly connected, the power mechanism 3 is fixedly connected to the lower end of the frame 1, the extruding mechanism 5 is connected to the frame 1, the extruding mechanism 5 is connected to the power mechanism 3, and the conveying mechanism 6 is fixedly connected to the On the frame 1, the transmission mechanism 7 is connected to the conveying mechanism 6, and the transmission mechanism 7 is connected with the power mechanism 3; The mutual cooperation of the extruding mechanism 5 and the intermittent movement of the rotating mechanism 4 and the conveying mechanism 6 are realized to complete extrusion, demoulding, cleaning and conveying, which improves the w...

specific Embodiment approach 2

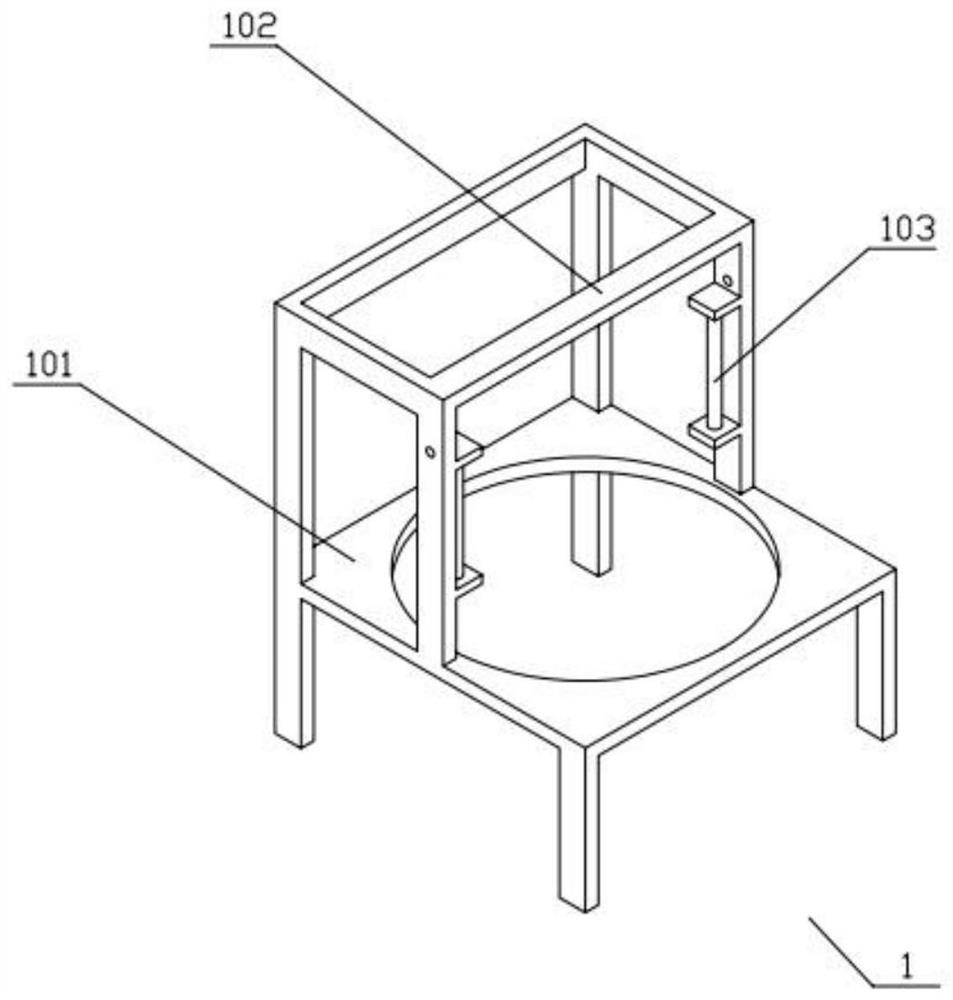

[0036] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the frame 1 includes a base 101, a bracket I 102 and a guide frame 103, the upper part of the base 101 is fixedly connected with the bracket I 102, and both sides of the bracket I 102 are fixedly connected with guide Frame 103 ; the setting of the guide frame 103 can ensure that the extruding mechanism 5 moves along the direction of the guide frame 103 .

specific Embodiment approach 3

[0038] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the second embodiment, the feeding mechanism 2 includes a box body I201, a motor I202, a stirring frame 203 and a solenoid valve 204, the box body I201 is fixedly connected to the bracket I102, and the motor I202 Fixedly connected to the upper end of the box I201, the output shaft of the motor I202 is fixedly connected to the stirring frame 203, and the lower part of the box body I201 is fixedly connected to the solenoid valve 204; the stirring frame 203 is driven by the driving motor I202 to rotate, and the stirring frame 203 can Stir the material to prevent the material from agglomerating in the box I201, and prevent the material from clogging the lower part of the box I201. Institution 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com