Environment-friendly woven bag printing water-based ink and preparation method thereof

An environmentally friendly, woven bag technology, used in inks, chemical instruments and methods, mixers, etc., can solve the problems of slow drying speed and poor adhesion, and achieve the effects of fast drying speed, improved adhesion and high adhesion strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An environment-friendly printing ink for woven bags, prepared from the following raw materials in parts by weight: 15 parts of acrylic resin aqueous solution, 25 parts of polyacrylate emulsion A, 25 parts of polyacrylate emulsion B, 10 parts of pigment, 0.5 part of wetting and dispersing agent, 0.3 parts of foaming agent, 1 part of wax slurry, 10 parts of deionized water;

[0035] Wherein, the environment-friendly printing ink for woven bags is prepared through the following steps:

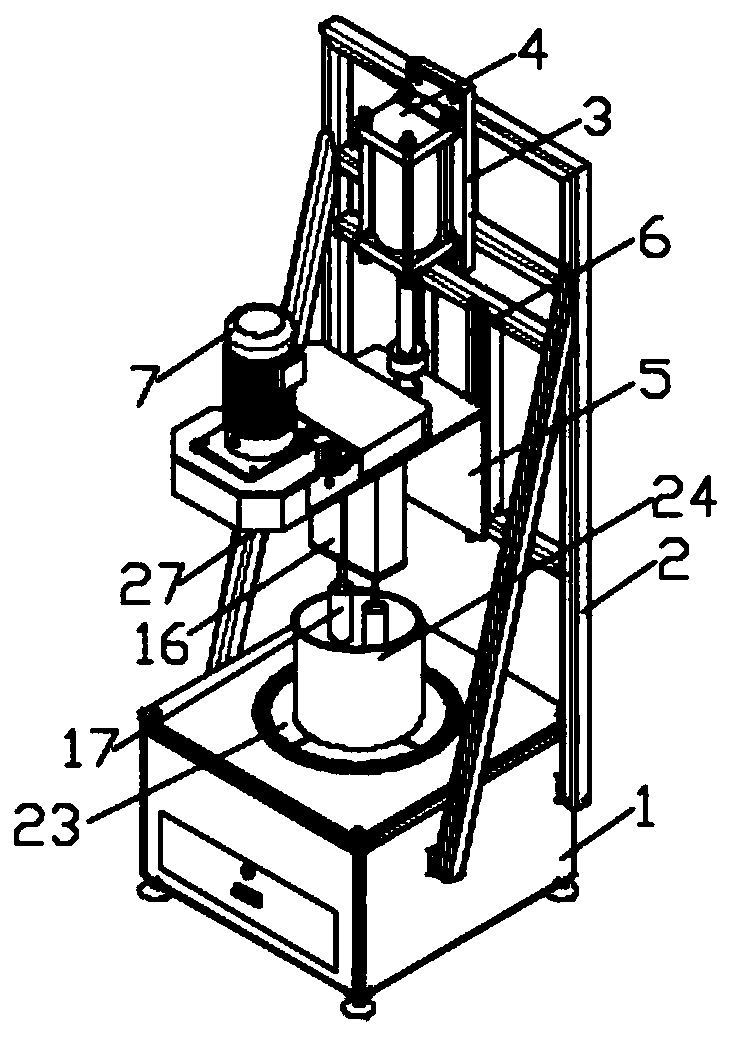

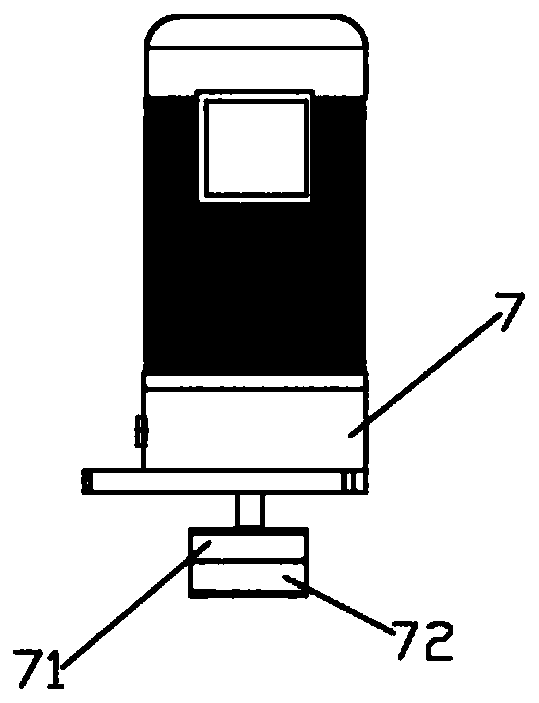

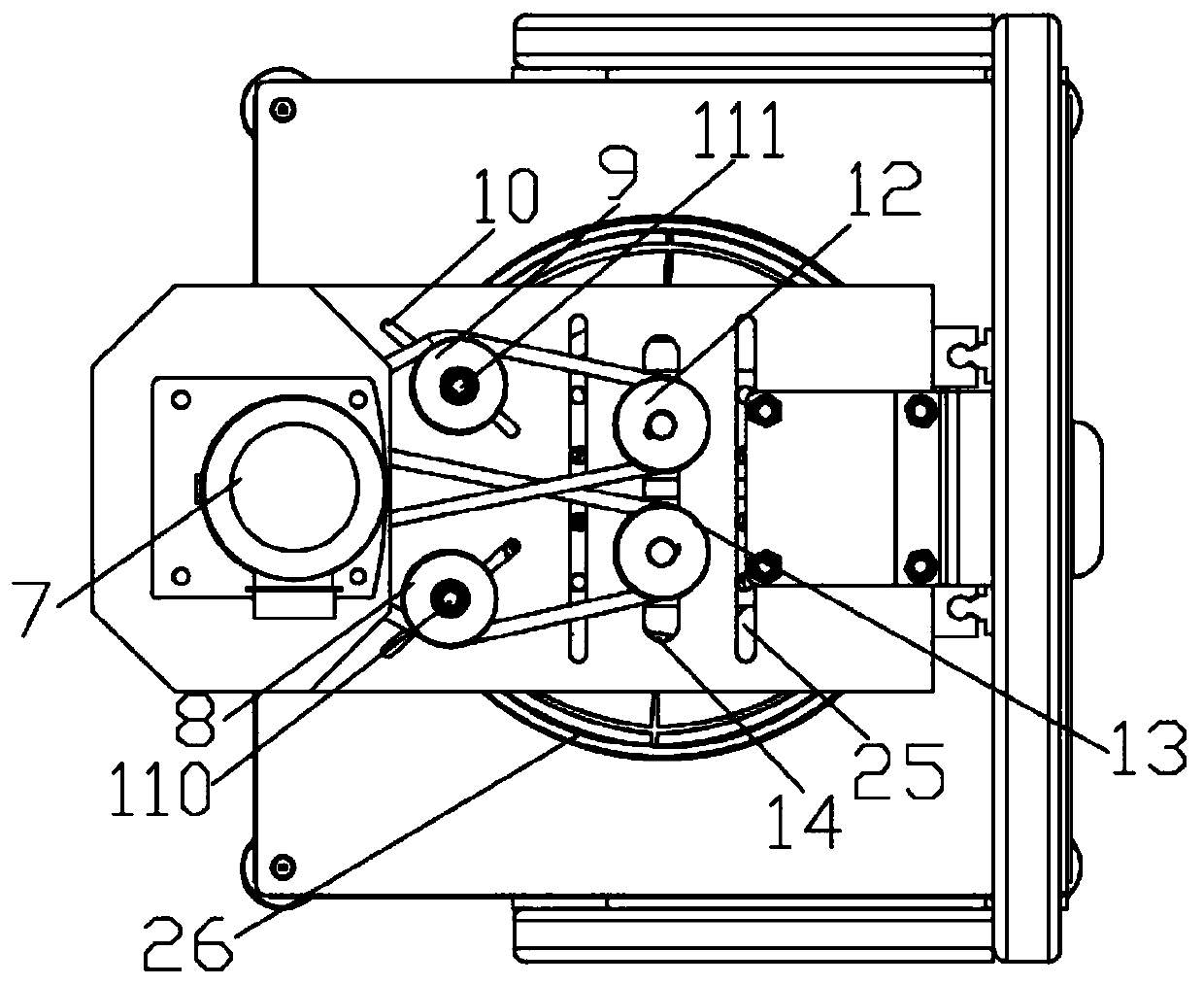

[0036] Step 1: Put the acrylic resin aqueous solution, wetting and dispersing agent, defoamer, pigment, and deionized water into the grinding cylinder 24 of the processing equipment, and adjust two The position of the housing 16 is fixed, and the positions of the first shaft 110 and the second shaft 111 in the two first through grooves 10 are adjusted through the locking sleeve 11 at the same time, and then the first elastic wheel 8 and the second elastic wheel 9 are adjusted. position, so...

Embodiment 2

[0042] An environmentally friendly printing ink for woven bags, prepared from the following raw materials in parts by weight: 20 parts of acrylic resin aqueous solution, 30 parts of polyacrylate emulsion A, 30 parts of polyacrylate emulsion B, 15 parts of pigment, 1.5 parts of wetting and dispersing agent, 0.7 parts of foaming agent, 3 parts of wax slurry, 20 parts of deionized water;

[0043] Steps 1, 2, and 3 are all the same as in Example 1.

[0044]Specifically, the polyacrylate emulsion A in step 3 is prepared by the following method: (1) the vinyl monomer of 25 parts by weight, the active functional monomer of 7 parts, the diacetone acrylamide of 4 parts, 2 1 part of nonionic emulsifier, 1 part of anionic emulsifier, and 25 parts of deionized water are added to the emulsification kettle, stirred and emulsified to obtain a pre-emulsion; (2) 0.7 parts of initiator are dissolved in 25 parts of (3) The buffering agent that is 0.5 parts by weight is added in the reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freshness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Freshness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com