Inspection well frame based on multipoint distribution cushion blocks and construction process of inspection well frame

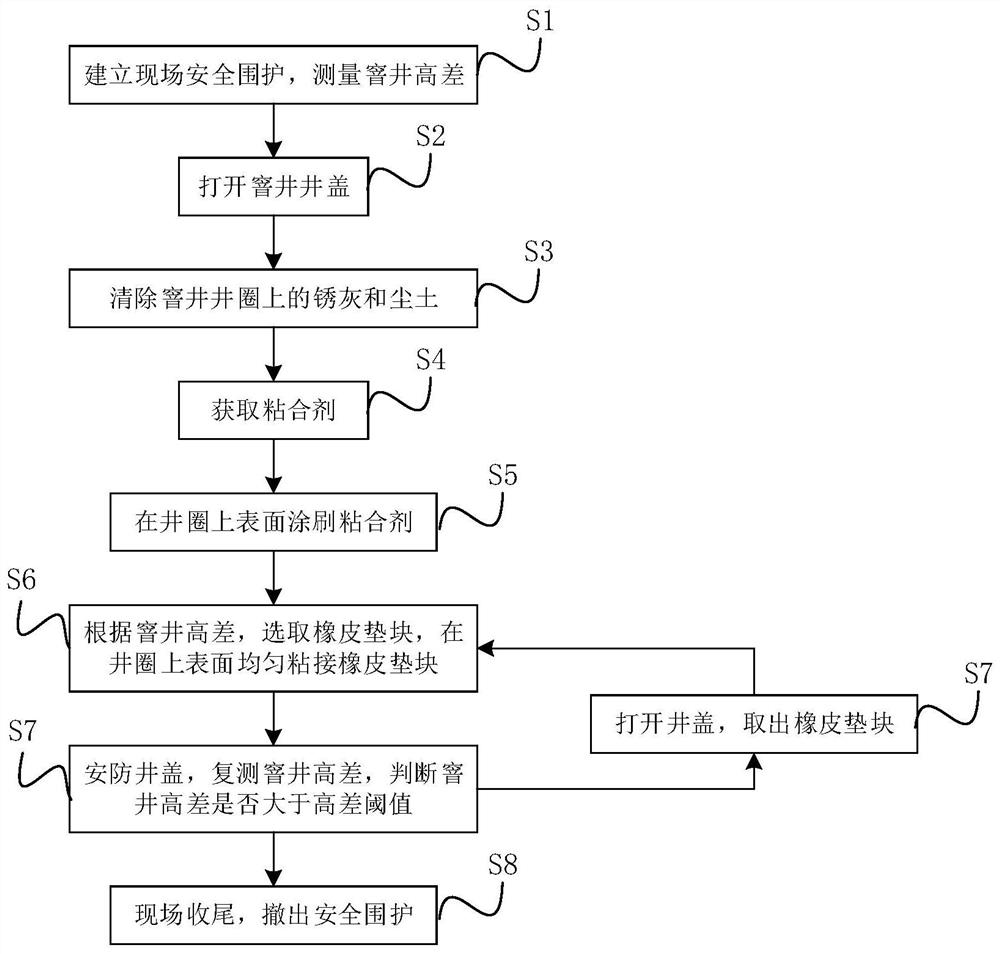

A construction process and well frame technology, which is used in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of insufficient physical and chemical strength of rubber gasket materials, installation process defects, fracture and corrosion, etc., to avoid artificial Destruction, low maintenance cost, effect of removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

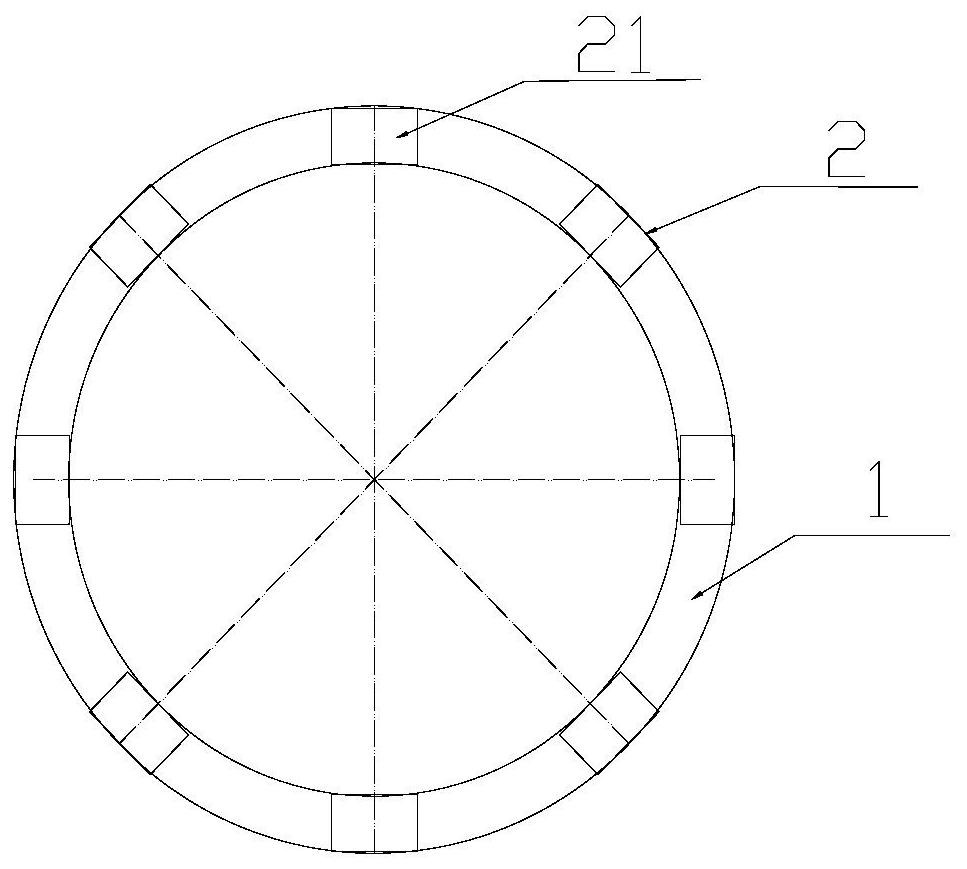

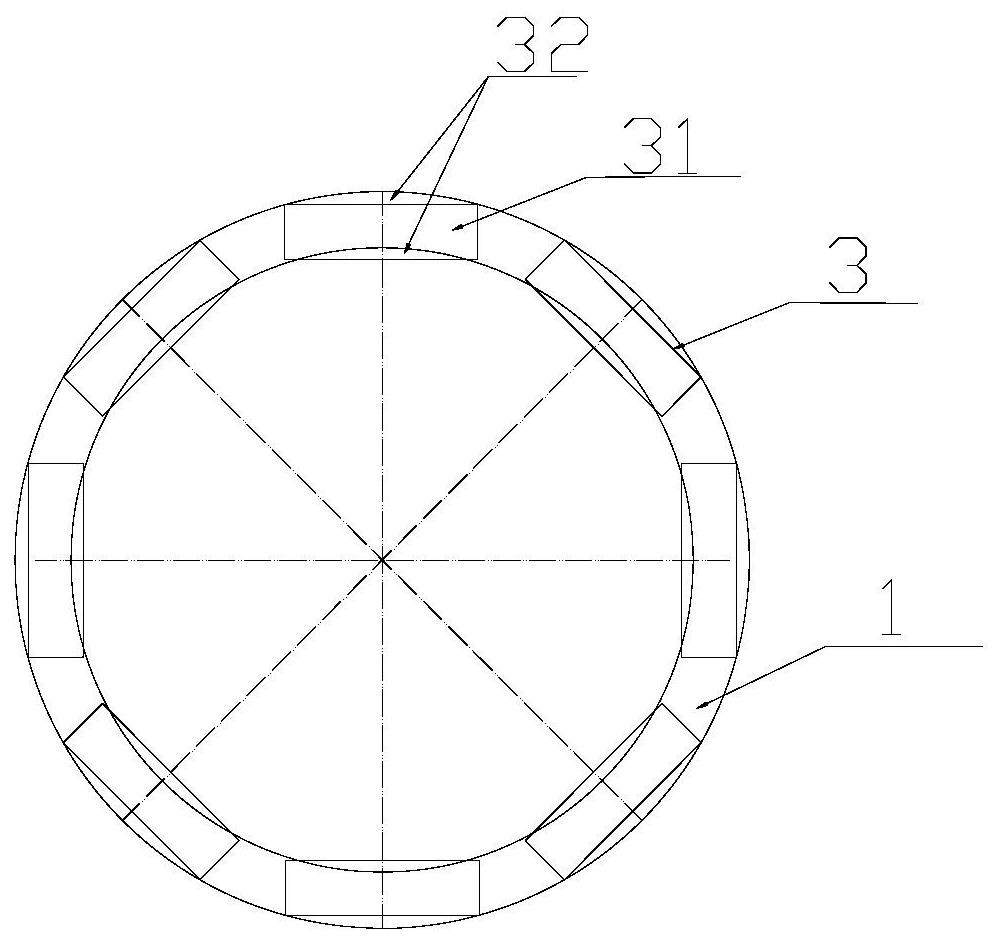

[0046] This embodiment provides a well frame for inspection wells based on multi-point distribution pads, which is used for installing manhole covers. The well frame for inspection wells includes a main body of the well frame. The surface is evenly distributed with a plurality of rubber pads for supporting the well cover, and the multiple rubber pads are connected to the well ring 1 through adhesives. The rubber pads have a rectangular parallelepiped structure, and the rubber pads are arranged tangentially along the center line of the well ring 1 , the width of the rubber pad matches the thickness of the annular upper surface of the well ring 1;

[0047] When in use, after the well cover is installed on the well frame of the inspection well, the well cover and the well frame of the inspection well are evenly supported by a plurality of rubber pads to keep the well cover stable.

[0048] The rubber block is a cuboid structure. The rubber block adopts the tire cut-off material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com