Heating element mechanical strength testing device and using method

A heating element and testing device technology, which is applied in the field of heating cigarettes, can solve problems such as fracture and damage of heating elements, and achieve the effects of low cost, few parts, and accurate and reliable mechanical strength data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below through the examples and accompanying drawings, the purpose is only to better understand the content of the present invention, but not to limit the present invention.

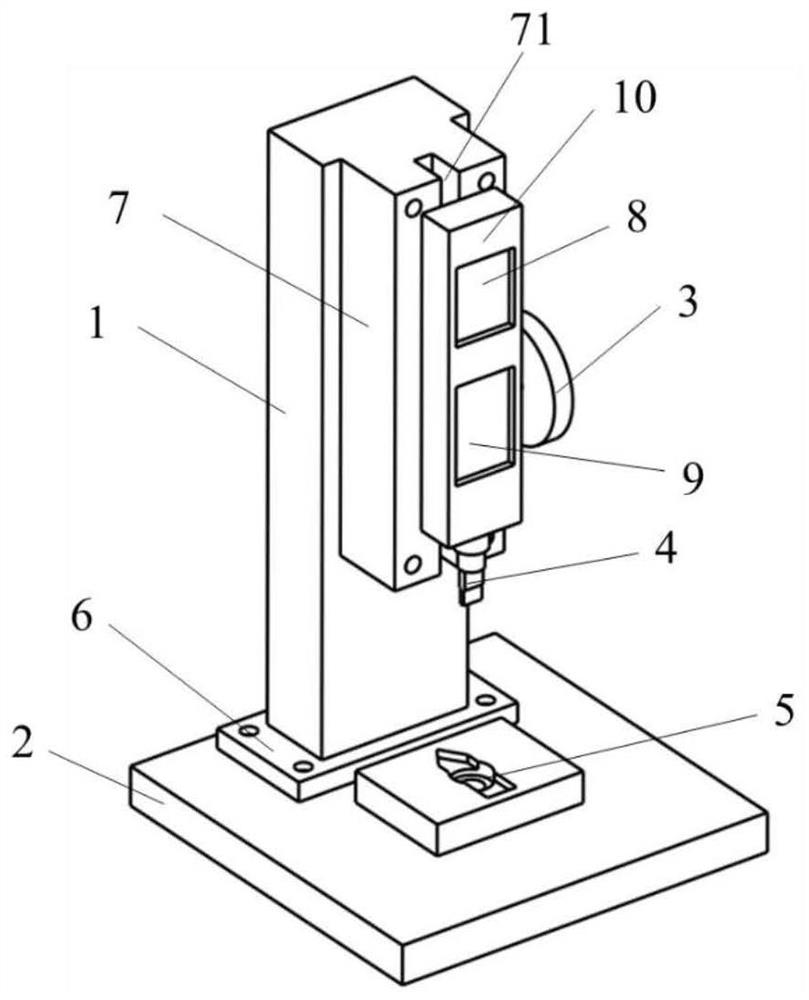

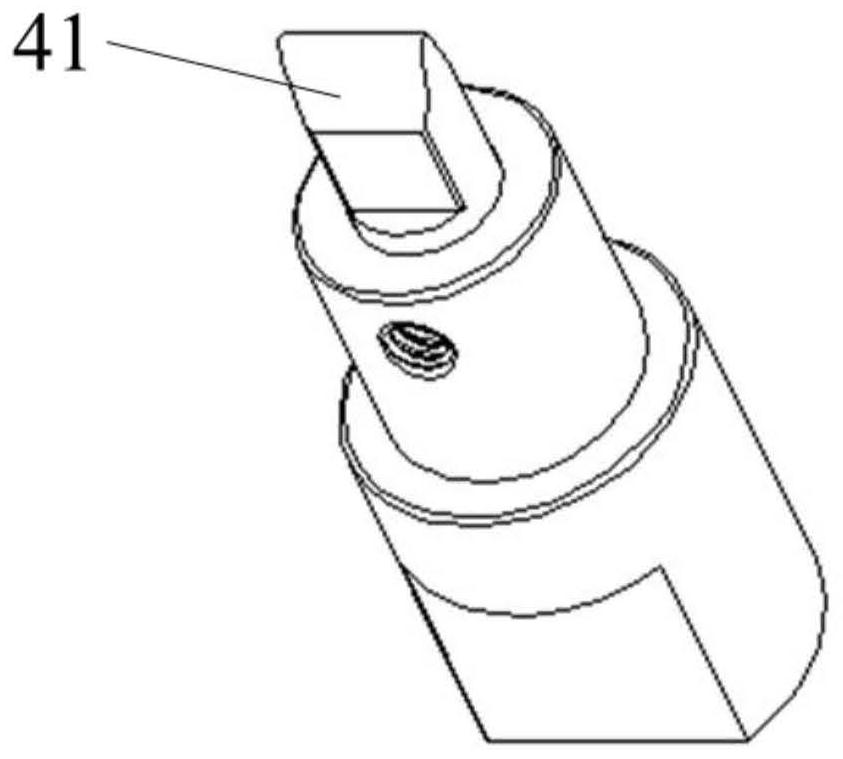

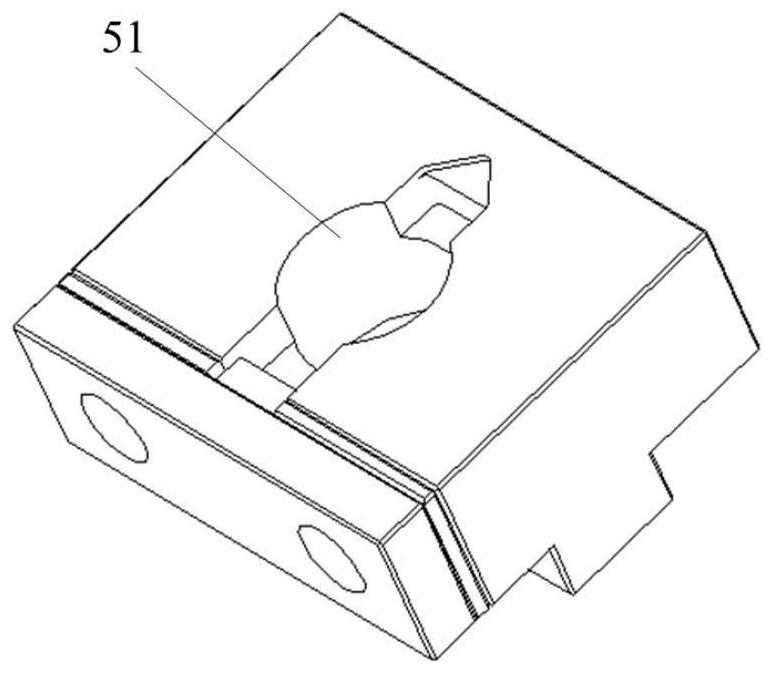

[0031] Such as figure 1 The shown heating element mechanical strength testing device of the present invention includes a fixed arm 1, a fixed base 2, a hand-operated device 3, a punch 4, a heating element support seat 5, a connecting seat 6, a transmission box 7 and a movable box 10; The arm 1 is vertically connected to the fixed base 2 with screws through the connecting seat 6; the transmission box 7 is fixedly mounted on the fixed arm 1, and the transmission box 7 has a slide rail 71 perpendicular to the plane of the fixed base 2 ; Hand-operated device 3 and movable case 10 are installed on the transmission case 7, described hand-operated device 3 can control movable case 10 to slide on slide rail 71; Punch 4 is installed on the bottom of described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com