A method of using an inking device for a gravure printing machine

A gravure printing machine and ink technology, applied in the field of printing, can solve the problems of affecting printing quality, uneven distribution of ink, and inability to effectively adjust the distance between a squeegee device and an ink roller, and achieve the effect of improving the mixing effect and the mixing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

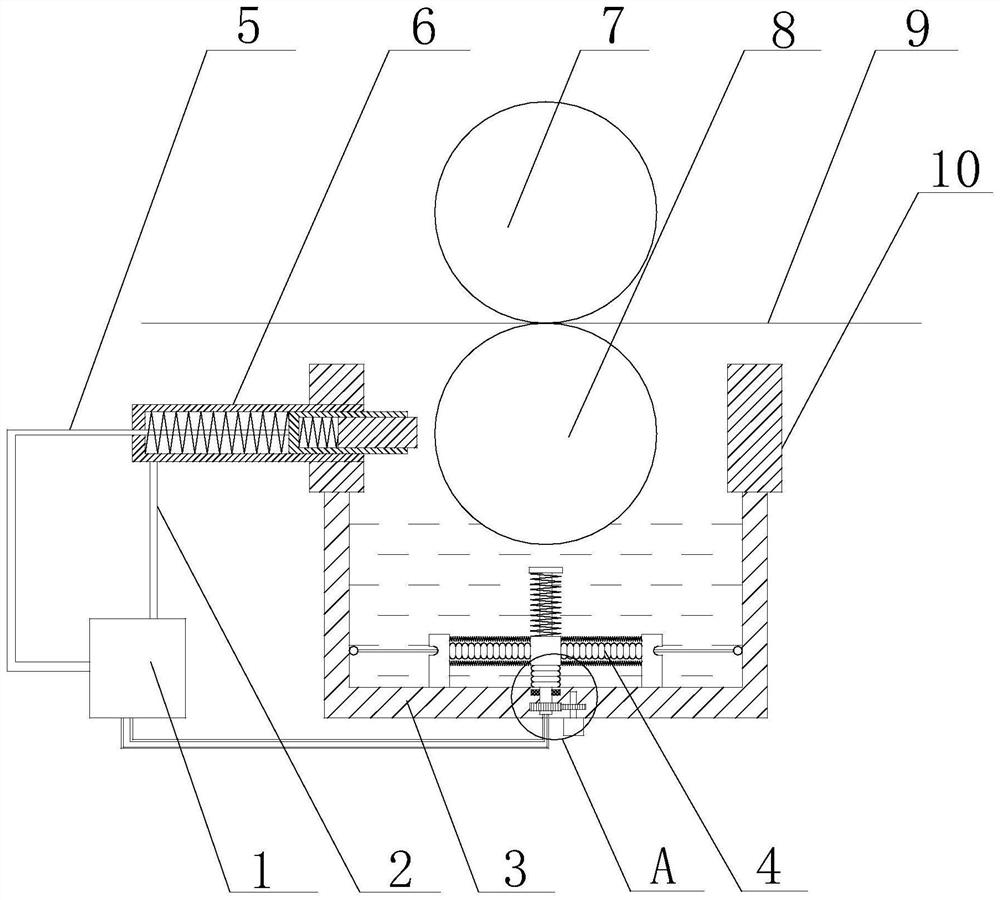

[0049] Such as Figure 1 to Figure 9 As shown, a method for using an inking device of a gravure printing machine of the present invention comprises the following steps:

[0050] 1) Start the motor 30, the motor 30 drives the stirring shaft 14 to rotate in the lower tank body 3, and use the second telescopic tube to stir the ink in the lower tank body;

[0051] 2) Start the air pump 1 and feed high-pressure gas into the fourth air pipe 12. The high-pressure gas enters the second telescopic tube 18 through the fourth air pipe 12, forcing the second telescopic tube 18 to move toward the inner wall of the lower pool body 3. The second telescopic tube 18 When moving toward the inner wall of the lower tank body 3, the stirring plate 16 scrapes off the ink attached to the bottom of the lower tank body and mixes it with other inks;

[0052] 3) When the stirring plate 16 moves to fit the inner wall of the lower pool body 3, the air pump 1 is used to inject high-pressure gas into the t...

Embodiment 2

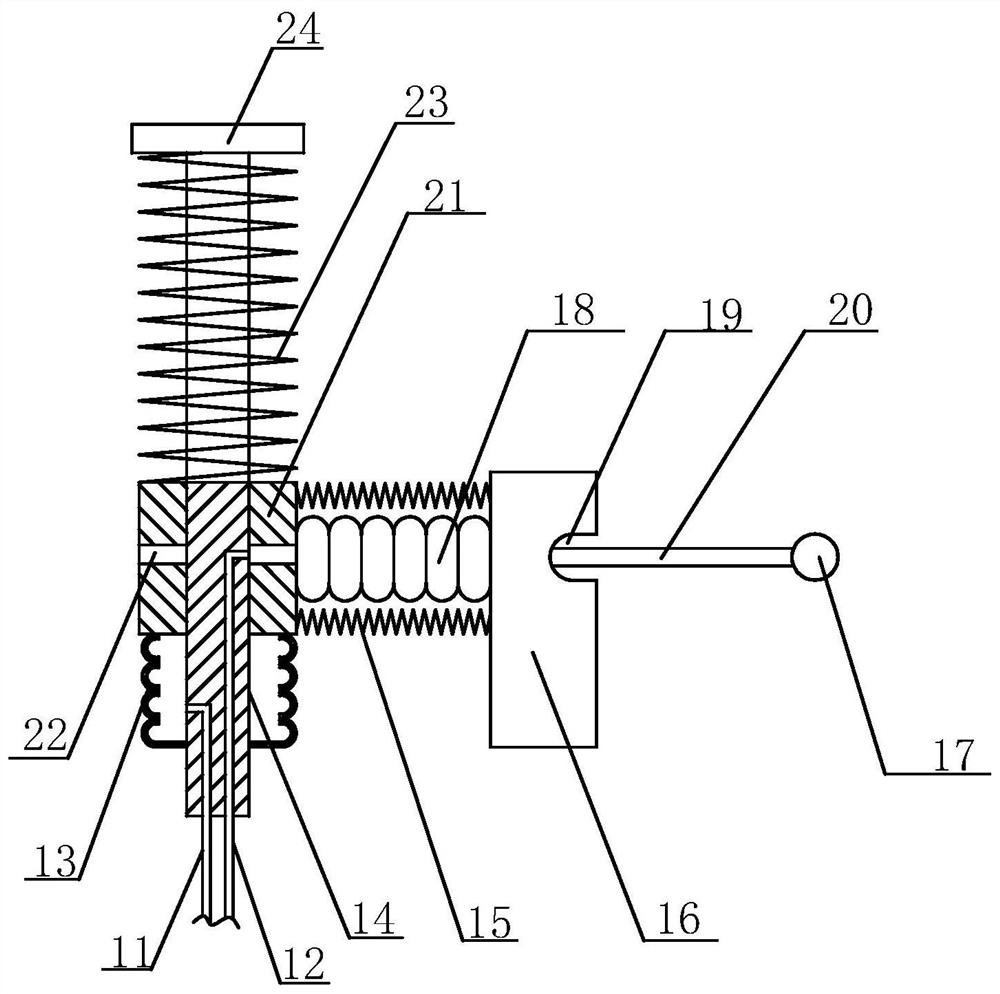

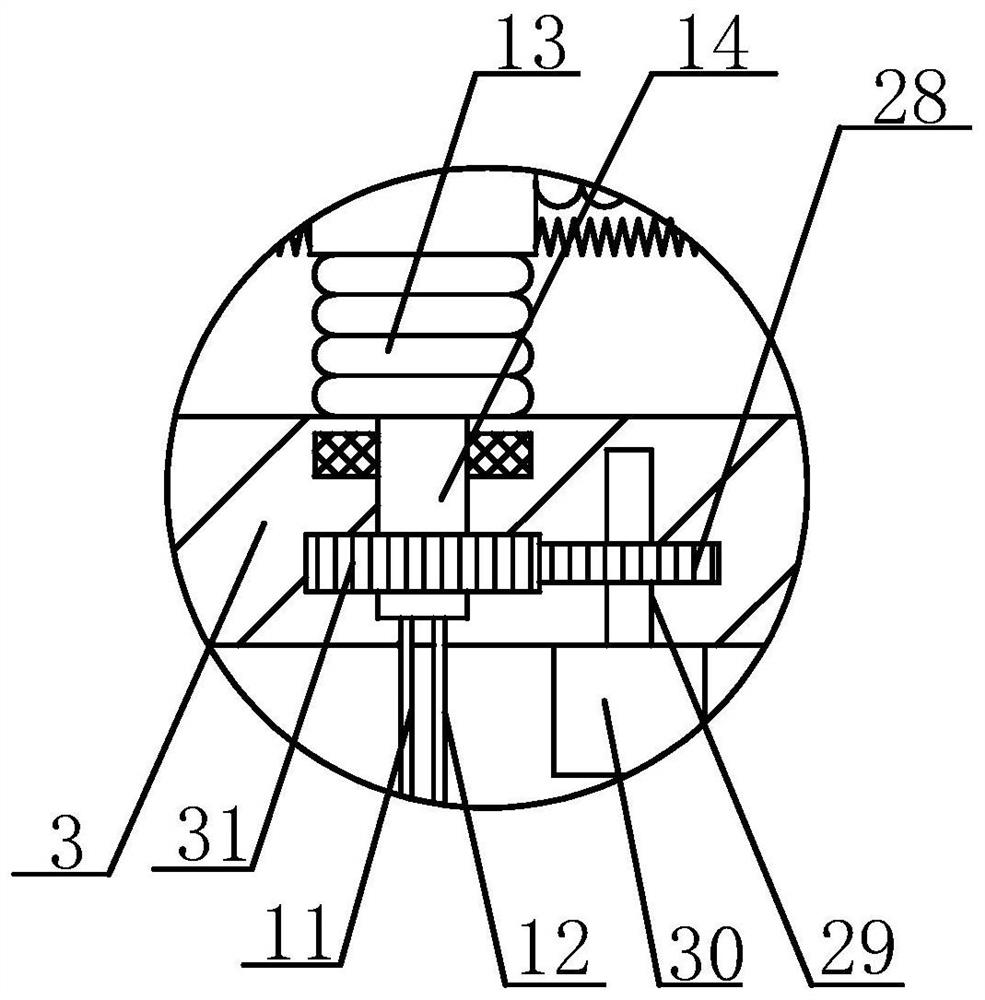

[0059] On the basis of Embodiment 1, the output end of the motor 30 extends into the lower pool body 3, the output shaft 29 of the motor 30 is provided with the first transmission gear 28, and the stirring shaft 14 is also provided with the first transmission gear. The tooth 28 meshes with the second transmission tooth 31 .

Embodiment 3

[0061] On the basis of Embodiment 1, a limit plate 24 is also provided on the top of the stirring shaft 14, a second elastic member 23 is also provided on the stirring shaft 14, and the second elastic member 23 is sleeved on the stirring shaft 14, and The second elastic member 23 is located between the limiting plate 24 and the movable block 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com