Environmental-friendly crushing device for waste battery disposal

A waste battery and crushing device technology, which is applied in battery recycling, grain processing, dry gas arrangement, etc., can solve the problems of difficult recycling of useful raw materials, inability to crush waste batteries, and reduce the recycling efficiency of waste batteries, so as to achieve continuous crushing process , the effect of high degree of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

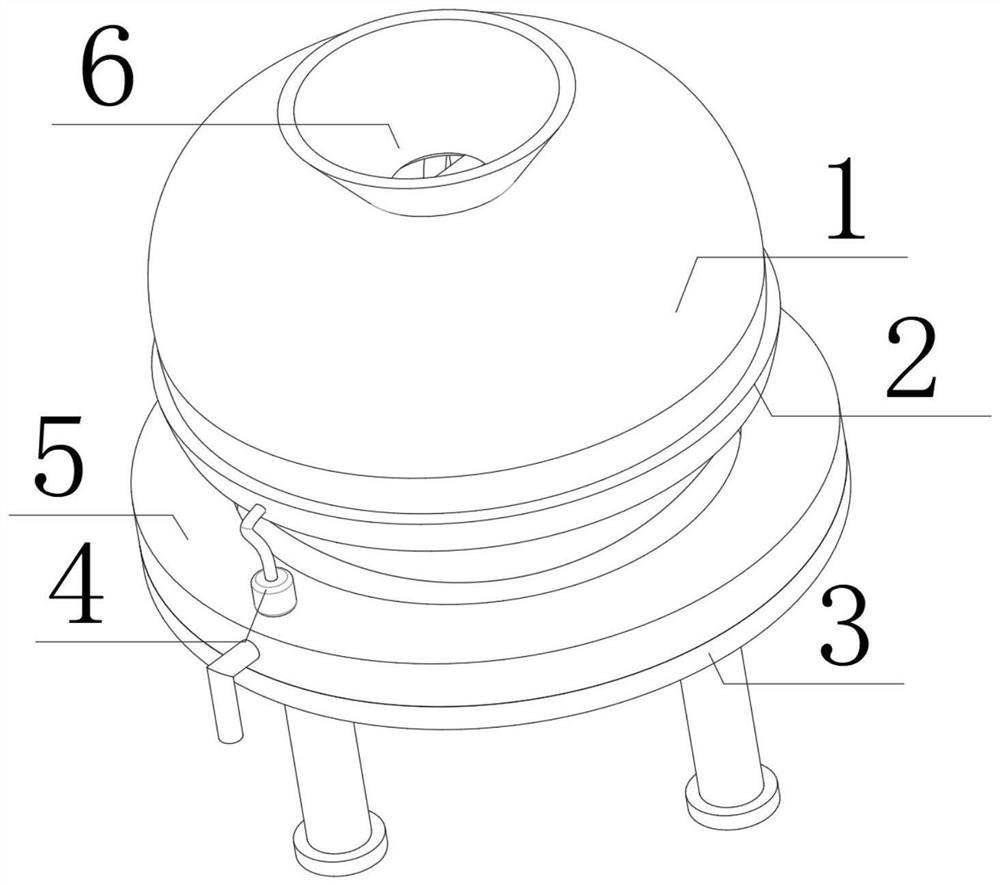

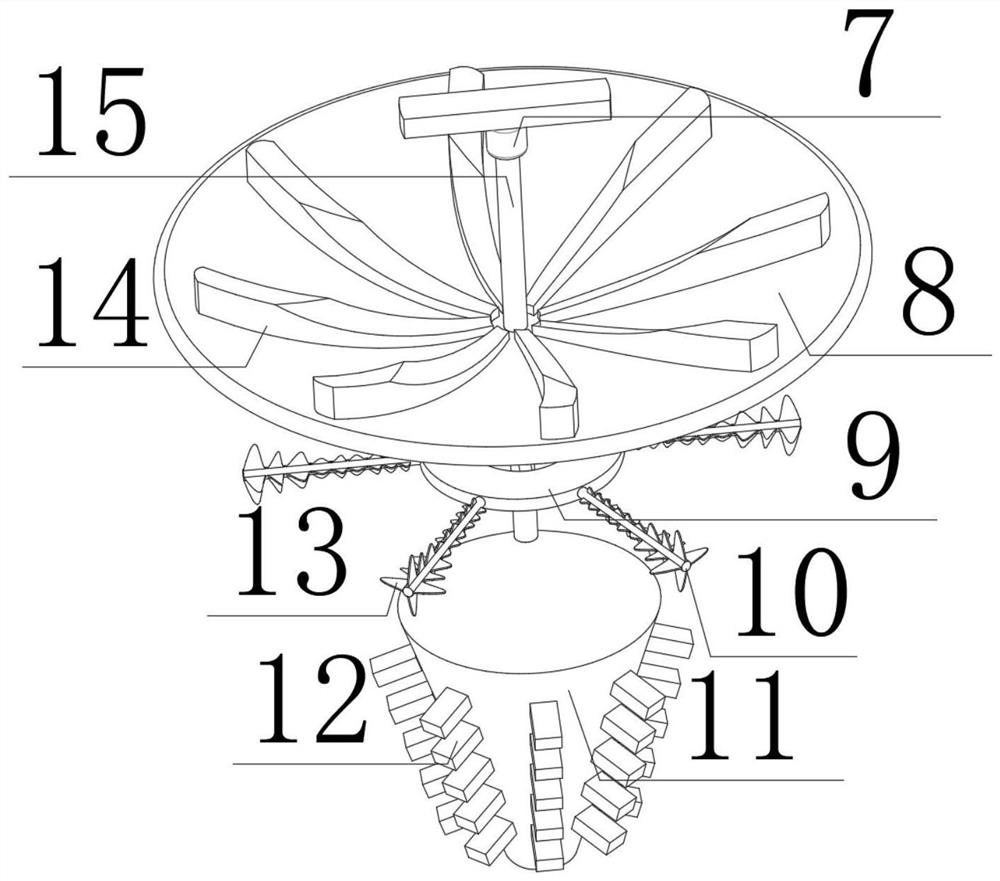

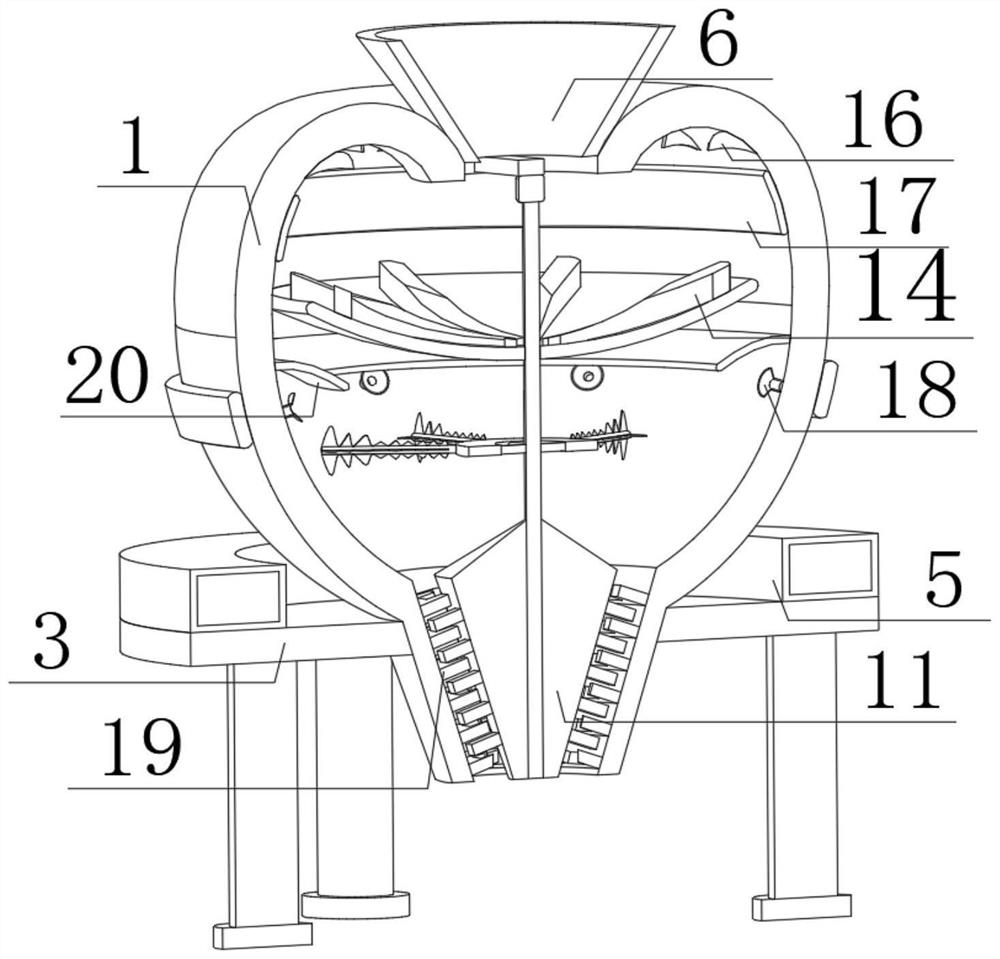

[0027] refer to Figure 1-4 , an environment-friendly crushing device for waste battery treatment, comprising a workbench 3, a crushing cylinder 1 is arranged on the top outer wall of the workbench 3, a feeding hole is arranged on the top outer wall of the crushing cylinder 1, and a feeding hole is arranged on the inner wall of the feeding hole. bucket 6, and the inner wall of the feed hole is provided with a mounting plate, the bottom outer wall of the mounting plate is provided with a motor 7, the output shaft of the motor 7 is connected with a rotating rod 15 through a coupling, and the outer wall of the rotating rod 15 is provided with a rotating bucket 8, The top outer wall of the bucket 8 is provided with equidistantly distributed stoppers 14, the inner wall of the crushing cylinder 1 is provided with a reinforcing plate 17, and the inner wall of the crushing cylinder 1 at the top of the reinforcing plate 17 is provided with equidistantly distributed crushing knives 16, a...

Embodiment 2

[0036] refer to Figure 5 , an environment-friendly crushing device for waste battery treatment. Compared with Embodiment 1, this embodiment also includes that the top outer wall of the feeding hopper 6 is provided with a top cover 22 .

[0037] During use, a top cover 22 is provided on the top of the feed hopper 6, the top cover 22 can prevent hot air from escaping the crushing cylinder 1, and can prevent dust from entering the air through the crushing cylinder 1 to pollute the air, and the environmental performance is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com