Multi-dimensional self-limiting grabbing device for automatic production of small workpieces

A technology of small workpieces and grasping devices, applied in packaging, conveyor objects, transportation and packaging, etc., can solve the problems of affecting the success rate of workpiece processing, inability to adapt to small workpieces, and inability to transfer workpieces in batches, so as to avoid workpiece falling. , to achieve linear transfer or rotational transfer, to ensure the effect of the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

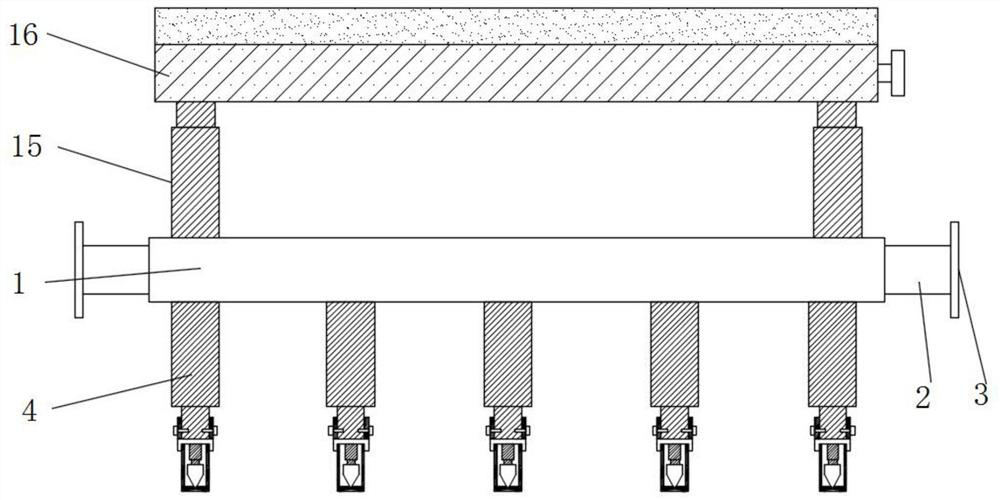

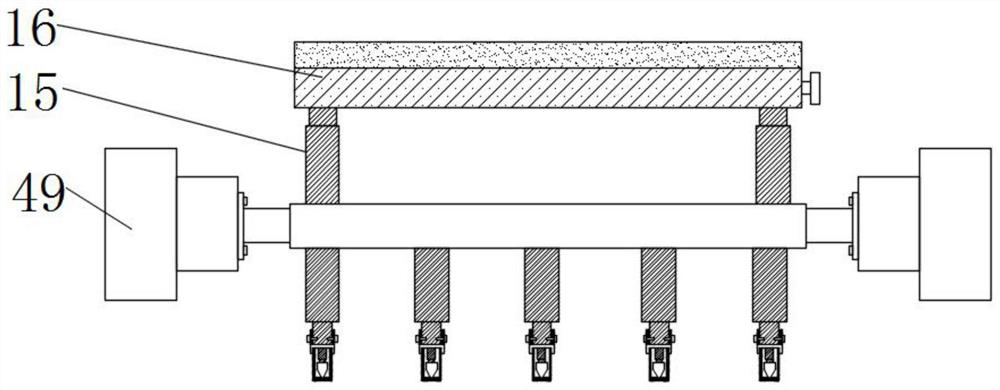

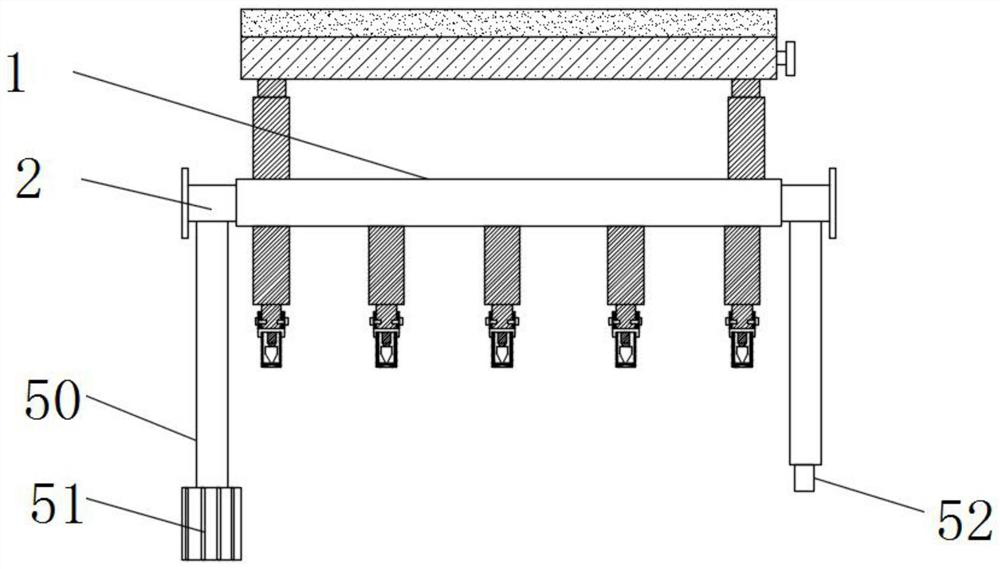

[0034] see Figure 1-10According to an embodiment of the present invention, a multi-dimensional self-limiting grabbing device based on the automatic production of small workpieces includes a support plate 1, and the two sides of the support plate 1 are connected to the installation plate 3 through the installation block 2, and the installation block 2 is provided with a hole that enables the movable rod 50 to be connected, and the mounting plate 3 is provided with a hole that allows the bolt to pass through. The bottom of the support plate 1 is fixedly connected with a plurality of hydraulic telescopic rods-4, and the hydraulic telescopic rod-1 The movable end of 4 is fixedly connected with connecting sleeve one 6 by connecting bolt 5, and the movable end of hydraulic telescopic rod one 4 has the hole that can make connecting bolt 5 pass through, and connecting sleeve one 6 is provided with and can be threaded with connecting bolt 5. screw holes for connection;

[0035] The b...

Embodiment 2

[0039] see Figure 7-9 , the anti-falling mechanism includes a cavity one 23, a cavity two 24, a spring two 25, a tooth plate 26, a gear one 27, a movable shaft 28, a push block 29, a movable block three 30, a concave-convex surface 31 and an inclined surface 32. The bottoms of the fixed splint 21 and the movable splint 22 are all provided with a cavity one 23, and the top of one end of the cavity one 23 has a cavity two 24, and the top of the cavity two 24 is connected with the teeth by the spring two 25. The plate 26 is connected, and the tooth plate 26 is connected to the second limit mechanism between the fixed splint 21 and the movable splint 22. The tooth plate 26 is meshed with the gear one 27, and the center of the gear one 27 passes through the movable The shaft 28 is movably connected with the inner wall of the cavity one 23, and the side of the gear one 27 away from the tooth plate 26 is fixedly connected with a push block 29, and the cavity one 23 is connected with...

Embodiment 3

[0041] see Figure 8-9 , the reset mechanism includes a connection block 1 33, a connection block 2 34 and a spring 3 35, the top of the cavity 1 23 away from the cavity 2 24 is fixedly connected to the connection block 1 33, and the movable block 3 The top of 30 is fixedly connected with connecting block 2 34, the top of connecting block 2 34 is in contact with the top of cavity 1, and the connection between said connecting block 2 34 and said connecting block 1 33 is connected by spring 3 35, which can be realized by reset mechanism. The reset of movable block three 30 can make movable block three 30 reset when movable block three 30 is not promoted by pushing block 29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com