Piezoelectric energy collection device and application and method on floating slab track

A kind of energy harvesting and piezoelectric technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve component damage, low bearing capacity, slight shortage, etc. problems, to achieve the effect of increasing output capacity, carrying capacity, and saving vertical space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

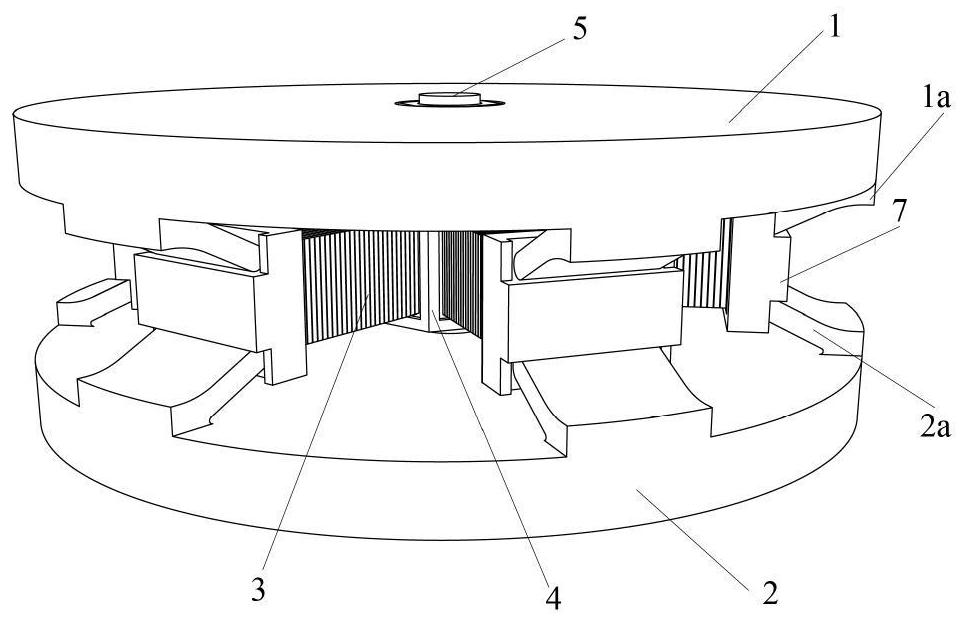

[0063] Such as Figure 3(a) , 3(b) , 4, the piezoelectric energy harvesting device mainly includes the upper cover plate 1, the lower cover plate 2, the pressure plate 7, the piezoelectric ceramic stack 3, the central block 4 and the wires etc., the upper cover plate 1 Between the upper cover plate 1 and the lower cover plate 2, a central block 4 is arranged at the center, and six groups of piezoelectric ceramics arranged radially are arranged symmetrically around the center block 4 between the upper cover plate 1 and the lower cover plate 2. Stack 3, between the upper cover plate 1 and the lower cover plate 2, there is also a device that matches the position and quantity of the piezoelectric ceramic stack 3 and converts the vertical pressure of the upper and lower cover plates 2 into a horizontal thrust in the radial direction. Pushing device, one end of the piezoelectric ceramic stack 3 is supported on the central block 4, and the other end is supported on the pushing devic...

Embodiment 2

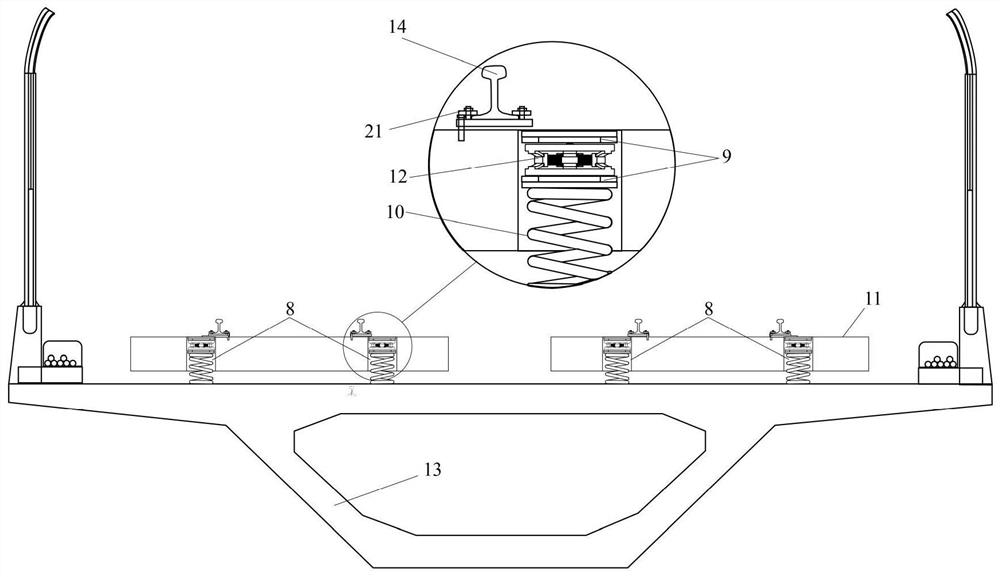

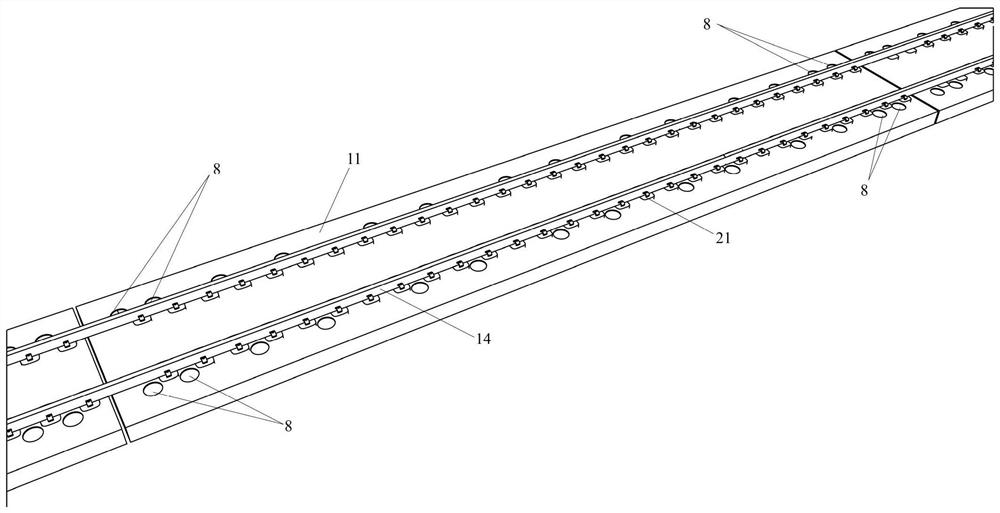

[0066] Such as figure 1 , 2 This embodiment is an application of Embodiment 1. The piezoelectric energy harvesting device is applied to the floating plate track. The floating plate track includes a steel spring floating plate 11, and the steel spring floating plate 11 is equipped with A plurality of steel spring vibration isolators 8, the steel spring vibration isolators 8 include upper and lower backing plates 9 and steel springs 10, the piezoelectric energy harvesting device 12 is arranged in the steel spring vibration isolators 8, the upper and lower backing plates 9, in series with the steel spring.

[0067] The following is a concrete analysis through examples, such as Figure 5 As shown, through analysis, when a B-type subway vehicle passes the floating plate at a constant speed of 120km / h on the main line, the energy harvested by this energy harvesting method from a single steel spring isolator within 5 seconds is 1.07J , the average power is 0.21W, the peak output v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com