Desulfurization, denitration and dust removal equipment for industrial waste gas

A technology for desulfurization, denitrification, and dust removal equipment, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. Vibrating filter screen and other problems, to achieve the effect of high production efficiency, ensuring sustainable progress and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Exemplary embodiments of the present application are described below with reference to the accompanying drawings. It should be understood that these specific instructions are only used to teach those skilled in the art how to implement the present application, and are not used to exhaust all possible ways of the present application, nor are they used to limit the scope of the present application:

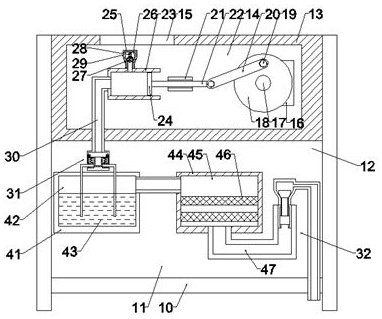

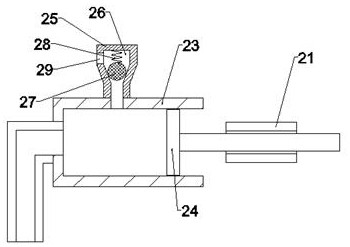

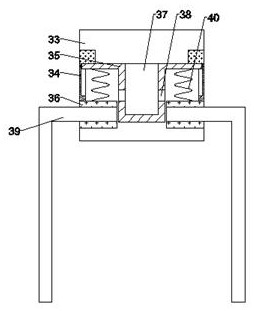

[0014] Such as Figure 1-Figure 4 As shown, an industrial waste gas desulfurization, denitrification and dust removal equipment according to an embodiment of the present invention includes a casing 10, a main operating chamber 11 is provided inside the casing 10, and a set is fixed on the upper end of the main operating chamber 11. Gas mechanism 12, the lower end of the gas collection mechanism 12 is provided with an air pressure valve mechanism 31, and the right end of the air pressure valve mechanism 31 is provided with an air outlet cut-off mechanism 32, and the gas collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com