Design method of high-frequency high-power three-phase transformer

A technology of three-phase transformer and design method, applied in the direction of transformer, fixed transformer, design optimization/simulation, etc., can solve the problem that the design method and realization of high-frequency three-phase transformer are not reported in detail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

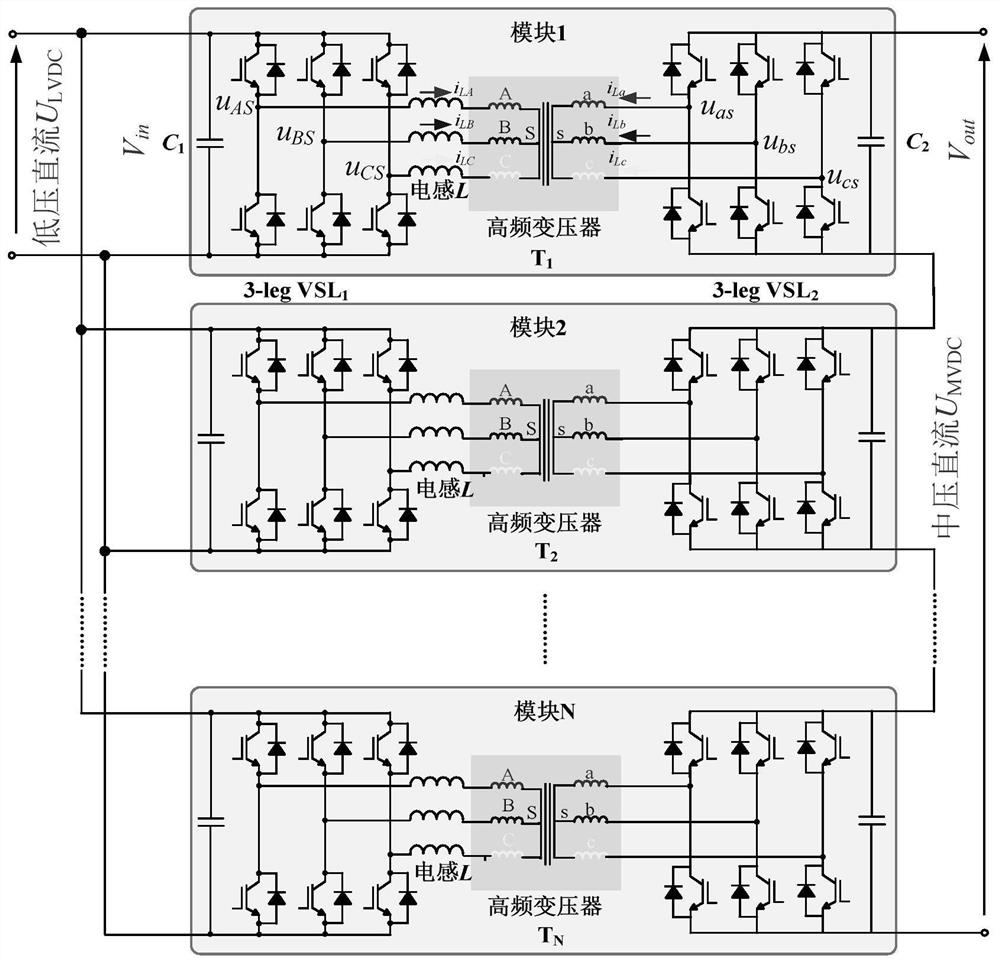

[0090] The solid-state transformer topology based on the three-phase dual active full-bridge DC-DC converter as the basic module is as follows: figure 1 As shown, the high-voltage side is connected in series to increase the voltage level, and the low-voltage side is connected in parallel to increase the power level. The three-phase dual-active full-bridge DC-DC converter is composed of a high-frequency three-phase transformer T, an inductor L, a three-leg voltage source converter (three-leg voltage source inverters, 3-leg VSL) at both ends of the transformer, and a DC filter capacitor C 1 and C 2 composition. The switching tubes of the three-leg voltage source are connected in parallel with the Snubber capacitors to realize zero-voltage turn-on and turn-off of the switching tubes. By adjusting the phase shift angle between the gating signals of the three-leg converter on the inverter and rectifier sides Controls the direction of power flow. V in and V out is the voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com