A kind of varenicline tartrate tablet and preparation method thereof

A technology for varenicline tartrate and tablets, which is applied in the directions of pill delivery, pharmaceutical formulations, and non-active ingredients medical preparations, etc., can solve the problems of reduced dissolution rate of tablets, unsuitable for long-term use, cumbersome process, etc. High dissolution, low friability and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

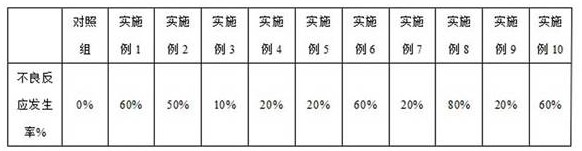

Examples

Embodiment 1

[0051]

[0052] 1) when one third of the weight of magnesium stearate, microcrystalline cellulose and varenicline tartrate are mixed after 20 minutes at a rotating speed of 15rpm, sieve and granulate, wherein the screen aperture is 0.8-2.0mm during granulation, to prepare a mixture;

[0053] 2) mixing the mixture obtained in step 1) with mannitol, polyvinylpyrrolidone, and low-substituted hydroxypropyl cellulose for 10-30 minutes at a rotating speed of 15 rpm;

[0054] 3) adding residual magnesium stearate to the mixture obtained in step 2), and mixing for 10-20 minutes at a rotating speed of 15 rpm;

[0055] 4) compressing the obtained mixed granules in step 3), and controlling the hardness of the tablet to be 3~10Kp;

[0056] 5) Transfer the plain tablet compressed in step 4) to a coating machine for coating operation.

Embodiment 2

[0058]

[0059] 1) when one third of the weight of magnesium stearate, microcrystalline cellulose and varenicline tartrate are mixed after 20 minutes at a rotating speed of 15rpm, sieve and granulate, wherein the screen aperture is 0.8-2.0mm during granulation, to prepare a mixture;

[0060] 2) mixing the obtained mixture of step 1) with calcium hydrogen phosphate, polyvinylpyrrolidone, and low-substituted hydroxypropyl cellulose for 10-30 minutes at a rotating speed of 15 rpm;

[0061] 3) adding residual magnesium stearate to the mixture obtained in step 2), and mixing for 10-20 minutes at a rotating speed of 15 rpm;

[0062] 4) compressing the obtained mixed granules in step 3), and controlling the hardness of the tablet to be 3~10Kp;

[0063] 5) Transfer the plain tablet compressed in step 4) to a coating machine for coating operation.

Embodiment 3

[0065]

[0066] 1) when one third of the weight of magnesium stearate, microcrystalline cellulose and varenicline tartrate are mixed after 20 minutes at a rotating speed of 15rpm, sieve and granulate, wherein the screen aperture is 0.8-2.0mm during granulation, to prepare a mixture;

[0067] 2) mixing the mixture obtained in step 1) with sorbitol, polyvinylpyrrolidone, and low-substituted hydroxypropyl cellulose for 10-30 minutes at a rotating speed of 15 rpm;

[0068] 3) adding residual magnesium stearate to the mixture obtained in step 2), and mixing for 10-20 minutes at a rotating speed of 15 rpm;

[0069] 4) compressing the obtained mixed granules in step 3), and controlling the hardness of the tablet to be 3~10Kp;

[0070] 5) Transfer the plain tablet compressed in step 4) to a coating machine for coating operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com