Raw material pretreatment device for paper product production

A pretreatment device and paper product technology, applied in the post-treatment of mixture, mixer with rotating stirring device, transportation and packaging, etc., can solve the problems of waste of raw materials, insufficient raw material treatment, increase of production cost, etc., and reduce production The effect of cost, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

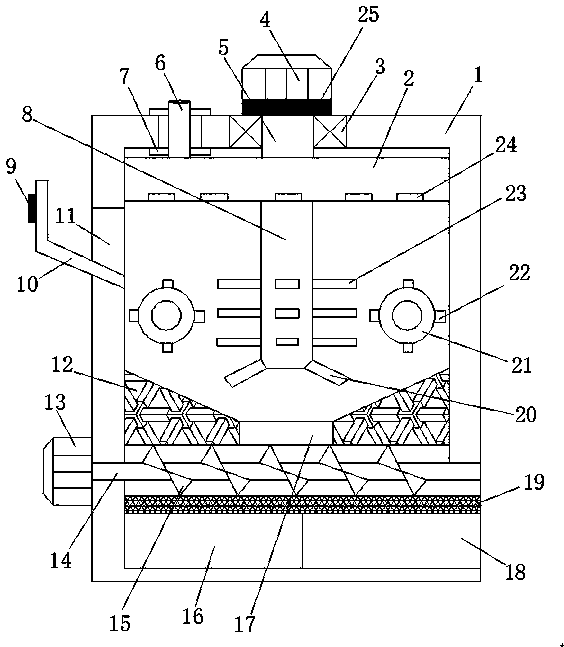

[0016] Embodiment 1: see figure 1 Now, a raw material pretreatment device for paper product production provided by the present invention is described, including a mixing box 1, an air distribution plate 2, a feeding shaft 14 and a turning shaft 21, and the inside of the mixing box 1 is provided with an air distribution plate 2, feeding shaft 14 and turning shaft 21, a connecting bearing 3 is provided between the mixing box 1 and the air distribution plate 2, a stirring motor 4 is provided above the mixing box 1, and a stirring motor 4 is provided above the air distribution plate 2. Water inlet pipe 6, water pipe interface 7 is arranged on both sides of described water inlet pipe 6, agitation shaft 8 is arranged below described agitation motor 4, connecting block 5 is arranged between described agitation motor 4 and agitation shaft 8, and described mixing box 1 side is provided with feeding box 10, and above described feeding box 10 is provided with feeding port 11, and describ...

Embodiment 2

[0017] Example 2: see figure 1 Now, a kind of raw material pretreatment device for the production of paper products provided by the present invention is described. Coarse-toothed stirring blades 23 are provided on both sides of the stirring shaft 8, and fine-toothed stirring blades 23 are provided on both sides of the bottom end of the stirring shaft 8. Blade 20.

Embodiment 3

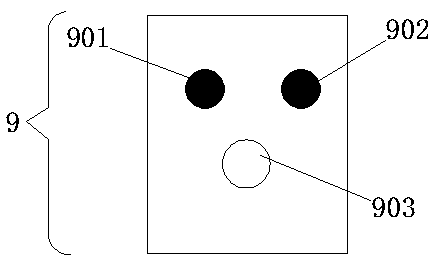

[0018] Embodiment 3: see figure 2 Now, a raw material pretreatment device for paper product production provided by the present invention will be described. The surface of the control panel 9 is provided with a start button 901 , a stop button 902 and an emergency stop button 903 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com