Magnetostriction material performance testing device and method

A magnetostrictive material and testing device technology, applied in the field of magnetic measurement, can solve the problems of heavy mass, large frame structure yoke, complex prestress loading mechanism, etc., and achieve the effect of light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1 - Pressurization with gas

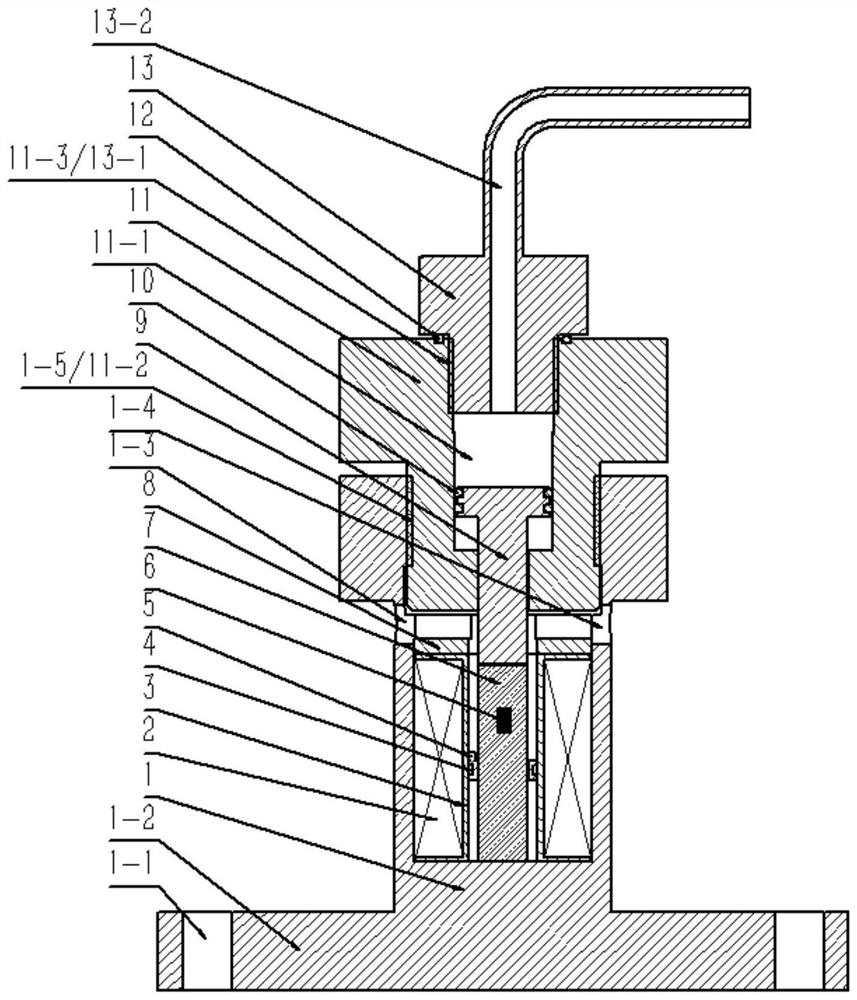

[0067] figure 1 It is a schematic structural diagram of the first embodiment of a magnetostrictive material magnetic property testing device of the present invention. like figure 1 As shown, the test device of this embodiment includes a main body part 1 with a mounting base, an excitation coil 2, a keel 3, a magnetic induction measurement coil 4, a Hall probe 5, a resistance strain gauge 6, a material test sample 7, and a screw lock The gland 8, the T-shaped pressurizing rod 9, the first sealing ring 10, the first fastener 11, the second sealing ring 12, the second fastener 13, and the pressure gas connection pipe 13-2.

[0068] Wherein, the lower part of the main body part 1 is a disc-type base 1-2, the disc-type base 1-2 has four installation holes 1-1 symmetrically and evenly distributed, and the upper part of the main body part 1 is a tubular cylinder with an open upper end, The upper end of the inner side of the tubular cy...

Embodiment 2

[0070] Example 2 - Pressurization with elastic elements

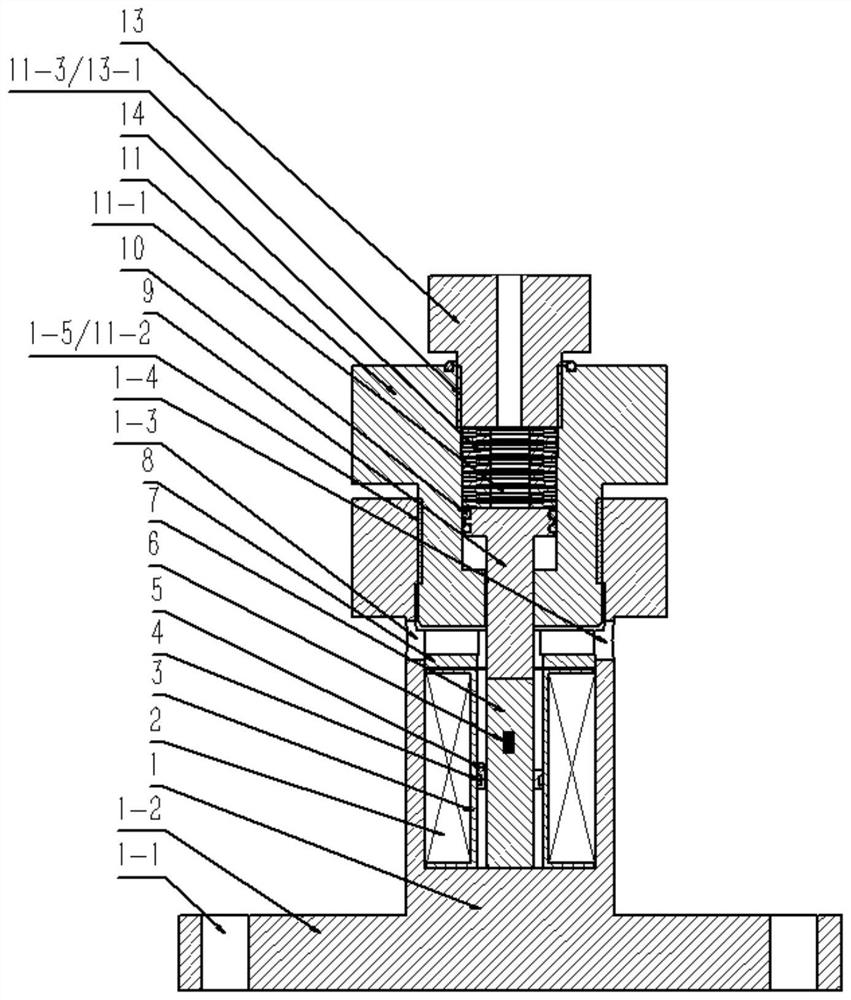

[0071] figure 2 It is a schematic structural diagram of the second embodiment of a magnetostrictive material magnetic property testing device of the present invention. like figure 2 As shown, the test device of this embodiment includes a main body part 1 with a mounting base, an excitation coil 2, an excitation coil keel 3, a magnetic induction measurement coil 4, a Hall probe 5, a resistance strain gauge 6, a material test sample 7, a thread Lock the pressing cover 8 , the T-shaped pressing rod 9 , the first fastener 11 , the second fastener 13 , and the elastic element 14 . The lower part of the main body part 1 is a disc-type base 1-2, the base has four symmetrically distributed mounting holes 1-1, the upper part is a tubular cylinder with an open upper end, and the inner upper end of the tubular cylinder has an inner thread 1 of the main body part. -5. There are through holes 1-3 for the excitation coil power...

Embodiment 3

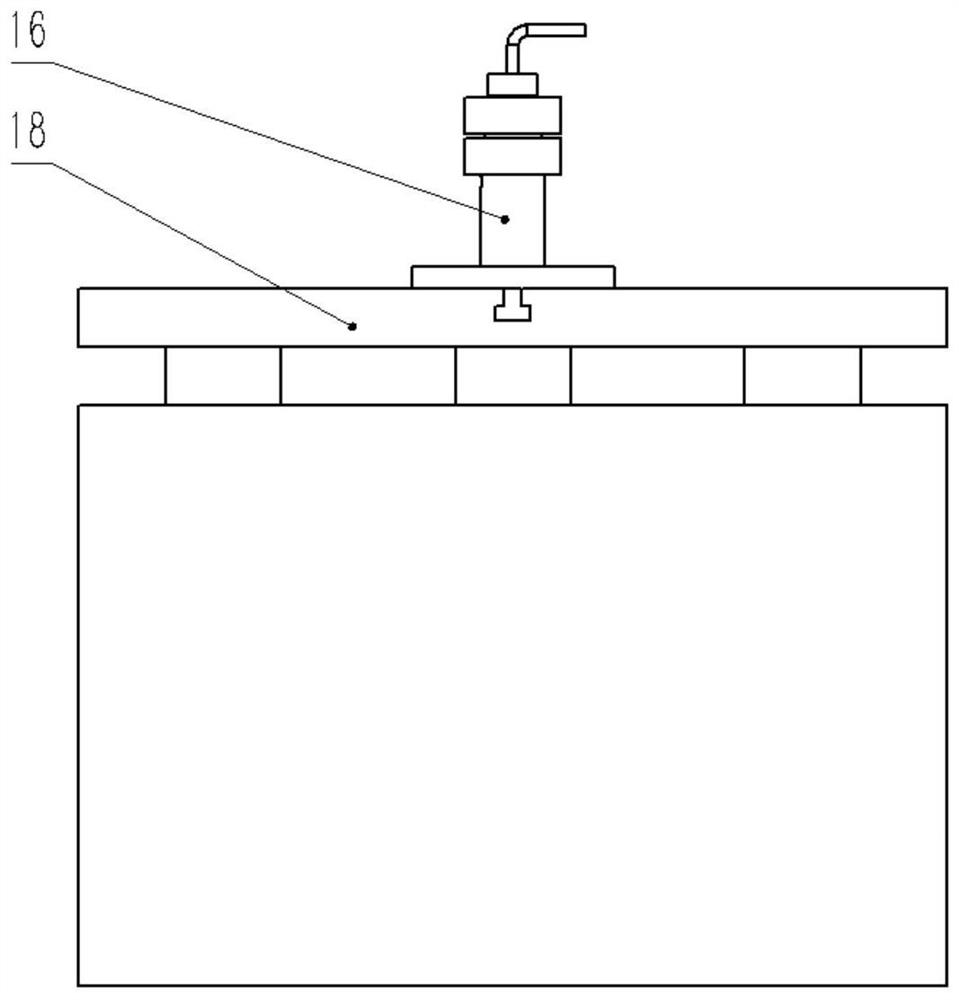

[0073] Example 3 - The test device is connected to a shock, vibration test bench

[0074] image 3 It is a schematic structural diagram of the third embodiment of a device for testing the magnetic properties of magnetostrictive materials according to the present invention. like image 3 As shown, in this embodiment, the test device 16 of the present invention is installed on the shock and vibration test bench 18 , which includes the test device 16 and the shock and vibration test bench 18 . Put the magnetostrictive material test sample 7 into the test device 16, screw the first fastener 11 into the main body part 1 through the thread, and install the T-shaped pressure rod 9 with the first sealing ring 10 into the first in fastener 11. Place the second sealing ring 12 in the sealing groove at the upper end of the first fastener 11 , and then screw the second fastener 13 into the first fastener 11 until the second sealing ring 12 is pressed tightly. The testing device 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com