Raw material processing equipment based on teaching and practical training

A technology of processing equipment and raw materials, applied in the field of raw material processing equipment based on teaching and training, can solve the problems of bulky and lacking, and achieve the effect of reducing the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

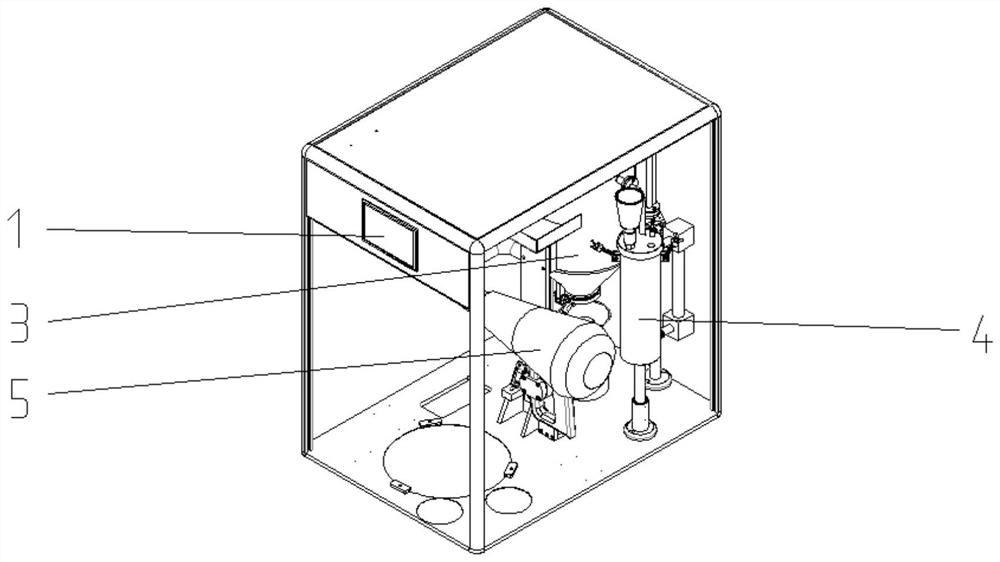

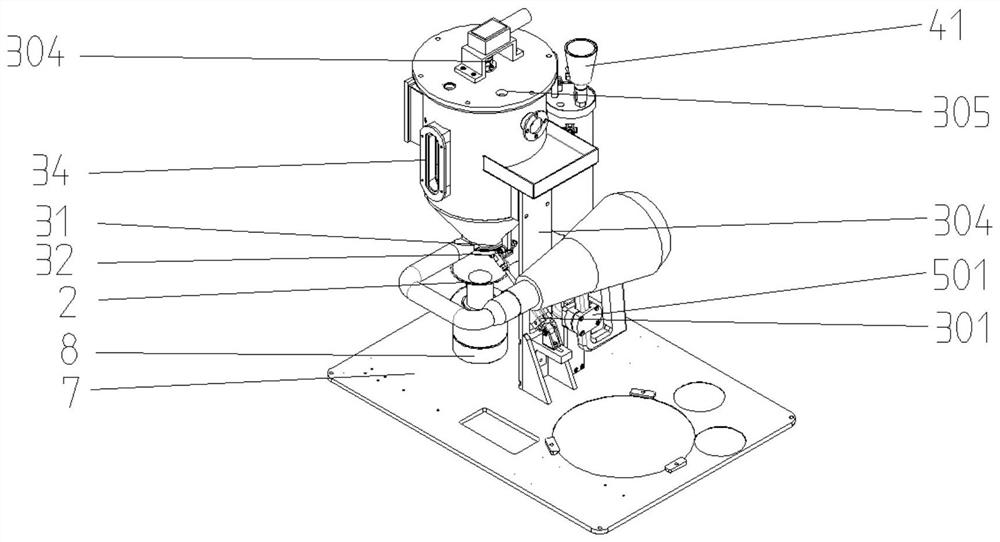

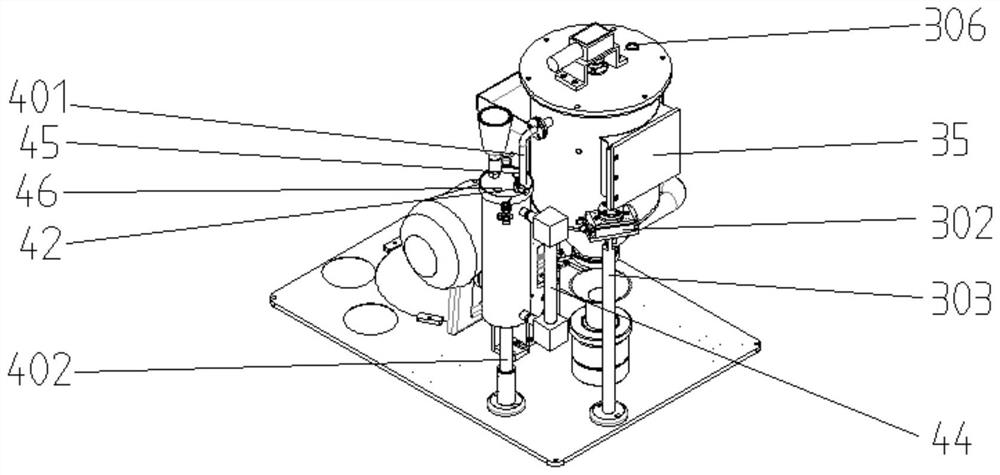

[0033] A raw material processing equipment based on teaching and training, comprising a touch control screen, a PLC controller, a fluidized furnace, an adhesive tank, a heat gun, a spray assembly, a base plate and a casing, the touch control screen is arranged on the casing, and the touch control The control panel is connected with the PLC controller, the side of the fluidized fluidized furnace is connected with the adhesive tank connecting pipe, the bottom of the fluidized fluidized furnace is connected with the heat gun, a stirring assembly is arranged inside the fluidized fluidized furnace, and a stirring motor is provided on the fluidized fluidized furnace. The stirring motor is connected with the stirring assembly, a temperature sensor and a humidity sensor are provided on the fluidized fluidized furnace, a liquid level observation tube, a liquid level sensor and a pressure sensor are provided on the adhesive tank, and a discharge port is provided under the fluidized fluidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com